Preparation method of ferroferric oxide nanoparticles

A technology of ferroferric oxide and nanoparticles, which is applied in the direction of iron oxide/hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of high preparation cost, high toxicity of organic solvents, complicated process, etc., and achieve the solution of agglomeration and sintering , easy large-scale production, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

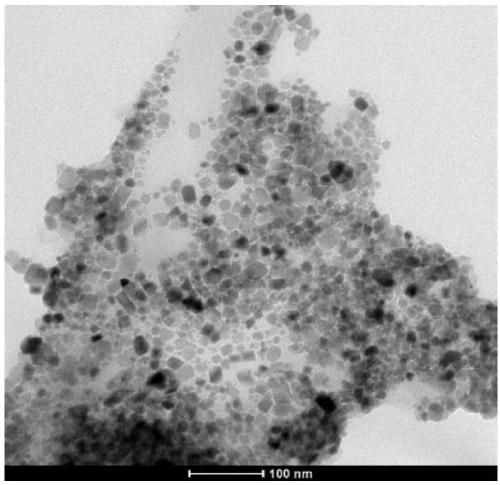

Image

Examples

Embodiment 1

[0027] Example 1: Prepare a solution with a concentration of 0.1 mol / L with iron acetylacetonate and ethanol, impregnate potassium sulfate powder, remove excess impregnating liquid, and dry the powder. The dried powder is reduced with hydrogen at 400°C to 500°C, washed with water and dried to obtain ferric oxide nanoparticles.

Embodiment 2

[0028] Example 2: Prepare a solution with a concentration of 0.1 mol / L with iron acetylacetonate and chloroform, impregnate potassium sulfate powder, remove excess impregnating liquid, and dry the powder. The dried powder is reduced with hydrogen at 400°C to 500°C, washed with water and dried to obtain ferric oxide nanoparticles.

Embodiment 3

[0029] Example 3: A solution with a concentration of 0.1 mol / L was prepared with iron acetylacetonate and acetone, impregnated with potassium sulfate powder, and after removing excess impregnating liquid, the powder was dried. The dried powder is reduced with hydrogen at 400°C to 500°C, washed with water and dried to obtain ferric oxide nanoparticles.

[0030] Example 3: Prepare a solution with a concentration of 0.01 mol / L with iron acetylacetonate and chloroform, impregnate potassium sulfate powder, remove excess impregnating liquid, and dry the powder. The dried powder is reduced with hydrogen at 400°C to 500°C, washed with water and dried to obtain ferric oxide nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com