Vacuum assistant resin casted protection coating, system and method of permanent magnet motor rotor

A permanent magnet motor and vacuum-assisted technology, which is applied in the manufacture of motor generators, electric components, electromechanical devices, etc., can solve the problems of complex surface structure, inability to protect rotor poles from corrosion, uneven surfaces of poles and rotor yokes, etc., to achieve Strengthen mechanical properties, good perfusion effect, and improve the effect of anti-corrosion grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

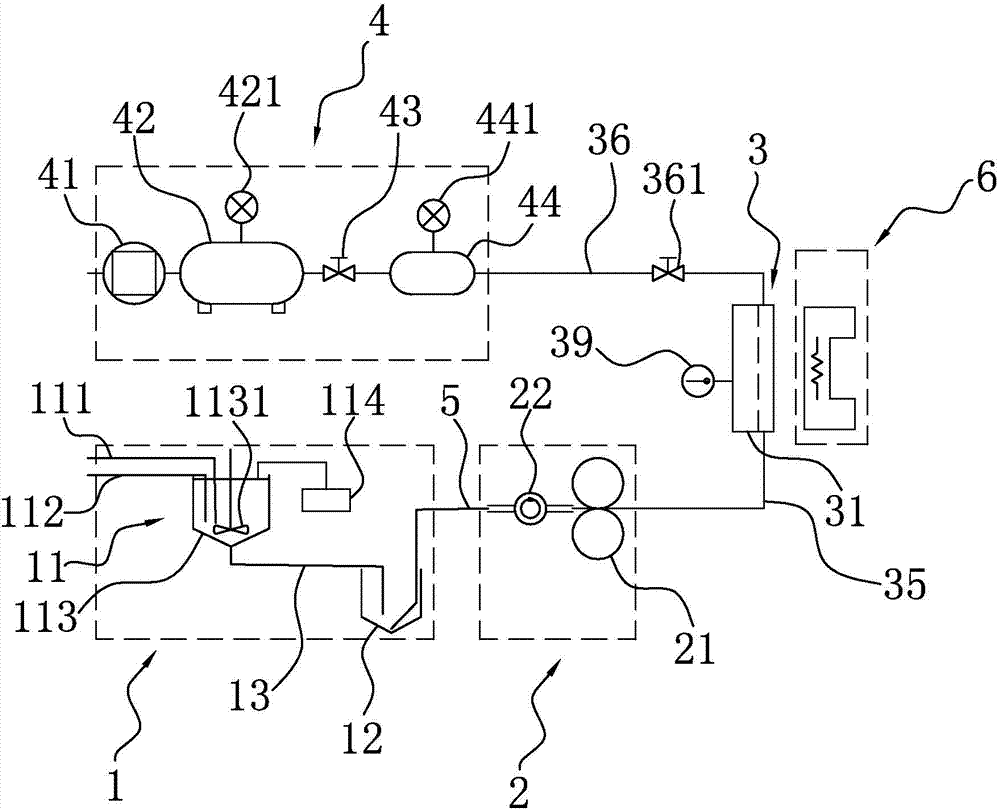

[0052] The vacuum assisted resin infusion protective coating of the permanent magnet motor rotor, the vacuum assisted resin infusion system of the permanent magnet motor rotor and the vacuum assisted resin infusion method of the permanent magnet motor rotor according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

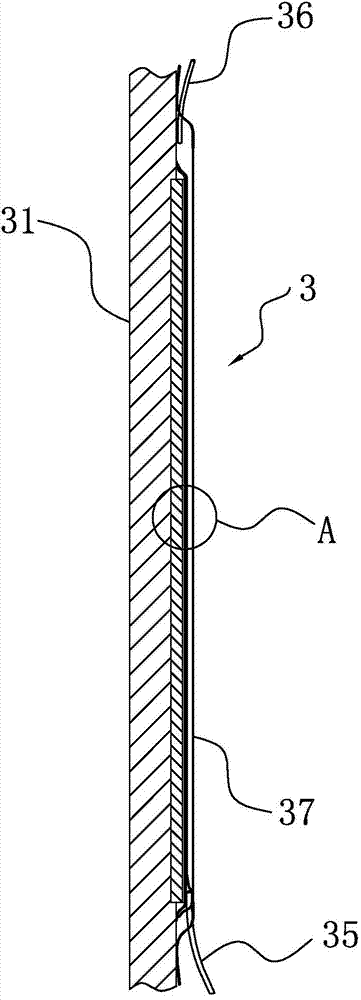

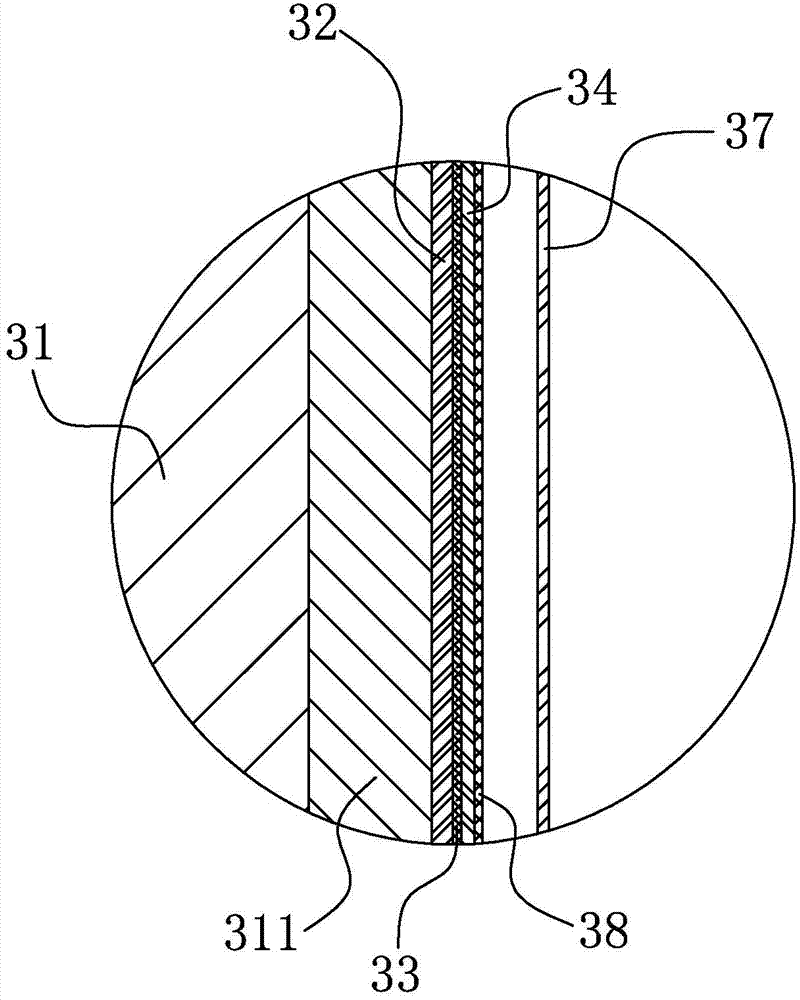

[0053] Such as figure 1 and figure 2 As shown, the vacuum-assisted resin infusion protective coating 3 of the permanent magnet motor rotor of this embodiment includes a reinforcement phase 32, a release cloth 33 and a flow guide net 34 laid on the surface of the rotor 31 with magnetic poles 311 in sequence. The end of the glue injection pipeline 35 and the end of the exhaust pipe 36 are respectively fixed outside the diversion net 34, and a vacuum isolation film 37 is sealed and connected to the rotor 31, and the vacuum isolation film 37 covers the reinforcement phase 32, the release cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com