Molybdenum-modified molecular sieve-loaded nickel-based methane dry reforming catalyst as well as preparation method and application thereof

A methane dry reforming and nickel catalyst technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex preparation methods, long preparation time, and the catalytic performance of catalysts to be improved, and achieve the goal of preparation The process is simple and the effect of improving the anti-carbon deposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

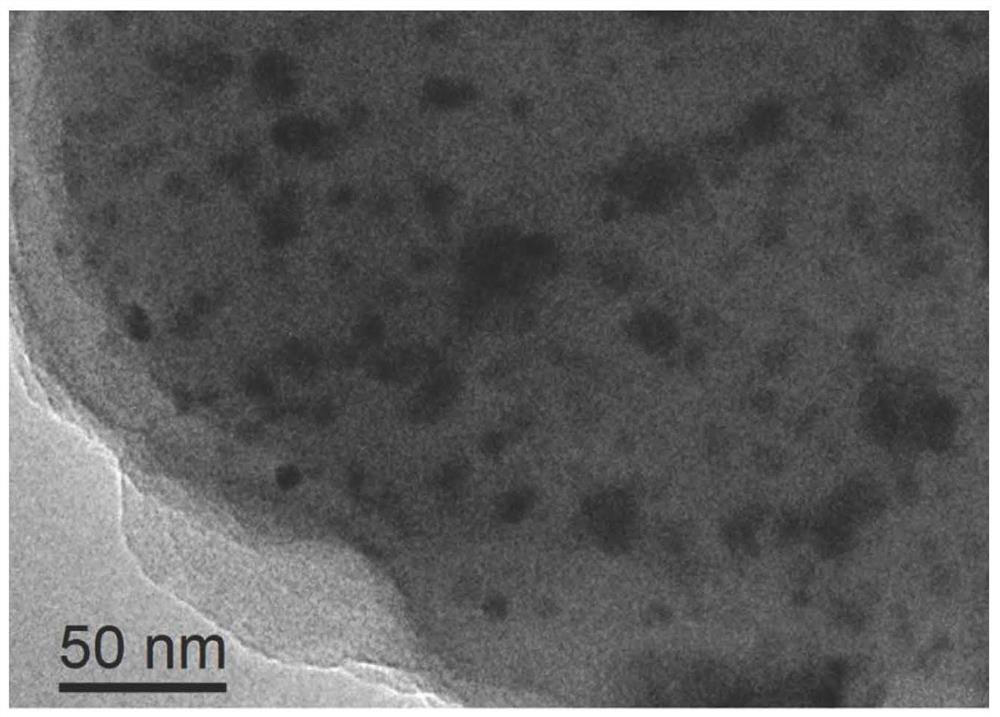

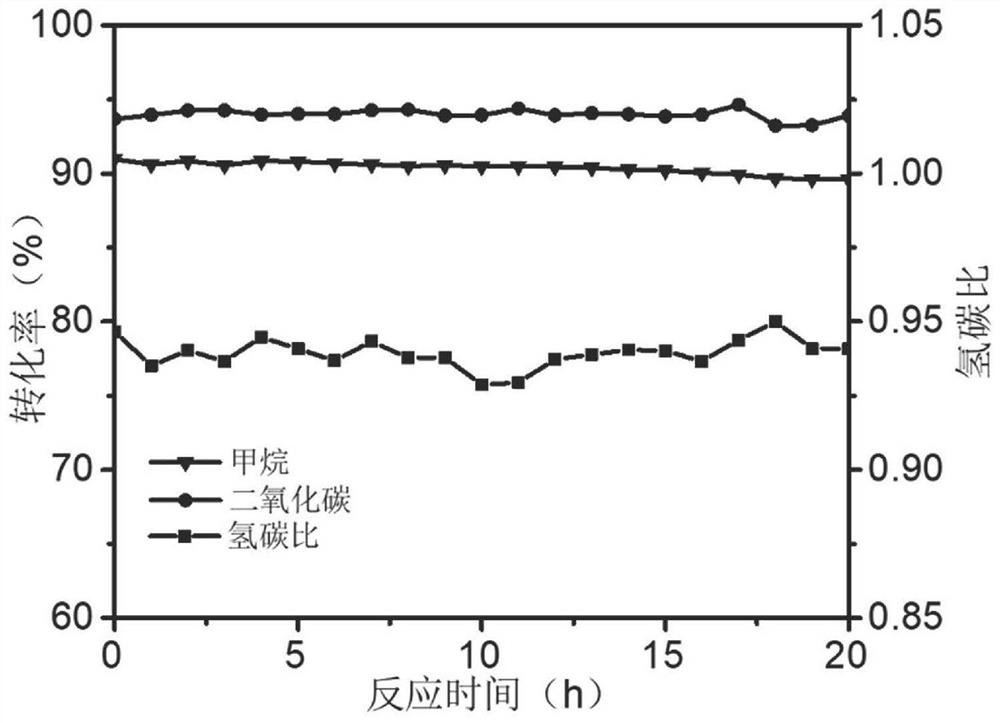

Image

Examples

Embodiment 1

[0025] In this embodiment, a method for preparing a molybdenum-modified molecular sieve-supported nickel-methyl methane dry reforming catalyst has the following process steps:

[0026] a. according to the ratio of the nickel loading of the molybdenum-modified molecular sieve loaded nickel-based methane dry reforming catalyst prepared according to the target to 6wt%, take nickel nitrate and HZSM-5 molecular sieve and disperse them in deionized water, stir vigorously for 8h; then evaporate Remove the solvent and dry at 80°C for 12 hours; then, in an air atmosphere, heat up at a heating rate of 2°C / min, and heat up to 600°C for 4 hours to obtain a powder product A;

[0027] b. the molar ratio of nickel and molybdenum of the molybdenum-modified molecular sieve supported nickel-based methane dry reforming catalyst prepared according to the target is a ratio of 5:1, and the powder product A obtained in step a and ammonium molybdate are dispersed in deionized water, Stir vigorously f...

Embodiment 2

[0035]In this embodiment, a method for preparing a molybdenum-modified molecular sieve-supported nickel-methyl methane dry reforming catalyst has the following process steps:

[0036] a. According to the ratio of the nickel loading of the molybdenum-modified molecular sieve-loaded nickel-methyl methane dry reforming catalyst prepared according to the target to a ratio of 6 wt%, nickel acetylacetonate and HZSM-5 molecular sieve were weighed and dispersed in deionized water, and vigorously stirred for 8 hours; then Evaporate the solvent, dry at 80°C for 12 hours; then raise the temperature at a rate of 2°C / min in an air atmosphere, and heat up to 600°C for 4 hours to obtain a powder product A;

[0037] b. the molar ratio of nickel and molybdenum of the molybdenum-modified molecular sieve supported nickel-based methane dry reforming catalyst prepared according to the target is a ratio of 5:1, and the powder product A obtained in step a and ammonium molybdate are dispersed in deion...

Embodiment 3

[0043] In this embodiment, a method for preparing a molybdenum-modified molecular sieve-supported nickel-methyl methane dry reforming catalyst has the following process steps:

[0044] a. The molybdenum-modified molecular sieve-loaded nickel-based methane dry reforming catalyst prepared according to the target has a nickel loading of 6wt%, weighs nickel acetate and HY molecular sieves and disperses them in deionized water, stirs vigorously for 8 hours; then evaporates the solvent , dried at 80°C for 12 hours; then, in an air atmosphere, the temperature was raised at a rate of 2°C / min, and the temperature was raised to 600°C for 4 hours to obtain a powder product A;

[0045] b. the molar ratio of nickel and molybdenum of the molybdenum-modified molecular sieve supported nickel-based methane dry reforming catalyst prepared according to the target is a ratio of 5:1, and the powder product A obtained in step a and ammonium molybdate are dispersed in deionized water, Stir vigorousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com