Epoxy casting mold with adjustable casting height and easy-to-disengage inner mold body

An epoxy pouring and easy-falling technology, which is applied in the field of transformers, can solve problems such as loose epoxy resin texture, missing, uneven top surface of epoxy resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

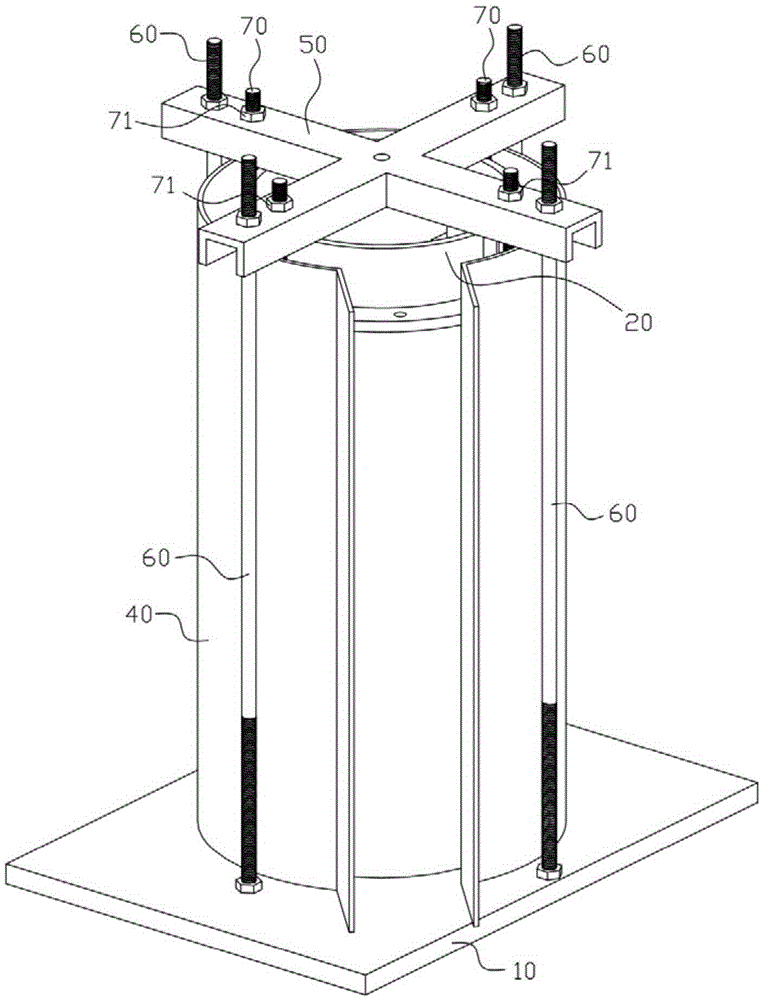

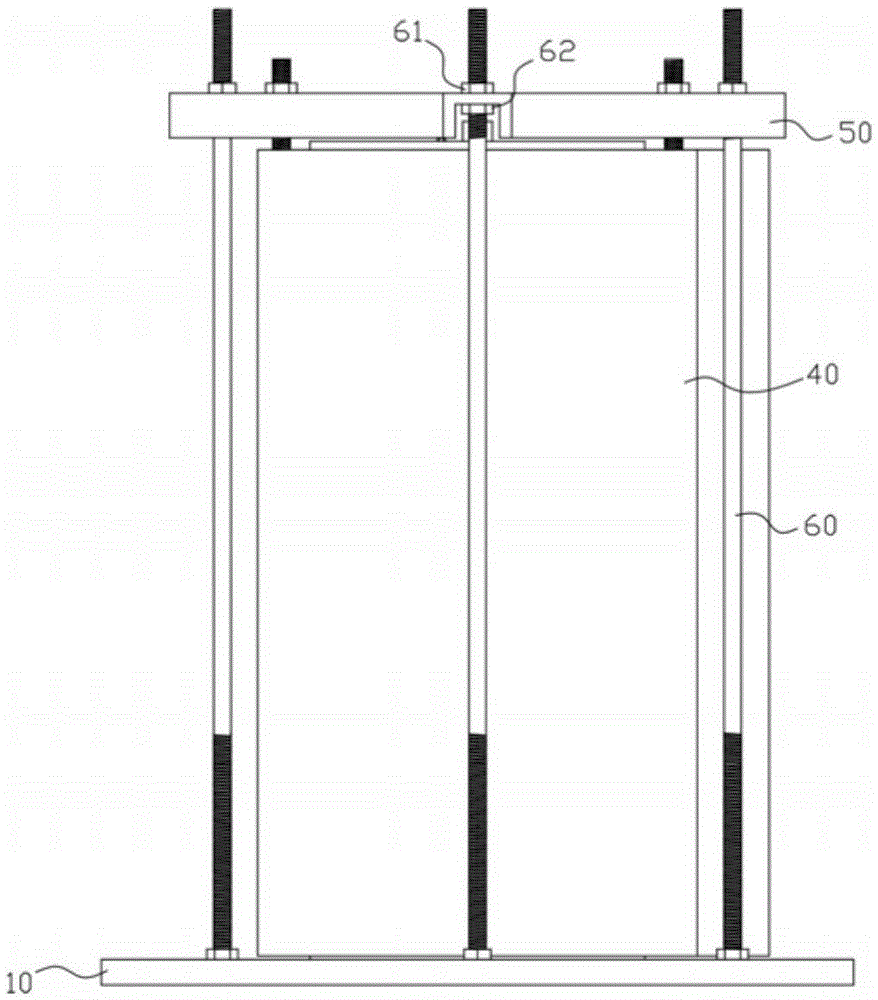

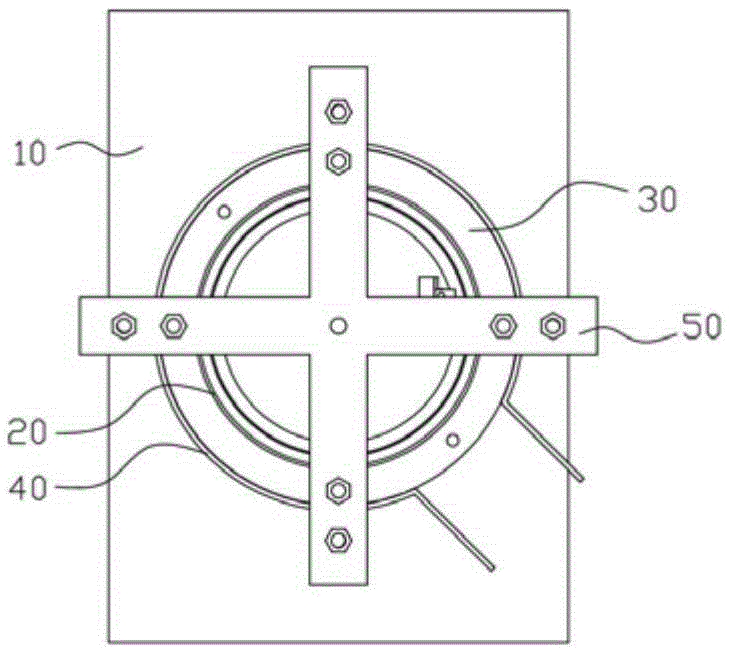

[0048] to combine Figure 1 to Figure 3 , an epoxy casting mold with adjustable pouring height and easy-to-fall-off inner mold, comprising a horizontally arranged bottom plate 10, an inner mold 20 vertically installed on the bottom plate, sleeved on the outer wall of the inner mold and can be placed along the outer side of the inner mold The upper end cover 30 with a lifting wall, the outer mold 40 sleeved on the periphery of the inner mold, and the pressing piece 50 located directly above the outer mold and the inner mold.

[0049] to combine image 3 , Figure 9 , the upper end cover is located between the inner mold and the outer mold, and a pouring port 301 is opened on the upper end cover.

[0050] to combine Figure 1 to Figure 3 , Figure 8 , Figure 9 , the long threaded rod 60 is installed on the base plate, and the long threaded rod is vertically arranged, and the first through hole 501 is opened in the pressure piece, and the top of the long threaded rod is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com