Toughened epoxy resin/glass fiber prepreg and preparation method

A technology for toughening epoxy resin and glass fiber, which is applied in the field of toughening epoxy resin/glass fiber prepreg and its preparation, can solve the problems of high production cost, low resin content, low mechanical strength, etc., and achieves low cost, combined with The effect of ability enhancement and toughening effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

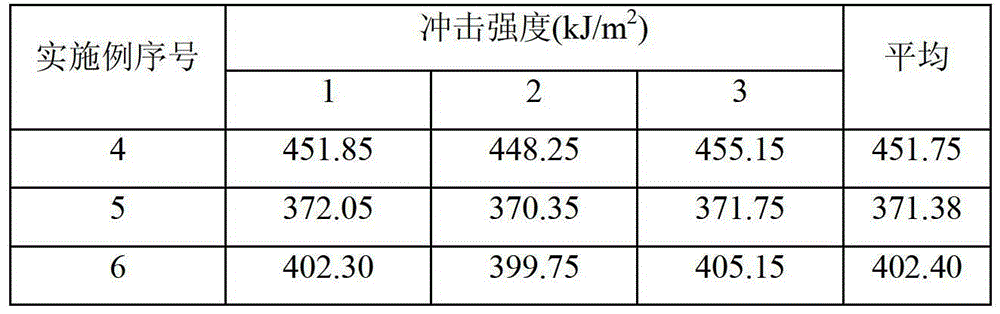

Examples

Embodiment 1

[0045] Embodiment 1—preparation of glass fiber woven cloth through plasma surface treatment

[0046] Specific steps are as follows:

[0047] Step 1. Glass fiber woven cloth is subjected to low temperature and atmospheric pressure plasma surface treatment

[0048] Put a roll of 5 kg pre-dried glass fiber woven cloth into the cavity of the plasma equipment, turn on the high-pressure air flow meter, adjust the pressure reducing valve, and turn on the power after the gas flow reaches an appropriate value, and adjust the discharge voltage to make the discharge After generating and stabilizing for 12 minutes, gradually reduce the output voltage of the power supply and return to zero, turn off the power supply and the gas pressure reducing valve, take out the treated glass fiber and glass fiber cloth, and set aside;

[0049] Step 2. Spray coupling agent dispersion

[0050] Preparation of coupling agent dispersion

[0051] Weigh 0.8 parts by weight of silane coupling agent vinyl t...

Embodiment 2

[0057] Example 2—Preparation of Dendrimer Functionalized Titanium Dioxide Submicron Particle Toughener

[0058] Specific steps are as follows:

[0059] Amino-terminated dendrimers G 6.0 -PAMAM-(NH 2 ) z (produced by Changchun Yinghua Institute) and titanium dioxide micro-particles are dispersed in acetone (other organic solvents can also be used, such as absolute ethanol, n-hexane, cyclohexane, toluene, etc.), and added to the reaction kettle with stirring and heating devices Among them, the titanium dioxide microparticles used here are microparticles with uniform particles obtained by hydrolysis of organic titanate. The preparation method is a method commonly used in the industry to prepare titanium dioxide microparticles. Hydrolysis occurs, and the particle size distribution of titanium dioxide microparticles obtained is narrow. By controlling the reaction conditions, the particle size can be controlled between 0.5 and 3.0 microns. The amount of titanium dioxide micropar...

Embodiment 3

[0060] Example 3—Preparation of Dendrimer Functionalized Silica Submicron Particle Toughener

[0061] Specific steps are as follows:

[0062] 0.5~3g of dendrimer G 6.0 -PAMAM-(NH 2 ) z (produced by Changchun Yinghua Institute) dispersed in 50-150ml of acetone (other organic solvents can also be used, such as absolute ethanol, n-hexane, cyclohexane, toluene, etc.), and then disperse 8-12g of nano-silica Add in 50-150ml of acetone, then add to the reaction kettle with stirring and heating device; raise the temperature of the reaction kettle to 78°C, stir and mix for more than 60 minutes; filter with suction, wash with acetone three times, and then dry, that is A dendrimer functionalized silica submicron particle toughening agent was obtained. Dendrimer G 6.0 -PAMAM-(NH 2 ) z It is a dendritic macromolecule with a hydrolyzable alkoxy silicon ester group in the center and a plurality of amino active groups at the end and can react with epoxy bisphenol A; the nano-silica is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com