Branched organosilicon epoxy resin curing agent and epoxy curing system

A technology of silicon epoxy resin and epoxy resin, which is applied in the direction of organic chemistry, chemical instruments and methods, compounds of group 4/14 elements of the periodic table, etc., can solve the problems of reduced electron cloud density, low reactivity, epoxy cross Bonding density and mechanical properties, etc., to achieve the effect of outstanding bonding performance and bending strength, wide application, and high dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

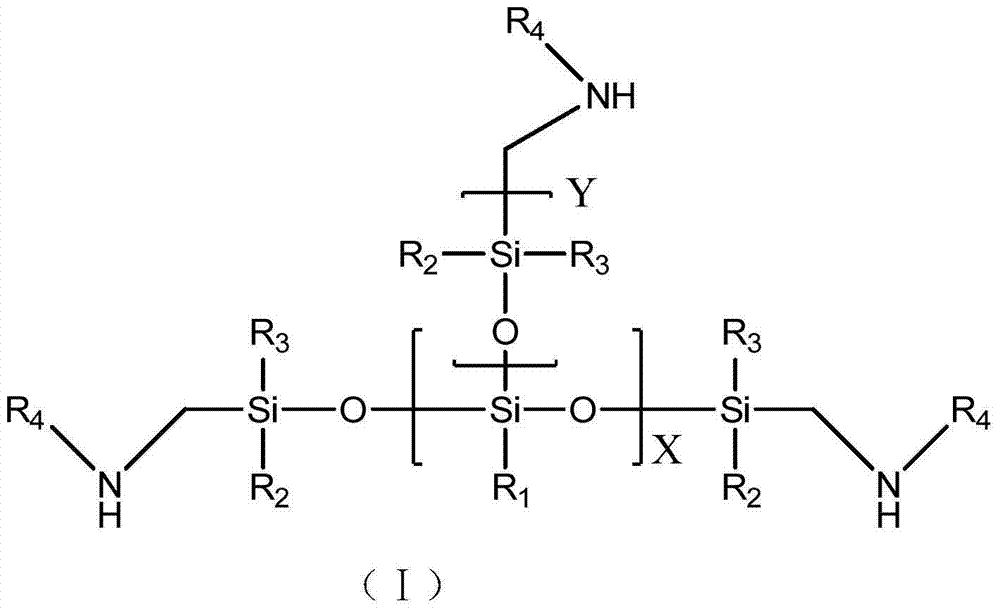

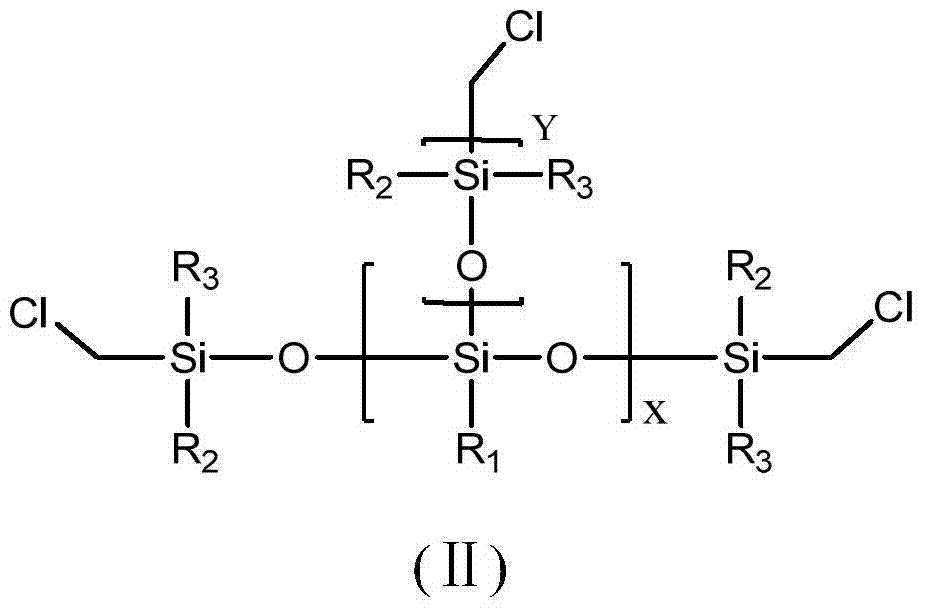

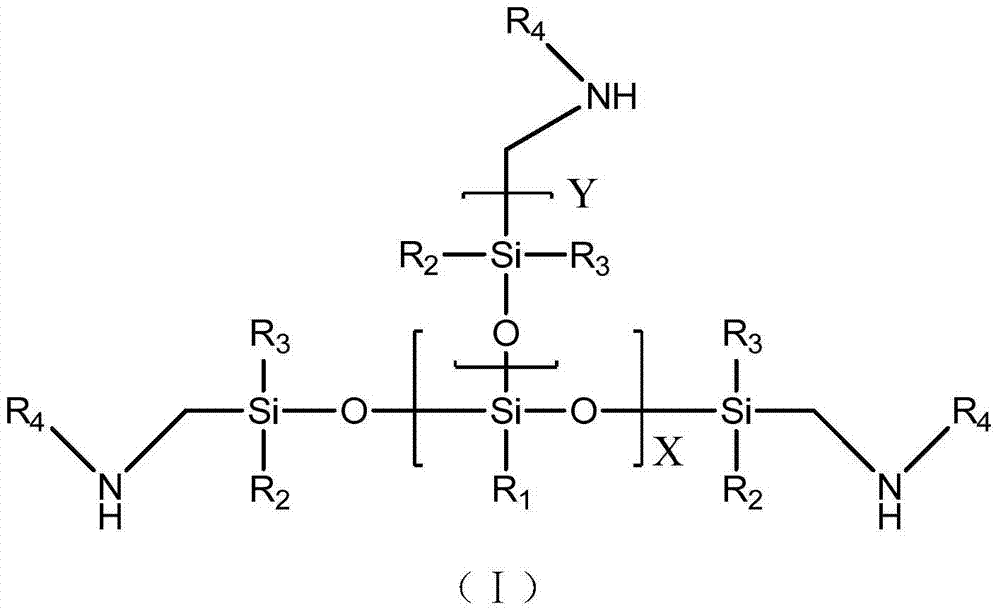

[0040] The present invention also provides a preparation method of the silicone epoxy resin curing agent, comprising:

[0041] Using compound (II) as raw material, directly drop it into compound (III) or their mixture under stirring, control the reaction temperature at 60-100°C, and the reaction time is 1-3h. After the reaction is completed, separate the lower curing agent layer, and Distill under reduced pressure to remove the raw materials to obtain compound (I) with a yield greater than 90%.

[0042]

[0043] R 4 -NH 2

[0044] (III)

[0045]Among them, X and Y are integers greater than 0, and R1, R2, and R3 are functional groups composed of one or more of the following chemical molecular structures: -H, -C n h 2n+1 , -NH 3 , -COOH, -SH, -C n h 2n -, -NH-, -COO-, Wait.

[0046] The present invention also provides an epoxy curing system comprising the branched silicone epoxy resin curing agent, in parts by weight, comprising:

[0047] 100 parts by weight...

Embodiment 1

[0060] Take the compound (II) with X=1, Y=1, R1, R2, and R3 as methyl groups as the raw material, directly drop it into the solution of p-phenylenediamine under stirring, control the reaction temperature at 60-70°C, and react Time 3h. After the reaction, the lower curing agent layer was separated, and the reaction raw materials were evaporated under reduced pressure to obtain No. (1) branched silicone epoxy resin curing agent with a yield of 92%.

[0061] Take 100 parts by weight of E-44 epoxy resin, 15 parts by weight of No. 1 curing agent, 0.4 parts by weight of 2-methylimidazole, stir for 0.5-1 hour and mix evenly, according to GB-T7124-1986 (Test of adhesive tensile shear strength Method) Spread evenly on the surface of the steel sheet cleaned with acetone and fix it, cure at 80°C for 30 minutes, and cure at 150°C for 1.5 hours. The bond strength was tested to be 13.5MPa, and the tensile modulus at the bond was 3230MPa.

[0062] Stir the resin, curing agent, and curing a...

Embodiment 2

[0064] Take compound (II) with X=1, Y=1, R1, R2, and R3 as methyl groups as the raw material, and directly drop it into aniline under stirring, control the reaction temperature at 70-80°C, and the reaction time is 3h. After the reaction, the lower curing agent layer was separated, and the reaction raw materials were distilled off under reduced pressure to obtain No. (2) branched silicone epoxy resin curing agent with a yield of 94%.

[0065] Take 100 parts by weight of E-44 epoxy resin, 35 parts by weight of No. 2 curing agent, 0.4 parts by weight of triethanolamine, stir for 0.5-1 hour to mix evenly, according to GB-T7124-1986 (Test method for tensile shear strength of adhesives) Apply to the surface of the steel sheet cleaned with acetone and fix it, cure at 80°C for 30 minutes, and cure at 150°C for 1.5 hours. Its bond strength is 11.8MPa, and the tensile modulus of the bond is 2650MPa.

[0066] Stir the resin, curing agent, and curing accelerator uniformly according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com