LED (Light-Emitting Diode) T5 split lamp tube with embedded driver

A lamp tube and split technology, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc. Instability and other problems, to achieve the effect of reducing labor costs, high power efficiency, and low power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the drawings.

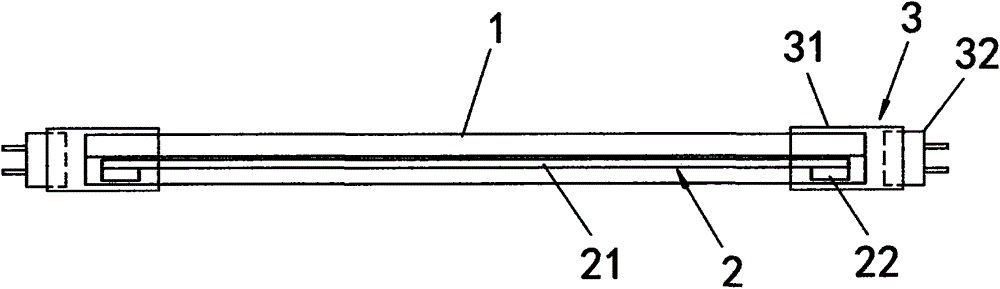

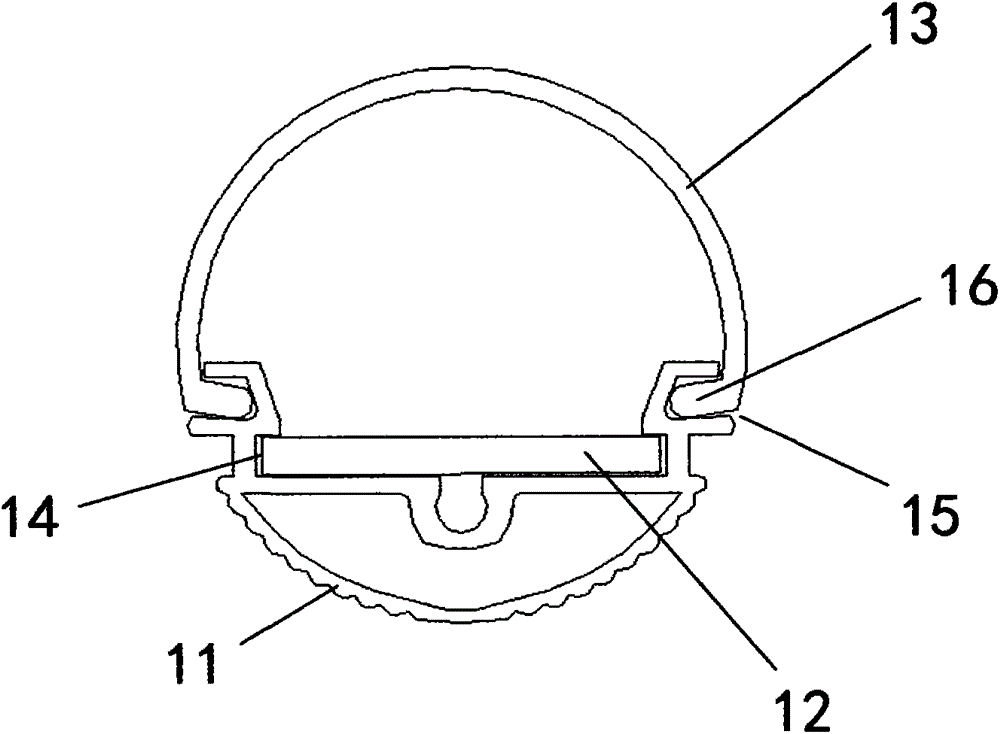

[0012] Such as figure 1 , figure 2 As shown, a built-in driver LED T5 split tube is characterized in that it includes a tube body 1, a power lamp bead integrated board 2 and a plug 3. The tube body 1 has a diameter of 20 mm, and the tube body 1 is radiated by heat. An aluminum profile 11, an aluminum base plate 12 and a light-transmitting cover 13 are formed. The heat dissipation aluminum profile 11 is provided with a slot 14 in the middle, and there are card slots 15 on both sides, and the aluminum base plate 12 is inserted into the slot 14 of the heat dissipation aluminum profile 11 to be fixed; The translucent cover 13 is made of transparent plastic or glass, and the translucent cover 13 is provided with claws 16; the power lamp bead integrated board 2 consists of a lamp bead plate 21 and a driving power supply 22 fixed at both ends of the lamp bead plate 21 The power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com