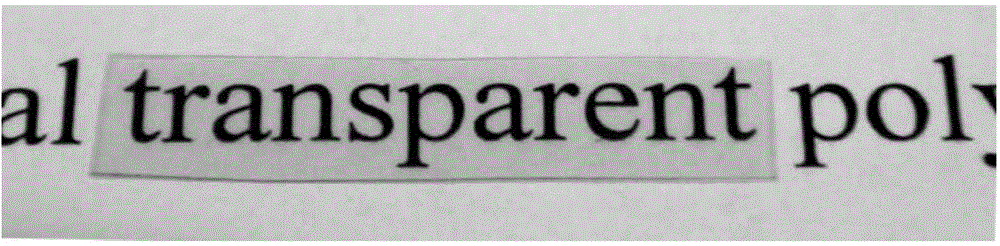

Optical transparent light-colored high temperature-resisting shape memory polymer and preparation method thereof

A memory polymer and optically transparent technology, applied in the field of light-colored polymers and their preparation, can solve the problems of low thickness and low phase transition temperature of transparent polyimide, and achieve excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

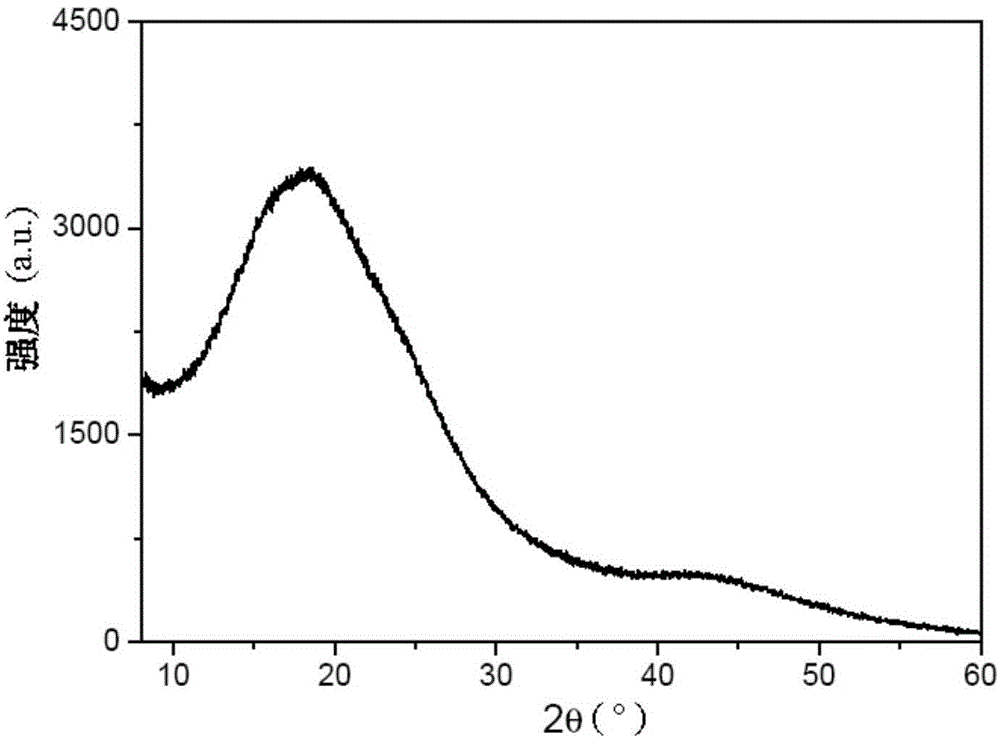

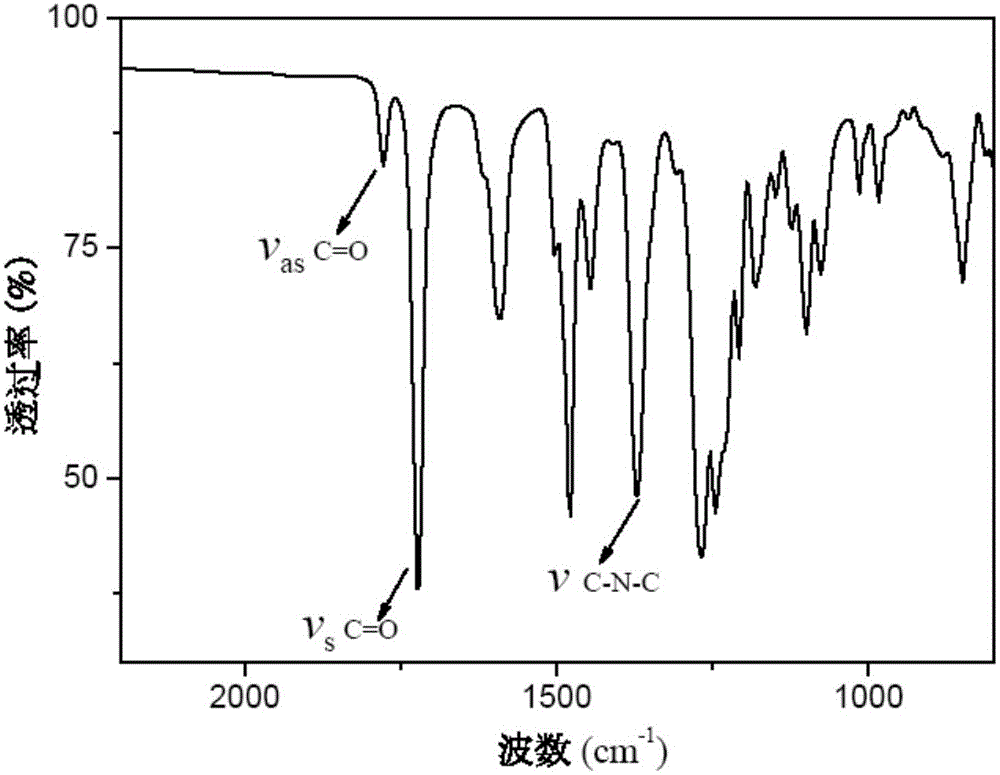

[0047] Specific Embodiment 1: This embodiment is an optically transparent light-colored high-temperature-resistant shape-memory polymer that uses 1,3-bis(3-aminophenoxy)benzene and bisphenol A diether dianhydride as reactive monomers Prepared; the molar ratio of 1,3-bis(3-aminophenoxy)benzene to bisphenol A diether dianhydride is (0.9-1.1):1.

[0048] The advantage of this implementation mode:

[0049] 1. Phase transition temperature T of the optically transparent light-colored heat-resistant shape memory polymer prepared in this embodiment g It is 168°C-177°C. Compared with the phase transition temperature of the optically transparent light-colored shape memory polymer reported in the literature at 63°C, its phase transition temperature T g Increased by 105℃~114℃, it can be applied to optoelectronic devices at high temperature;

[0050] 2. The optically transparent light-colored high-temperature-resistant shape-memory polymer prepared in this embodiment can still have a goo...

specific Embodiment approach 2

[0054] Embodiment 2: The difference between this embodiment and Embodiment 1 is that it is characterized in that the structural formula of an optically transparent light-colored high-temperature-resistant shape memory polymer is:

[0055]

[0056] Wherein, the range of n is 20-85, and n is an integer. Others are the same as the first embodiment.

specific Embodiment approach 3

[0057] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the number average molecular weight of the optically transparent light-colored heat-resistant shape memory polymer is 20.1kg / mol~52.2kg / mol . Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com