Resin casting coil dry-type transformer structure and assembling method thereof

A dry-type transformer, resin casting technology, applied in the field of transformers, can solve the problems of insufficient magnetic cross-section, short creepage path, poor strength, etc., and achieve the effects of reducing partial discharge, increasing creepage distance, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

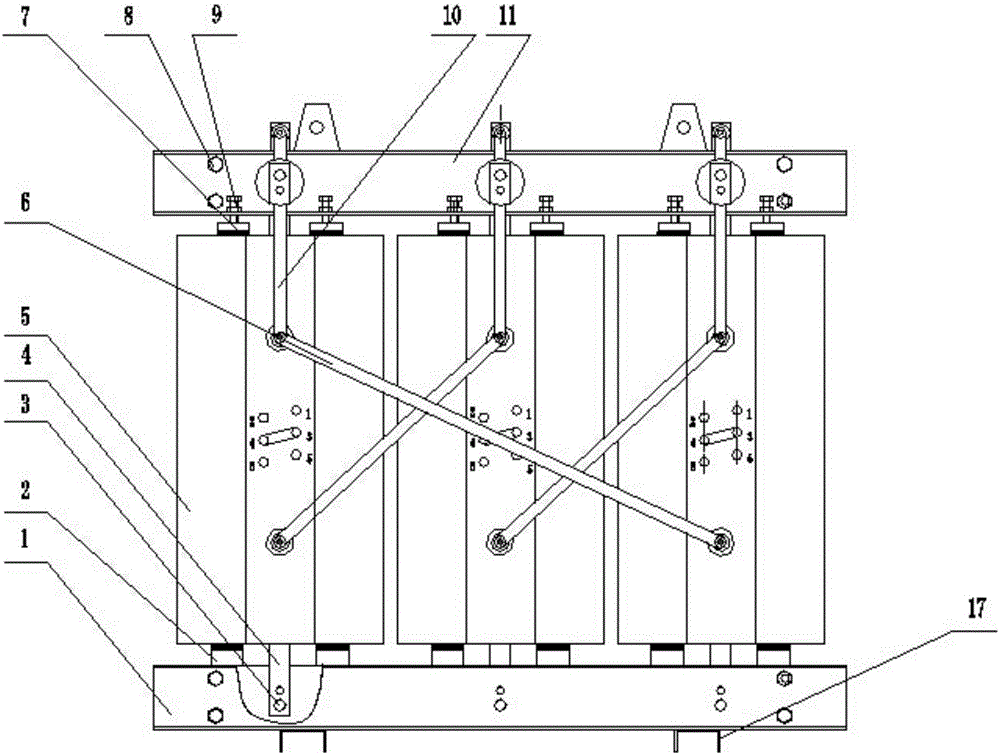

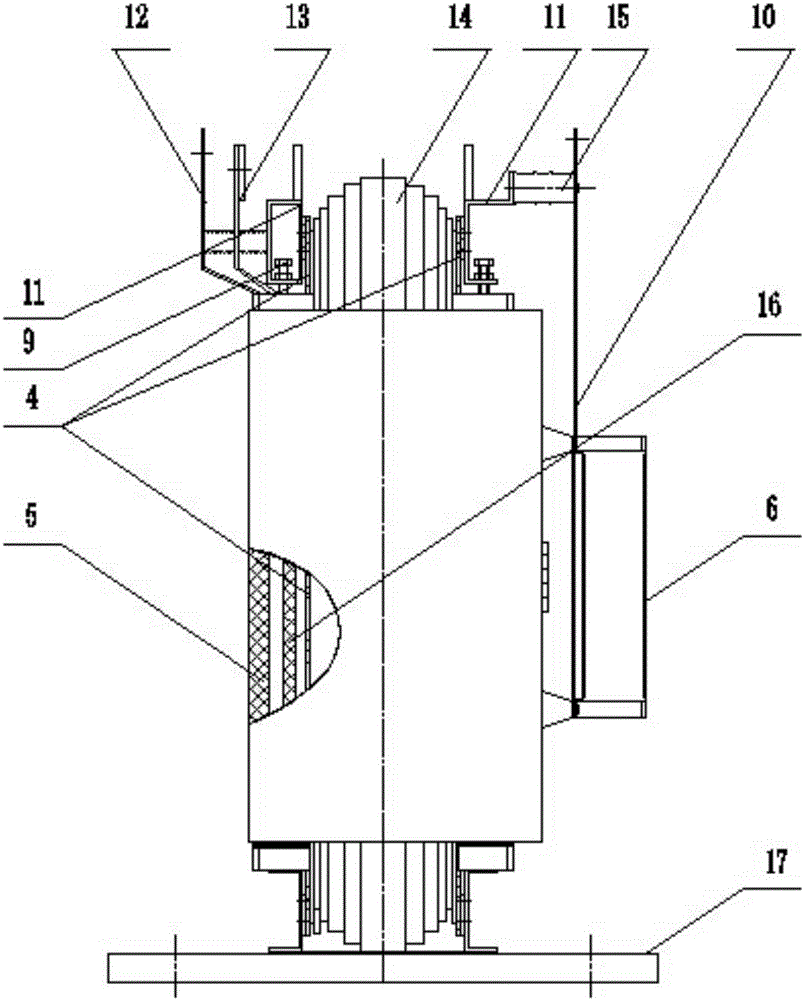

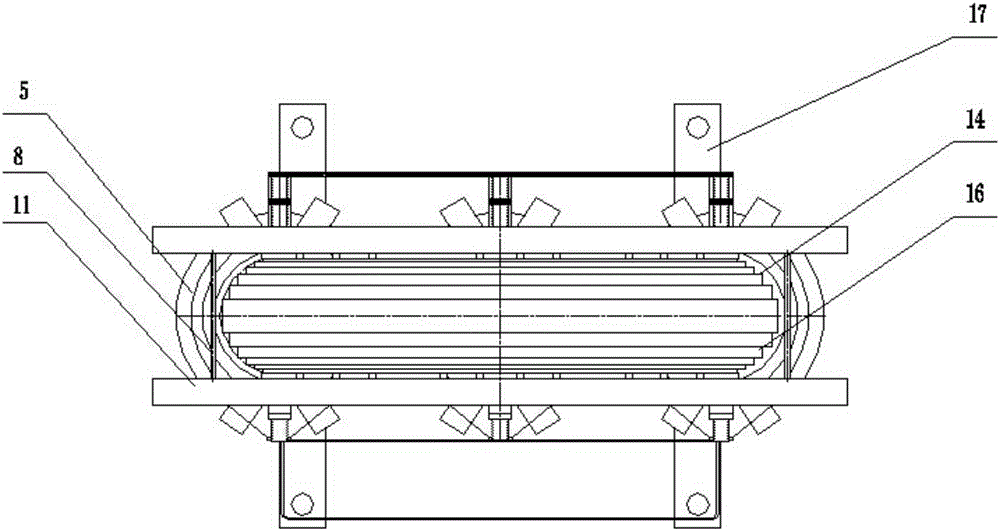

[0041] like Figure 1 to Figure 12 As shown, a resin casting coil dry-type transformer structure includes a transformer body arranged on a base, the base is a supporting channel steel 17, and the transformer body includes an iron core 14, an upper clamp 11, a lower clamp 1, a low-voltage resin coil 16 and the high-voltage resin coil 5. The iron core 14 includes an iron core column, an upper magnetic yoke and a lower magnetic yoke. The iron core 14 is provided with three iron core columns, and the outer circumference of the iron core column is respectively vertically fitted with a high-voltage resin coil 5 and a low-voltage resin coil 16; The bottoms of the high-voltage resin coil 5 and the low-voltage resin coil 16 are seated on the lower clamp 1 through the cushion block and the insert 2, and the tops of the high-voltage resin coil 5 and the low-voltage resin coil 16 are connected to the The upper clamping part is pressed against the pressing plate 18 by the pressing nail 9 o...

Embodiment 2

[0048] A resin casting coil dry-type transformer structure, the structure is as described in Embodiment 1, the difference is that: the upper surface of the pressure plate 18 is provided with a cylindrical pin 1801, the top of the cylindrical pin 1801 is hemispherical, and the bottom end of the pressure nail 9 is set There are blind holes to accommodate cylindrical pins, and the blind ends of the blind holes are also hemispherical. The pressing plate 18 and the pressing nail 9 are connected through a cylindrical pin and a blind hole, and the cylindrical pin is inserted into the blind hole to ensure the stability of the connection between the pressing plate and the pressing nail.

[0049] like Figure 5 As shown, the shape of the through holes at the upper and lower ends of the pull plate 4 is a triangular hole, the pin 3 is a triangular pin, and the mounting holes on the upper and lower clamps are matching triangular holes.

Embodiment 3

[0051] A resin casting coil dry-type transformer structure, the structure is as described in Embodiment 1, the difference is that: the side of the pressure block 701 close to the high voltage resin coil is provided with reinforcing ribs. Adding reinforcing ribs on the side of the pressing block close to the high-voltage resin coil not only increases the strength of the pressing block, but also is more beautiful, and does not increase the bottom section, which will not affect the normal ventilation and heat dissipation of the air duct, and increases the distance between the high-voltage resin coil and the pressing nail. The creepage distance reduces the risk of partial discharge.

[0052] like Image 6 Shown, the shape of the through holes at the upper and lower ends of the pull plate 4 is a square hole, the pin 3 is a square pin (square pin), and the mounting holes on the upper and lower clamps are matching square holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com