Cantilever type rotor used for backing turbine air blowing loss test

A blast loss, cantilever technology, applied in the direction of blade support elements, engine elements, machines/engines, etc., can solve the problems of long cycle, complex structure and lubrication of both ends of the support system, high cost, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

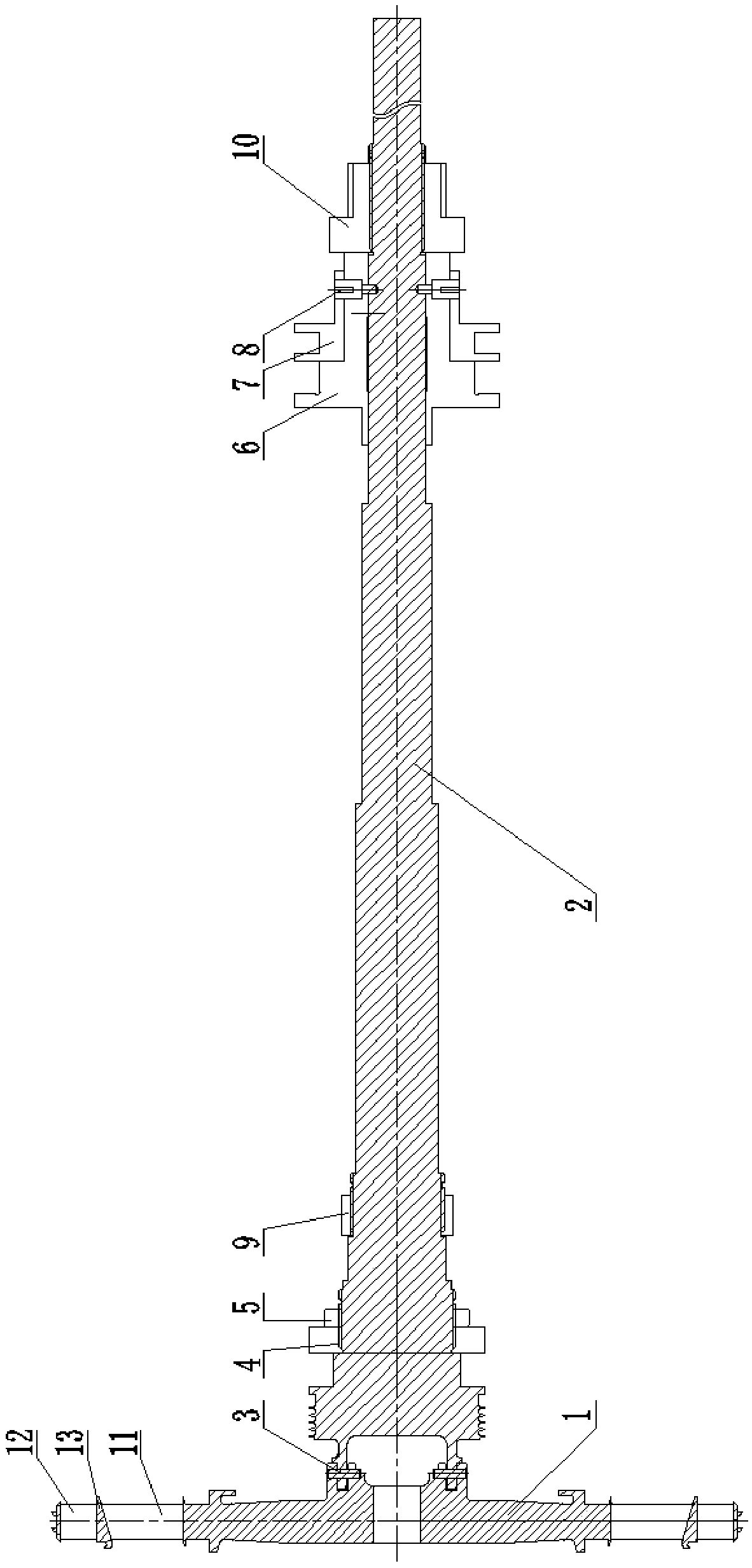

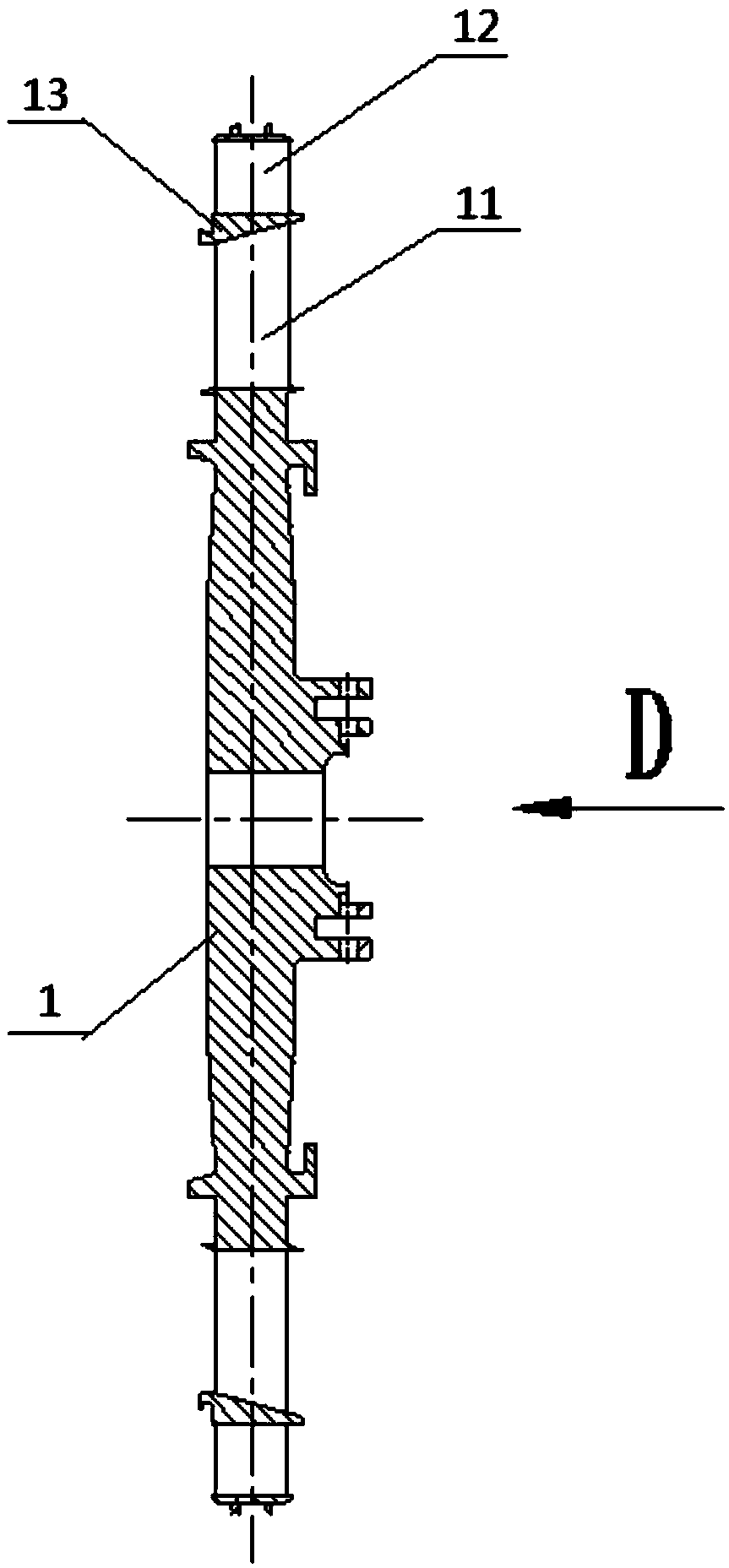

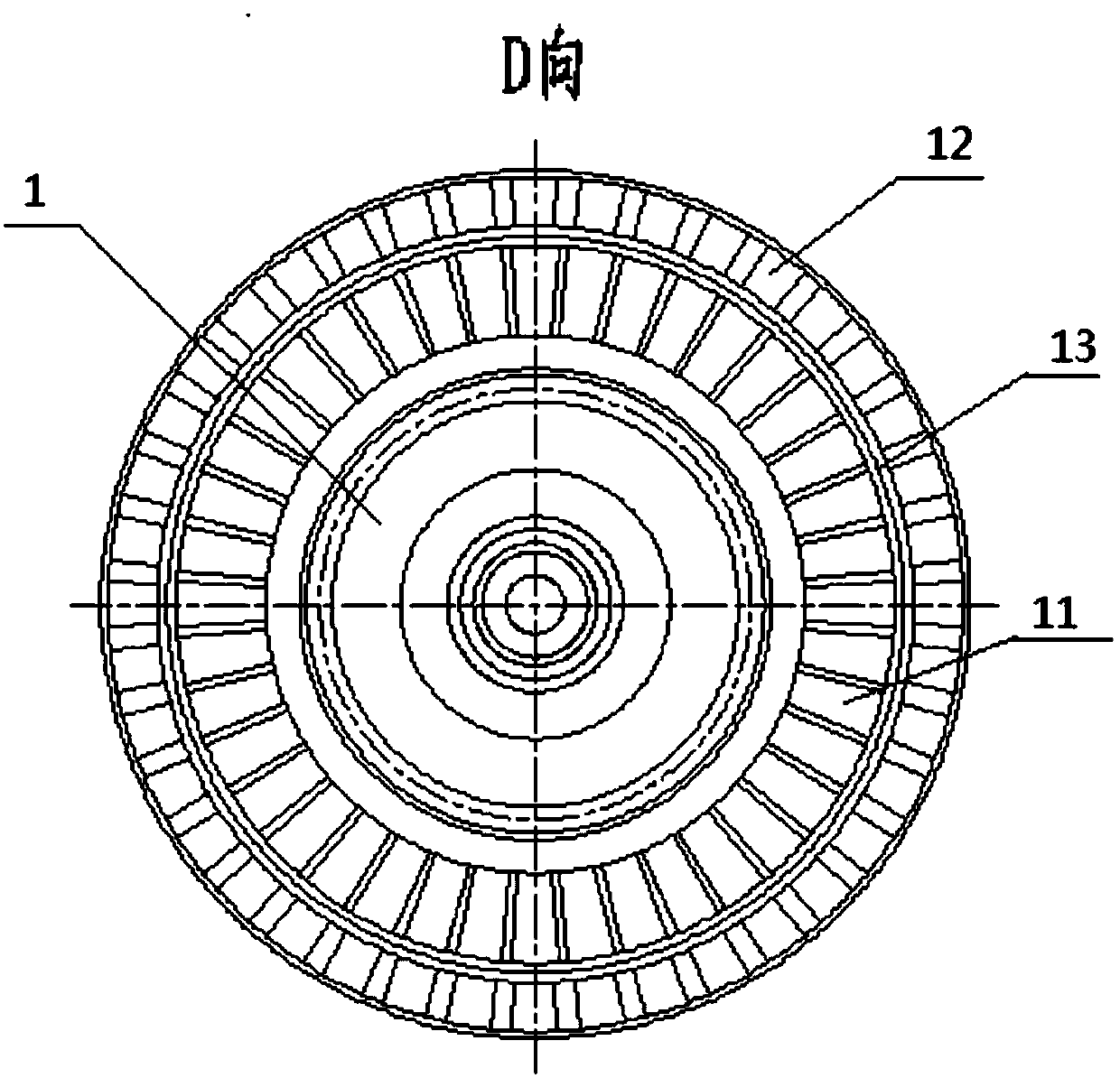

[0017] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a cantilevered rotor used for the blowing loss test of a reversible turbine, which includes a turbine integral blade disk, and it also includes a reversible turbine output shaft 2, a disk shaft connecting pin 3, a forward turning blade 11, The intermediate ring 13 and the reverse turbine blade 12, the forward moving blade 11 is installed on the overall turbine blade disc, the reverse turbine blade 12 is installed on the forward moving blade 11 through the intermediate ring 13, the overall turbine blade disc, the forward moving blade 11, The intermediate ring 13 and the reversing turbine blades 12 together form a reversible turbine double-layer integral blade disc 1, and one end of the reversible turbine output shaft 2 is connected to the reversible turbine double-layer integral blade disc 1 through a disk shaft connecting pin 3, and the reversible turbine output One end of the shaf...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 and Figure 9 The present embodiment will be described. In this embodiment, the blade profiles of the forward moving blade 11 and the reverse turbine blade 12 are in opposite directions. Such setting can satisfy the power output in different rotation directions, thus having the functions of forward driving and reverse driving. Other compositions and connections are the same as in the first embodiment.

[0020] The included angle A between the blade surfaces of the forward moving blade 11 and the reverse turbine blade 12 in this embodiment is 126 degrees.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 and Figure 4 To illustrate this embodiment, the reversible turbine output shaft 2 in this embodiment is a stepped shaft, and the diameter of the reversible turbine output shaft 2 decreases sequentially from left to right. Such setting facilitates the installation and axial positioning of the bearing. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com