Method for preparing nickel-loaded halloysite-based methane dry reforming catalyst

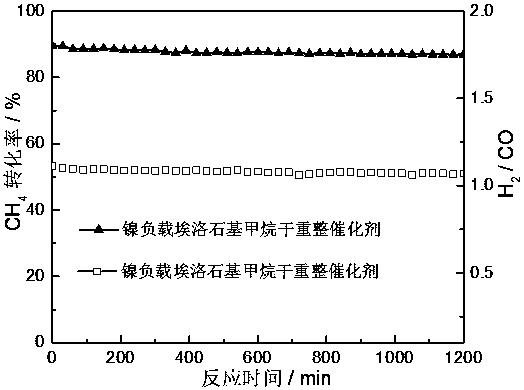

A methane dry reforming and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of low preparation cost and solve serious problems of sintering and carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 4.000g of natural halloysite, 1.200g of sodium carbonate and 20g of sodium nitrate into a nylon ball mill jar, and mill for 60 minutes. Ball-milled halloysite powder is placed in a muffle furnace, with 10 o C / min rate of heating up to 350 o C, calcined for 2 hours, cooled with the furnace, washed with deionized water until the pH value reached 7, and then dried in an oven at 60°C for 12 hours. Get 2g of the above-mentioned pretreated halloysite and add it into a 50ml flask containing a certain amount of deionized water, and stir at room temperature for 30min. Add 0.5613g of nickel nitrate precursor salt into a flask containing 20ml of deionized water to prepare a precursor salt solution, and the loading amount of nickel is 5.5wt%. Then, the prepared precursor salt solution was added into the flask containing halloysite, evaporated with a rotary evaporator for 2 hours, and then dried in an oven at 60° C. for 12 hours to fully dry the catalyst precursor. The prod...

Embodiment 2

[0030] Weigh 4.000g of natural halloysite, 0.800g of sodium carbonate and 20g of sodium nitrate into a nylon ball mill jar, and mill for 60 minutes. Ball-milled halloysite powder is placed in a muffle furnace, with 10 o C / min rate of heating up to 350 o C, calcined for 2 hours, cooled with the furnace, washed with deionized water until the pH value reached 7, and then dried in an oven at 60°C for 12 hours. Get 2g of the above-mentioned pretreated halloysite and add it into a 50ml flask containing a certain amount of deionized water, and stir at room temperature for 30min. 0.5613g of nickel acetate precursor salt was added into a flask containing 20ml of deionized water to prepare a precursor salt solution, and the loading amount of nickel was 5.5wt%. Then, the prepared precursor salt solution was added into the flask containing halloysite, evaporated with a rotary evaporator for 2 hours, and then dried in an oven at 60° C. for 12 hours to fully dry the catalyst precursor. T...

Embodiment 3

[0033] Weigh 4.000g of natural halloysite, 1.200g of sodium carbonate and 20g of sodium nitrate into a nylon ball mill jar, and mill for 60 minutes. Ball-milled halloysite powder is placed in a muffle furnace, with 10 o C / min rate of heating up to 350 o C, calcined for 2 hours, cooled with the furnace, washed with deionized water until the pH value reached 7, and then dried in an oven at 60°C for 12 hours. Get 2g of the above-mentioned pretreated halloysite and add it into a 50ml flask containing a certain amount of deionized water, and stir at room temperature for 30min. Add 0.5613 g of nickel acetylacetonate precursor salt into a flask containing 20 ml of deionized water to prepare a precursor salt solution with a nickel loading of 5.5 wt%. Then, the prepared precursor salt solution was added into the flask containing halloysite, evaporated using a rotary evaporator for 2 hours, and then dried in an oven at 60° C. for 12 hours to fully dry the catalyst precursor. The prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com