High-toughness and low-viscosity benzoxazine/diallyl diphenol/bismaleimide blended resin and preparation method thereof

A technology of bismaleimide and diallyl diphenol, applied in the field of benzoxazine/diallyl diphenol/bismaleimide blend resin and its preparation, to improve processing flow properties, improved heat resistance, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

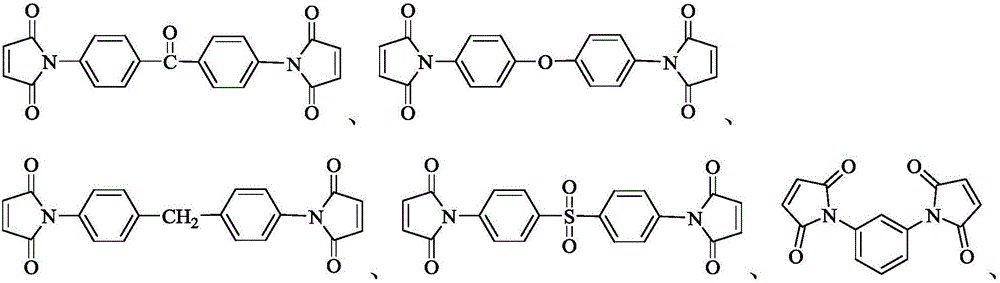

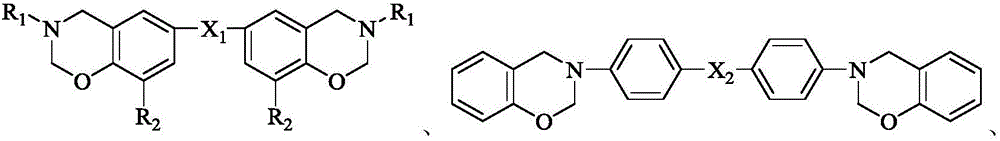

Method used

Image

Examples

Embodiment 1

[0040] Weigh 0.87 mol of diallyl biphenol (DABP) and stir in a three-necked flask. When the temperature rises to about 125°C, add 1 mol of N,N'-4,4'-diphenylmethane bismaleoyl imine (BDM), stir until BDM and DABP are evenly mixed, add 1mol diphenylmethane diamine type benzoxazine (BOZ), and continue to stir for 30 minutes, pour the blend into a mold while it is hot, and put Put it into a vacuum oven at 115° C. for vacuum defoaming for about 4 hours to obtain a blended resin cast body. Then transfer the mold to a temperature-programmed oven for curing. The curing temperature and time are 130°C / 2 hours+150°C / 2 hours+170°C / 2 hours+190°C / 2 hours+200°C / 6 hours. Cool to room temperature to obtain a solidified sample.

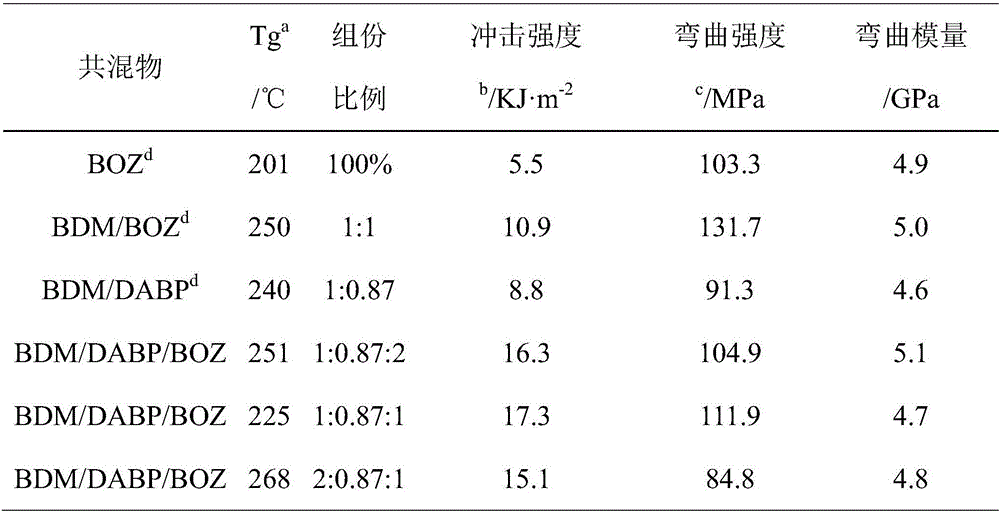

[0041] According to the GB / T 1843-2008 standard, the average value of the unnotched impact strength of the sample is 17.3KJ m -2 , the specific performance data are shown in Table 1.

Embodiment 2

[0043] Weigh 0.87 mol of diallyl biphenol (DABP) and stir in a three-necked flask. When the temperature rises to about 120°C, add 2 mol of N,N'-4,4'-diphenylmethane bismaleoyl imine (BDM), stir until BDM and DABP are evenly mixed, add 1mol diphenylmethane diamine type benzoxazine (BOZ), and continue to stir for 50 minutes, pour the blend into a mold while it is hot, and put Put it into a vacuum oven at 120° C. for vacuum defoaming for about 4 hours to obtain a blended resin cast body. Then transfer the mold to a temperature-programmed oven for curing. The curing temperature and time are 130°C / 2 hours+150°C / 2 hours+170°C / 2 hours+190°C / 2 hours+200°C / 6 hours. Cool to room temperature to obtain a solidified sample.

[0044] According to the GB / T 1843-2008 standard, the average value of the unnotched impact strength of the sample is 15.1KJ m -2 , the specific performance data are shown in Table 1.

Embodiment 3

[0046] Weigh 0.87 mol of diallyl biphenol (DABP) and stir in a three-necked flask. When the temperature rises to about 125°C, add 1 mol of N,N'-4,4'-diphenylmethane bismaleoyl imine (BDM), stir until BDM and DABP are evenly mixed, add 2mol diphenylmethane diamine type benzoxazine (BOZ), and continue to stir for 40 minutes, pour the blend into a mold while it is hot, and put Put it into a vacuum oven at 120° C. for vacuum defoaming for about 4 hours to obtain a blended resin cast body. Then transfer the mold to a temperature-programmed oven for curing. The curing temperature and time are 130°C / 2 hours+150°C / 2 hours+170°C / 2 hours+190°C / 2 hours+200°C / 6 hours. Cool to room temperature to obtain a solidified sample.

[0047] According to the GB / T 1843-2008 standard, the average value of the unnotched impact strength of the sample is 16.3KJ m -2 , the specific performance data are shown in Table 1.

[0048] Table 1 lists the bismaleimide (BDM) blended resin curing specimens witho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com