Phenolic resin casting plate preparation method

A technology of phenolic resin and casting body, which is applied in the direction of flat products, household utensils, and other household utensils. It can solve the problems of difficult preparation, only focus on vacuuming time, and difficult molding, etc., and achieve the effect of easy molding and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

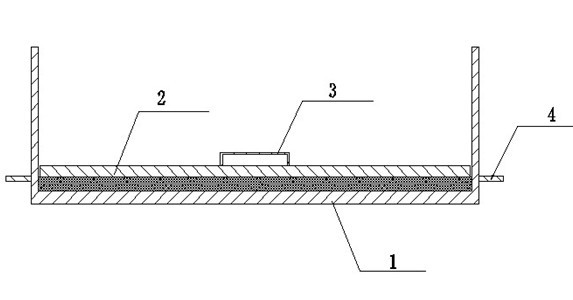

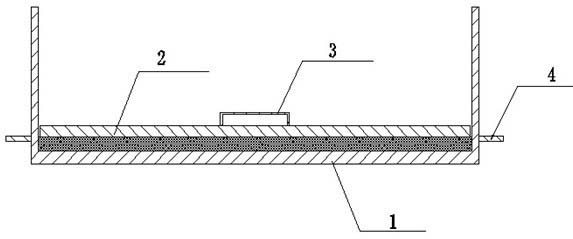

[0025] refer to figure 1 , before preparing the phenolic resin casting body, prepare the mold: clean the flat casting mold 1 (inner cavity size is 300mm×150mm×100mm) and the briquette 2 (outline size is 297mm×147mm×10mm), spray and remove Ready to use after molding agent;

[0026] one. Vacuuming step: Weigh 550g (solid content: 60%) of phenolic resin, pour it into the flat casting mold 1, then put the flat casting mold 1 into a vacuum oven at 50°C, and perform the following operations on the flat casting Mold vacuuming;

[0027] a. When the phenolic resin is pumped until it is about to overflow the flat casting body mold 1, stop vacuuming, but do not release the pressure; after 2 minutes, when the vacuum degree drops, continue to repeat the "vacuumization - stop vacuuming" 6 times (No pressure release)" operation; until the vacuum value drops to 4.0KPa, stop vacuuming, and release the pressure to normal pressure;

[0028] b. Repeat operation a once;

[0029] c. Va...

Embodiment 2

[0034] refer to figure 1 , Before preparing the phenolic resin cast body, prepare the mold: clean the flat plate cast body mold 1 (the inner cavity size is 300mm×150mm×100mm) and the briquette 2 (the outer dimension is 297mm×147mm×10mm), and spray After the release agent is used;

[0035] one. Vacuuming step: Weigh 550g (solid content: 60%) of phenolic resin, pour it into the flat casting mold 1, then put the flat casting mold 1 into a vacuum oven at 60°C, and perform the following operations on the flat casting Mold 1 is vacuumed;

[0036] a. When the phenolic resin is pumped until it is about to overflow the flat casting body mold 1, stop vacuuming, but do not release the pressure; after 5 minutes, when the vacuum degree drops, continue to repeat "vacuumizing - stop vacuuming" 10 times (No pressure release)" operation; until the vacuum value drops to 1.6KPa, stop vacuuming, and release the pressure to normal pressure;

[0037] b. Repeat operation a once;

[0038] ...

Embodiment 3

[0043] Before preparing the phenolic resin cast body, prepare the mold: clean the flat cast body mold 1 (inner cavity size 300mm×150mm×100mm) and briquetting block 2 (outer dimension 297mm×147mm×10mm), spray and demould Ready to use after dose;

[0044] one. Vacuuming step: Weigh 550g (solid content: 60%) of phenolic resin, pour it into the flat casting mold 1, then put the flat casting mold 1 into a vacuum oven at 55°C, and perform the following operations on the flat casting Mold 1 is vacuumed;

[0045] a. When the phenolic resin is pumped until it is about to overflow the flat casting body mold 1, stop vacuuming, but do not release the pressure; after 3.5 minutes, when the vacuum degree drops, continue to repeat the "vacuumization - stop pumping" 10 times Vacuum (no pressure release)" operation; until the vacuum value drops to 2.8KPa, stop vacuuming and release the pressure to normal pressure;

[0046] b. Repeat operation a once;

[0047] c. Vacuum until the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com