An order-disorder phase transition-based shape memory method for semiconductor materials

A technology of semiconductors and ordered phases, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve problems that limit the application of shape memory materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the shape memory effect of nanowire section sample:

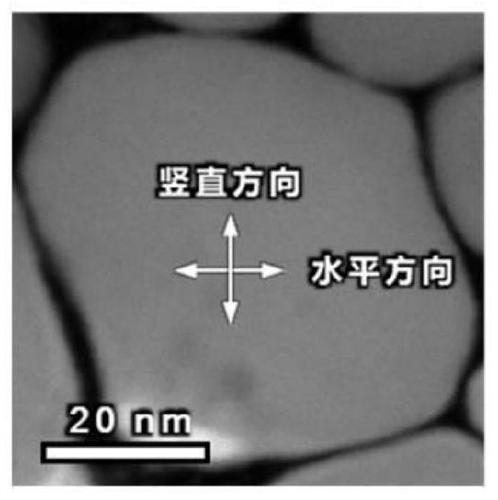

[0035] The first step is to prepare Ag by using focused ion beam micro-nano processing instrument 2 S nanowire cross-section sample and transferred to the heating chip, as figure 2 shown.

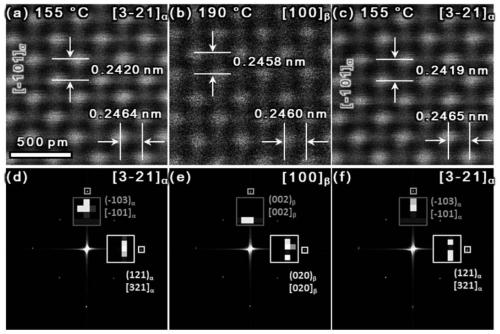

[0036] In the second step, the sample is heated to 10-20°C below the phase transition point of the sample (due to the nanoscale Ag 2 The α-β phase transition point of S decreases as its size decreases. At the same time, considering the convenience of rapid temperature rise across its phase transition point, the low-temperature phase holding temperature is usually 130-160 ° C. The preferred temperature for nanomaterials with a size of 45 nm is 155°C).

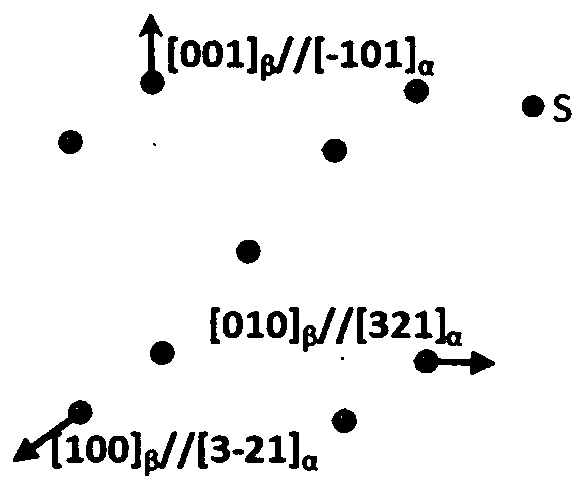

[0037] In the third step, the sample is rapidly heated until the phase transition is completed and becomes the BCC phase (due to the nanoscale Ag 2 The β-α phase transition point of S decreases as its size decreases. At the same time, considering the convenience o...

Embodiment 2

[0041] Embodiment 2: Shape regulation of nanowire cross section sample:

[0042] The first step is to prepare Ag by using focused ion beam micro-nano processing instrument 2 S nanowire cross-section samples and transferred to a heated chip.

[0043] In the second step, the sample is heated to 10-20°C lower than the phase transition point of the sample.

[0044] In the third step, the sample is rapidly heated until the phase changes to the BCC phase. Samples along [-101] α The direction is elongated by 1%-2%, and the shape changes.

[0045] The fourth step is to keep warm for more than 30 minutes. At this point the residual order is already at the noise level.

[0046] In the fifth step, the temperature is lowered so that the sample turns back to the monoclinic phase. At this time, the sample will no longer have the shape of the initial low-temperature phase, and the [-101] of the sample α The directions will be distributed in three equivalent directions with certain pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com