Thermosetting shape-memory resin capable of memorizing multiple shapes, and preparation method thereof

A thermosetting and memory technology, applied in the application field of shape memory functionalization of high-performance resin-based composite materials, it can solve the problems of limited application scope and inability to achieve multi-stage deformation, and achieve high mechanical properties, high mechanical properties and temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

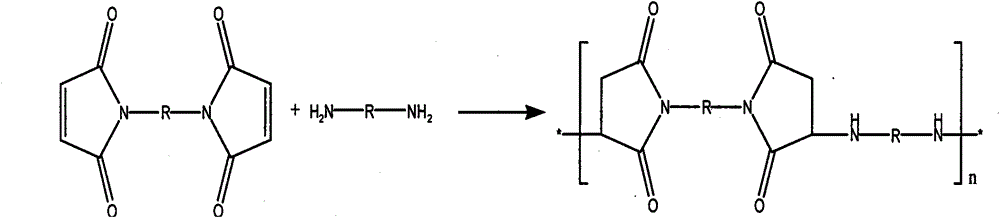

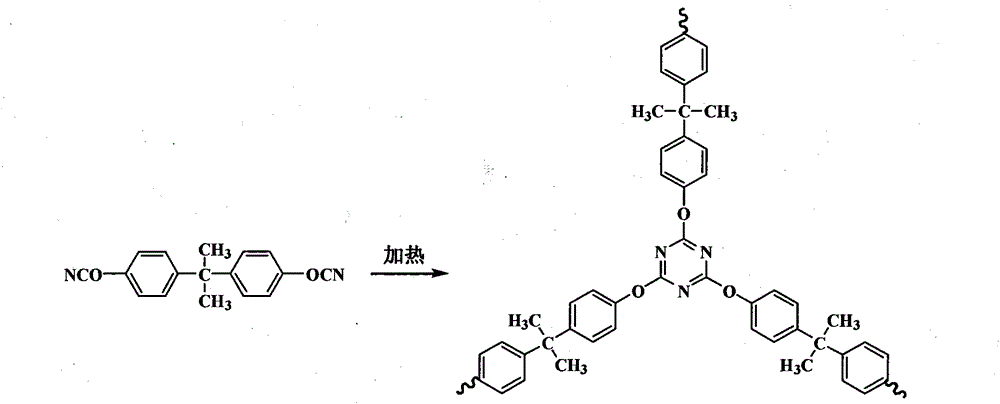

Method used

Image

Examples

Embodiment 1

[0021] In a three-necked flask equipped with mechanical stirring and a thermometer, add 1 mole of 4,4'bismaleimidodiphenylmethane and 0.5 mole of polyetheramine D400 into an appropriate amount of tetrahydrofuran, so that the polymer mass accounts for 20% of the total system mass. %, that is, the mass ratio of the total mass of bismaleimide and polyetheramine to tetrahydrofuran is 1:4, then stir and start heating to 65°C. After 24 hours of reaction, a homogeneous amber solution formed. Then the solution was cooled to room temperature, 0.5 mole of bisphenol A cyanate was added, and the stirring was accelerated until the bisphenol A cyanate was completely dissolved. The mixed solution is poured into a mold with a flat surface, placed in a vacuum oven, and vacuumed to remove air bubbles. After 5 minutes, the mold was taken out from the vacuum oven, and placed at room temperature to evaporate excess solvent in the solution. After 24 hours, put the mold in the oven, and make the r...

Embodiment 2

[0023] Add 1 mole of 4,4'bismaleimidodiphenylmethane and 1 mole of polyetheramine D400 into tetrahydrofuran in a three-necked flask equipped with mechanical stirring and a thermometer, so that the polymer mass accounts for 20% of the total system mass , then stir and begin heating to 65°C. After 24 hours of reaction, a homogeneous amber solution formed. Then the solution was cooled to room temperature, 1 mole of bisphenol A cyanate was added, and the stirring was accelerated until the bisphenol A cyanate was completely dissolved. The mixed solution is poured into a mold with a flat surface, placed in a vacuum oven, and vacuumed to remove air bubbles. After 5 minutes, the mold was taken out from the vacuum oven, and placed at room temperature to evaporate excess solvent in the solution. After 24 hours, put the mold in the oven, and make the resin fully react according to the curing conditions of 120°C / 0.5h, 150°C / 1h, 180°C / 1h, and 200°C / 2h. After the reaction is over, the ma...

Embodiment 3

[0025] Add 1 mole of 4,4'bismaleimidodiphenylmethane and 2 moles of polyetheramine D400 into tetrahydrofuran in a three-necked flask equipped with mechanical stirring and a thermometer, so that the polymer mass accounts for 20% of the total system mass , then stir and begin heating to 65°C. After 24 hours of reaction, a homogeneous amber solution formed. Then the solution was cooled to room temperature, 2 moles of bisphenol A cyanate was added, and the stirring was accelerated until the bisphenol A cyanate was completely dissolved. The mixed solution is poured into a mold with a flat surface, placed in a vacuum oven, and vacuumed to remove air bubbles. After 5 minutes, the mold was taken out from the vacuum oven, and placed at room temperature to evaporate excess solvent in the solution. After 24 hours, put the mold in the oven, and make the resin fully react according to the curing conditions of 120°C / 0.5h, 150°C / 1h, 180°C / 1h, and 200°C / 2h. After the reaction is over, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com