Chemical regeneration method in casting waste sand disposing process

A technology of chemical regeneration and casting waste sand, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, manufacturing tools, etc. It can solve the problems that impurities cannot be completely removed, and achieve improved chemical resistance to sand sticking and good economy. Good performance and good overall effect of waste sand regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

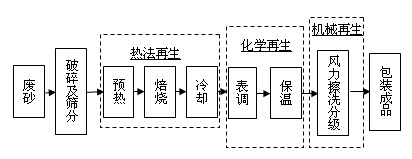

[0039] Embodiment one (see figure 1 ):

[0040] 1. Crushing and screening waste sand:

[0041] Batches of resin with particle sizes ranging from 20 / 40, 40 / 20, 30 / 50, 50 / 30, 40 / 70, 70 / 40, 50 / 100, 100 / 50, 70 / 140, 140 / 70, 100 / 200 After the waste sand or green mold sand is unloaded, it is processed by a vibrating crusher, and unbroken metal blocks (such as iron blocks, aluminum blocks, etc.) are removed from the screen surface after passing through a 4-mesh screen.

[0042] 2. Thermal regeneration:

[0043] The waste sand from which large aggregates and sundries have been removed is fed into the vertical two-stage waste sand roaster from the sand adding device at the top of the roaster, and the waste sand is fully preheated by being heated by the flue gas heat exchange system in the roaster , After roasting at 600-700°C, release the sand out of the furnace with a sand output of 5 tons per hour, and cool it by air in a fluidized fluidized bed, take a sand sample to measure the P...

Embodiment 2

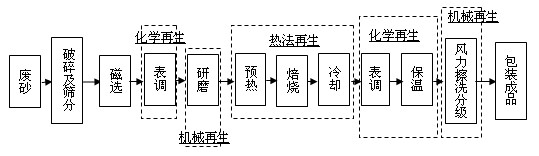

[0047] Embodiment two (see figure 2 ):

[0048] 1. Crushing and screening waste sand:

[0049] Each batch of spent sand should have the same range of particle size values (ie 40 / 70, 50 / 100, 70 / 140, etc.). The waste sand of the same batch passes through the crushing equipment to make the large waste sand pellets into small pieces, and then uses a vibrating screening machine with a screen of not less than 4 mesh (such as 8 mesh, 10 mesh, etc.) Unbroken metal pieces (such as iron pieces, aluminum pieces, etc.) are removed from the screen surface. The waste sand particles pass through the magnetic separation channel of the magnetic separator to further attract and remove the smaller granular or powdery metallic iron and its oxides that have not been removed during the screening process.

[0050] 2. Chemical and mechanical regeneration:

[0051] Put the cast alkali phenolic resin or green mold sand waste sand after iron removal into a stirrer with a mechanical stirring mecha...

Embodiment 3

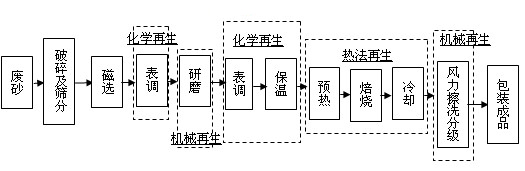

[0060] Embodiment three (see image 3 ):

[0061]The alkali phenolic resin waste sand of the foundry factory A after being processed by the first step in the embodiment 1, after removing the magnetic metal impurities in the waste sand by a 4000 gauss conveyor belt type cylinder iron removal device, the waste sand is placed at room temperature Under the condition of 10-40℃, the surface conditioning solution I is used for surface chemical treatment. The surface conditioning solution is composed of industrial phosphoric acid and industrial hydrochloric acid in a mass ratio of 1-20:1-80 to form an aqueous solution with a molar concentration of 0.01-1mol / L. One side of the curtain-like sand flow falling from the sand outlet of the cylindrical sand bucket is sprayed on the surface of the sand curtain, and the meter is adjusted by 5-15 liters per second. The treated recycled sand enters the silo for storage for 1-24 hours for mechanical grinding. Grind in the grinding equipment for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com