Fabric with bidirectional temperature adjusting performance and preparation method thereof

A temperature-regulating and fabric technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of high phase transition temperature, unidirectional temperature-regulating fabrics that cannot resist cold and heat, and cannot meet the requirements of phase transition temperature and Improvement of thermoregulation performance, improvement of thermal activity, and improvement of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

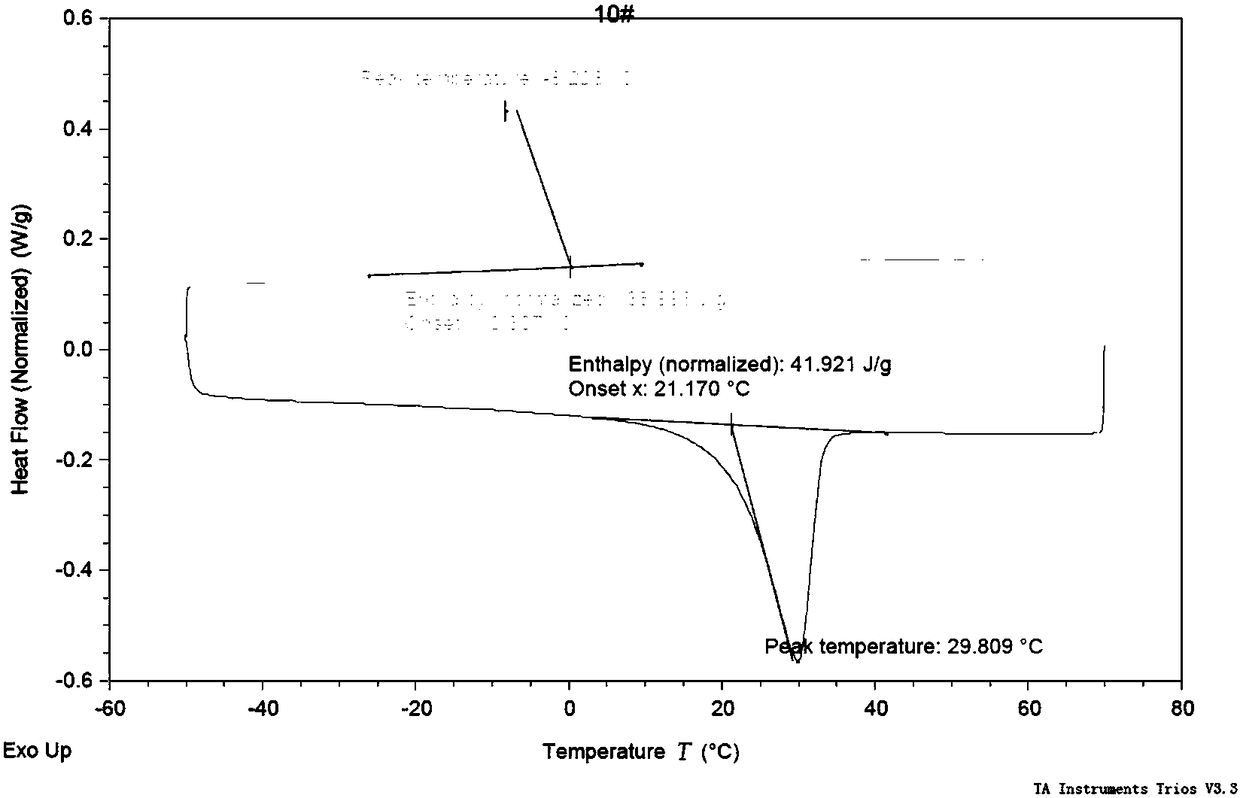

Embodiment 1

[0033] A method for preparing a bidirectional temperature-regulating performance fabric, comprising the following steps:

[0034] (1) Mix the PEG compound, 2D resin and catalyst, and stir evenly to obtain a temperature-regulating working fluid; wherein, the mass fractions of each component in the temperature-regulating working fluid are as follows: the mass fraction of the PEG complex is 50%; The massfraction of agent is 23.5%; The massfraction of catalyst is 3.6%; The massfraction of water is 22.9%;

[0035] Wherein, the preparation process of PEG compound is:

[0036] Melt PEG-1000 at 65°C, then add PEG-600 to it, stir and mix evenly to obtain a PEG complex; wherein, the molar ratio of PEG-600 and PEG-1000 is 0.1:0.9;

[0037] The catalyst is MgCl in a weight ratio of 5:1 2 ·6H 2 A mixture of O and citric acid;

[0038] (2) Adopt the method of two immersion and two tying, mix and dye the temperature-adjusting working solution and the fiber fabric at a ratio of 1:1 to the...

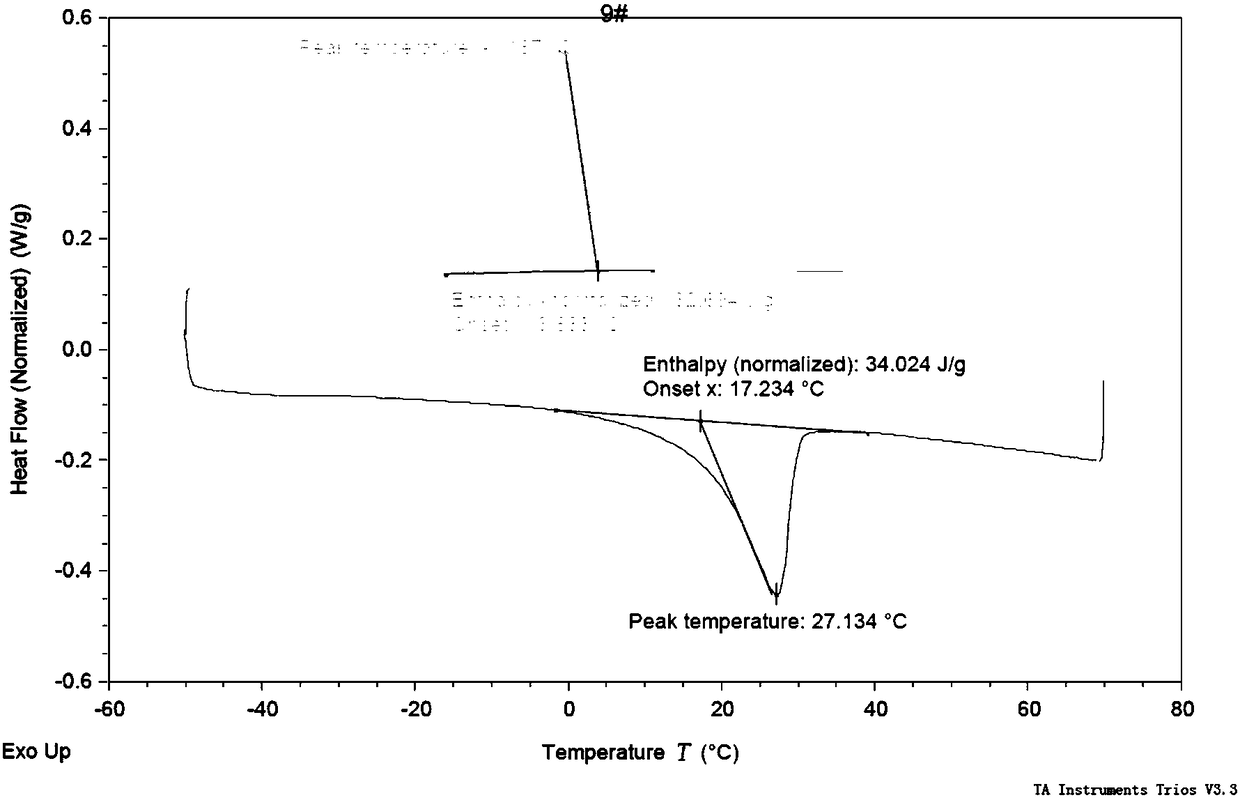

Embodiment 2

[0041] A method for preparing a bidirectional temperature-regulating performance fabric, comprising the following steps:

[0042] (1) Mix the PEG complex, 2D resin, and catalyst, and stir evenly to obtain a temperature-regulating working fluid; wherein, the mass fractions of each component in the temperature-regulating working fluid are as follows: the mass fraction of the PEG complex is 55%; The massfraction of agent is 20%; The massfraction of catalyst is 1.5%; The massfraction of water is 23.5%;

[0043] Wherein, the preparation process of PEG compound is:

[0044] Melt PEG-1000 at 65°C, then add PEG-600 to it, stir and mix evenly to obtain a PEG compound; wherein, the molar ratio of PEG-600 and PEG-1000 is 0.2:0.8;

[0045] The catalyst is MgCl in a weight ratio of 3:1 2 ·6H 2 A mixture of O and citric acid;

[0046] (2) Adopt the method of two immersion and two tying, mix and dye the temperature-adjusting working solution and the fiber fabric at a ratio of 0.5:0.8 to ...

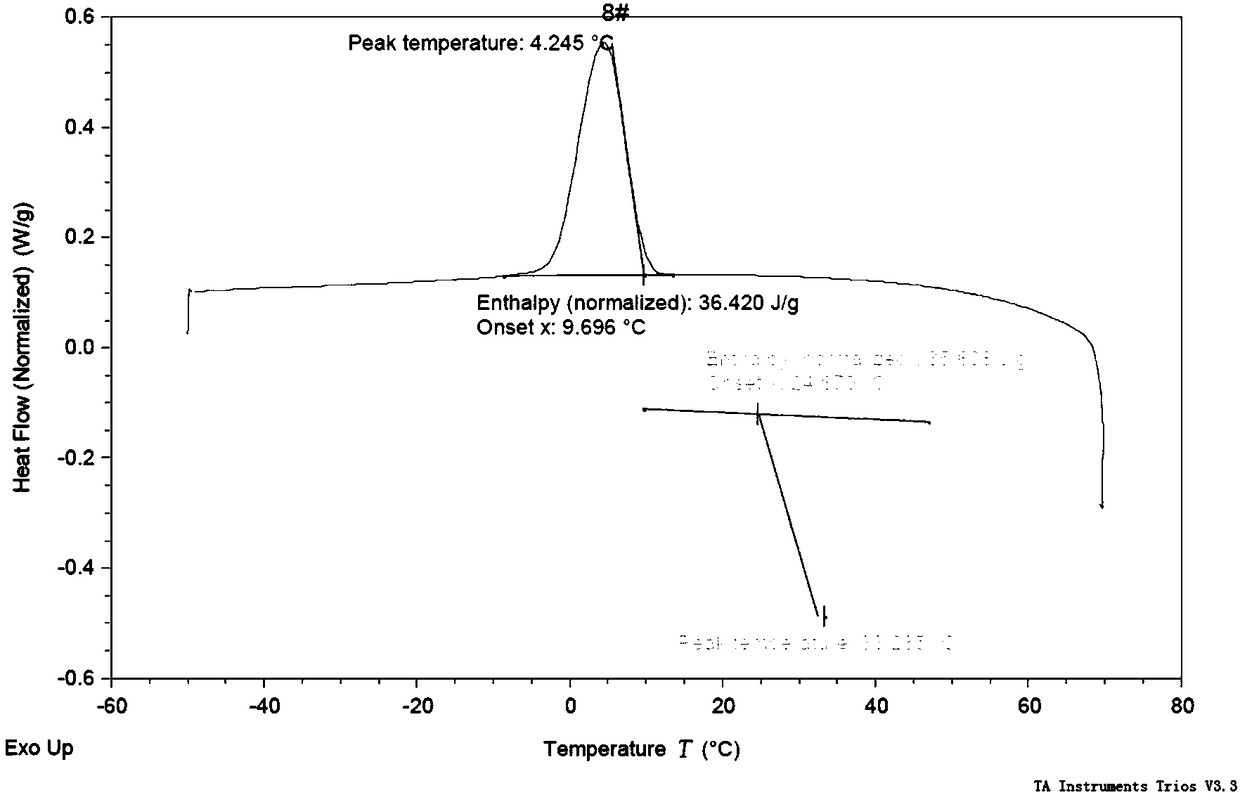

Embodiment 3

[0049] A method for preparing a bidirectional temperature-regulating performance fabric, comprising the following steps:

[0050] (1) Mix the PEG complex, 2D resin and catalyst, and stir evenly to obtain a temperature-regulating working fluid; wherein, the mass fractions of each component in the temperature-regulating working fluid are as follows: the mass fraction of the PEG complex is 52%; The massfraction of agent is 22%; The massfraction of catalyst is 4%; The massfraction of water is 22%;

[0051] Wherein, the preparation process of PEG compound is:

[0052] Melt PEG-1000 at 65°C, then add PEG-600 to it, stir and mix evenly to obtain a PEG complex; wherein, the molar ratio of PEG-600 and PEG-1000 is 0.3:0.7;

[0053] The catalyst is MgCl in a weight ratio of 5:12 ·6H 2 A mixture of O and citric acid;

[0054] (2) Adopt the method of two immersion and two tying, mix and dye the temperature-adjusting working solution and the fiber fabric at a ratio of 1:1 to the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com