Liquid crystal monomer bicyclohexyl-containing epoxyethane compound and synthetic method thereof

A technology of cyclohexaneoxane and liquid crystal monomers, applied in chemical instruments and methods, liquid crystal materials, organic chemistry, etc., can solve problems such as low rotational viscosity, and achieve the goal of reducing viscosity, improving phase transition temperature, and reducing threshold voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

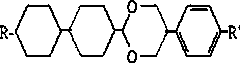

[0016] Embodiment 1, a liquid crystal monomer containing bicyclohexane oxane compound, is characterized in that the structure of the compound is as follows:

[0017]

[0018] In the formula, R is one of fluorine, chlorine, H, C1-C5 straight-chain alkyl, C1-C5 straight-chain alkoxy, and R' is fluorine, chlorine, H, C1-C5 straight-chain alkyl, C1 -One of C5 straight-chain alkoxy groups and cyano groups. This type of compound can be used alone or in combination for liquid crystal display in various display forms. The following synthesis route is adopted:

[0019]

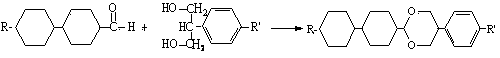

[0020] I II III

[0021] Using p-alkylbicyclohexylcarbaldehyde shown in structure I and 2-p-alkylphenylpropanediol shown in II as raw materials, wherein R, R' in compounds I and II are combined with bicyclohexane oxane compounds R and R' in III are the same, using p-toluenesulfonic acid as a catalyst, using an organic solvent as a reaction medium, and reacting for 2-12 hours at a temperature of 35-...

Embodiment 2

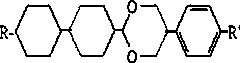

[0024] Example 2, a liquid crystal monomer containing bicyclohexane oxane compound and its synthesis method. The bicyclohexane oxane compound in this example is 5-p-ethylphenyl-2-(p-propylbicyclohexyl Alkyl)-1,3-dioxane, represented by IIIb;

[0025] Add 29 g of p-n-pentyl bicyclohexyl formaldehyde, 22 g of 2-p-ethylphenylpropanediol, 4 g of catalyst p-toluenesulfonic acid, and 110 mL of toluene into a 250 mL three-necked reaction flask equipped with a mechanical stirrer, a reflux condenser, and an addition funnel. Stir and heat, reflux at 108-110°C for 3-8 hours, other conditions are the same as in Example 1, and purify to obtain 33g of product IIIb, ωⅢb: 99.5%, yield: 70.5%, product mass spectrometry result: ES-MS m / z: 426[ M]+.

[0026] The present invention selects bicyclohexane and oxane as the molecular skeleton, designs liquid crystal compound III containing bicyclohexane oxane, and is shown in I with p-alkylbicyclohexyl formaldehyde structure, and 2-p-alkylphenylpropa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com