Inorganic phase change energy storage particles, floor heating mortar and preparation method thereof

A technology of inorganic phase change and inorganic phase change materials, which is applied in the field of floor heating mortar and its preparation, and inorganic phase change energy storage particles, can solve the problems of building material performance change, wall damage, phase separation, etc. The effect of preventing loss, avoiding flow and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An inorganic phase change energy storage particles, formulation of floor heating mortar, including the following steps:

[0046] 1, preparation of phosphate methyl starch gum:

[0047] A. The mass percentage of the esterified starch gum comprises: 1.3% sodium dihydrogen phosphate, 9.0% starch, 79.3% of water (including 72.3% in the first step in the formulation). ); 10.4% aqueous NaOH aqueous NaOH (including 1 ‰ in the first step in the formulation) and 10.3% in the first step of the formulation)

[0048] B, formulation:

[0049] The first step: esterification synthesis: After adding water in dihydrogen phosphate, stirred and dissolved, the pH is adjusted with a NaOH aqueous NaOH in a mass percentage concentration of 20%, adding starch, thoroughly stirring dispersion to form a starch, at 65 The reaction was heated under ° C for 20 min to obtain an esterified starch mixed pulp;

[0050] Step 2: Wash of esterification starch: Stay in the esterified starch mixed pulp for more ...

Embodiment 2~8

[0064] Mainly for the preparation of inorganic phase change energy storage particles, the amount of sodium sulfate, gypsum, and cement, water-absorbing resin, phosphate starch gel and water are fixed.

[0065] 1, preparation of phosphate methyl starch gum:

[0066] A. The mass percent composition of the phosphate methyl starch gel is consistent with Example 1;

[0067] B. The formulation of the phosphate formulated starch is consistent with Example 1;

[0068] 2, the preparation of inorganic phase change storage particles:

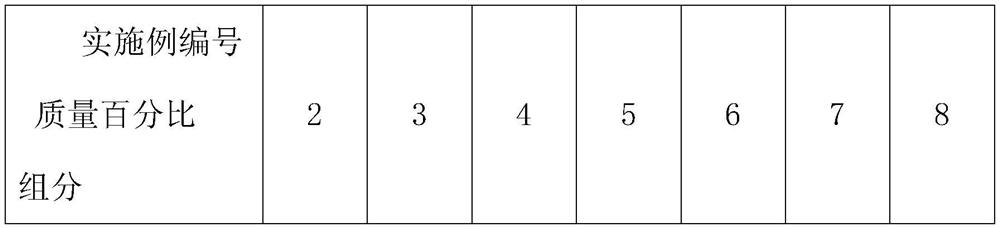

[0069] a, the composition and mass percentage of ingredients in each embodiment are shown in Table 1;

[0070] B, mix, granulation and cover:

[0071]Tenhydrous sodium sulfate is mixed with water, stir the sodium sodium sulfate to dissolve, add phosphate amyloid gum, stirred and dispersion, add a water absorbing resin, and then add gypsum, stirred and uniform. After formulating a paste mixture, the formulation of the prepared paste mixture was carried out by d...

Embodiment 9~14

[0081] Mainly for the preparation of inorganic phase change energy storage particles, water, water absorbing resin, phosphate starch, gypsum, and cement and other amounts are changed, and the amount of sodium sodium sulfate is fixed.

[0082] 1, preparation of phosphate methyl starch gum:

[0083] A. The mass percent composition of the phosphate methyl starch gel is consistent with Example 1;

[0084] b, formulation: The phosphate starch formulation is consistent with Example 1;

[0085] 2, the preparation of inorganic phase change storage particles:

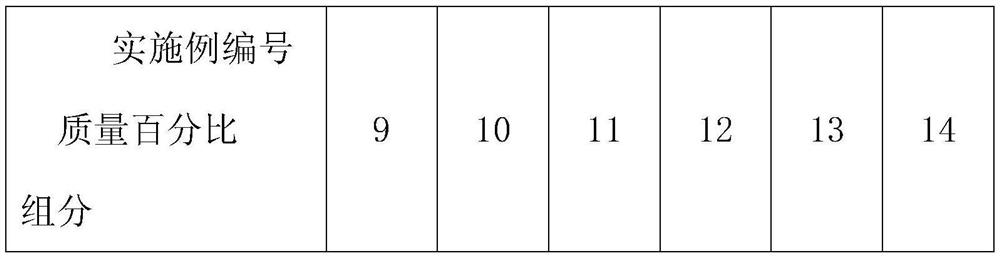

[0086] a, the composition and mass percentage of ingredients in each embodiment are shown in Table 2;

[0087] B, mix, granulation, and coating: consistent with Example 1;

[0088] Table 2: Components and mass percentages in each embodiment:

[0089]

[0090]

[0091] C, envelope:

[0092] Its envelope process is consistent with Example 1;

[0093] 3, floor heating mortar (or: inorganic phase change storage particle floor heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com