Three-dimensional hollow-resin-poured luminous character structure and manufacturing method thereof

A production method and technology for luminous characters, which are applied to illuminated signs, instruments, display devices, etc., can solve the problems of uneven thickness of the color glue injection layer, resin leakage, surface color and light transmittance differences, etc., to avoid luminous Uneven, easy-to-operate, simple-to-method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

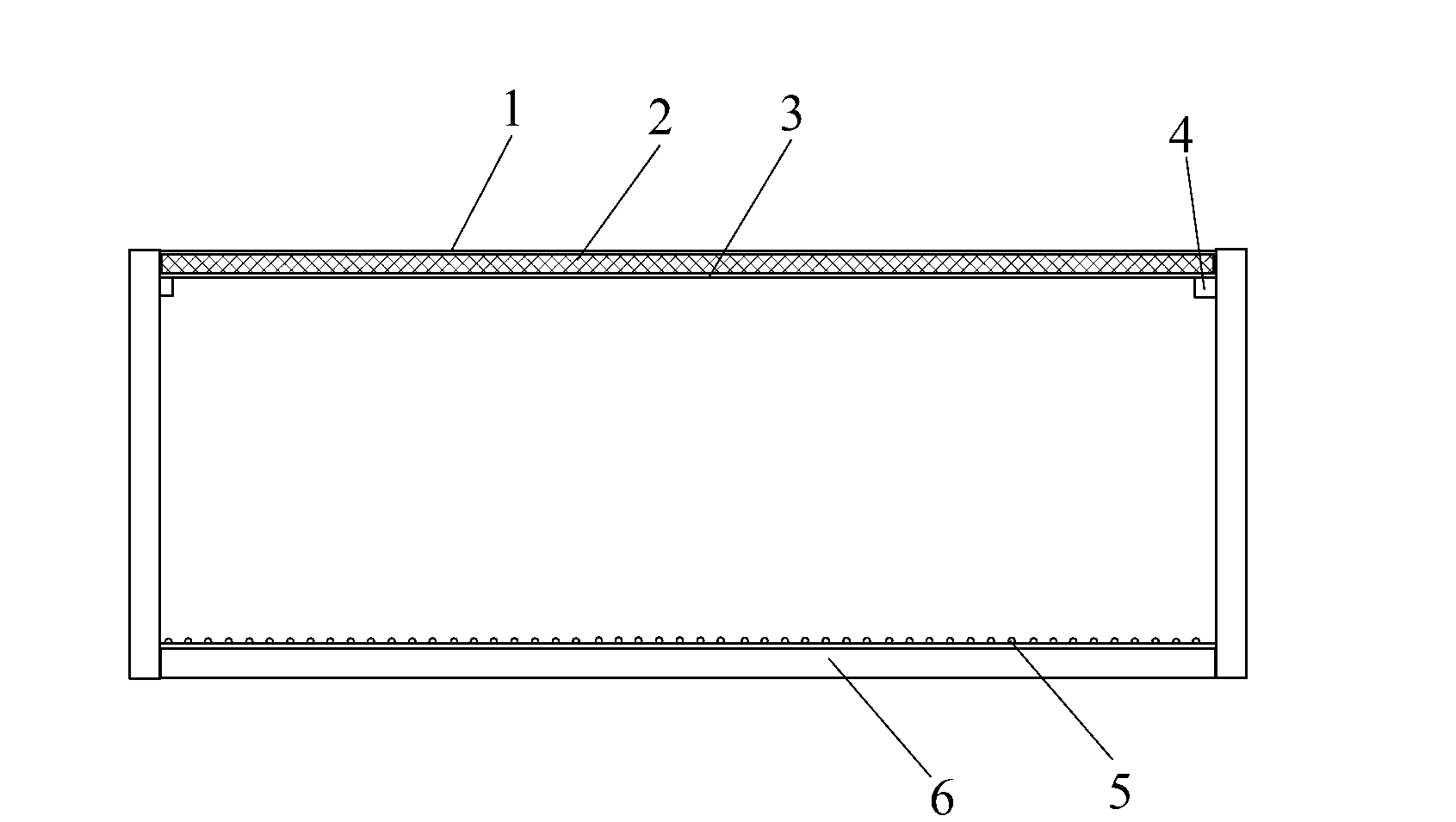

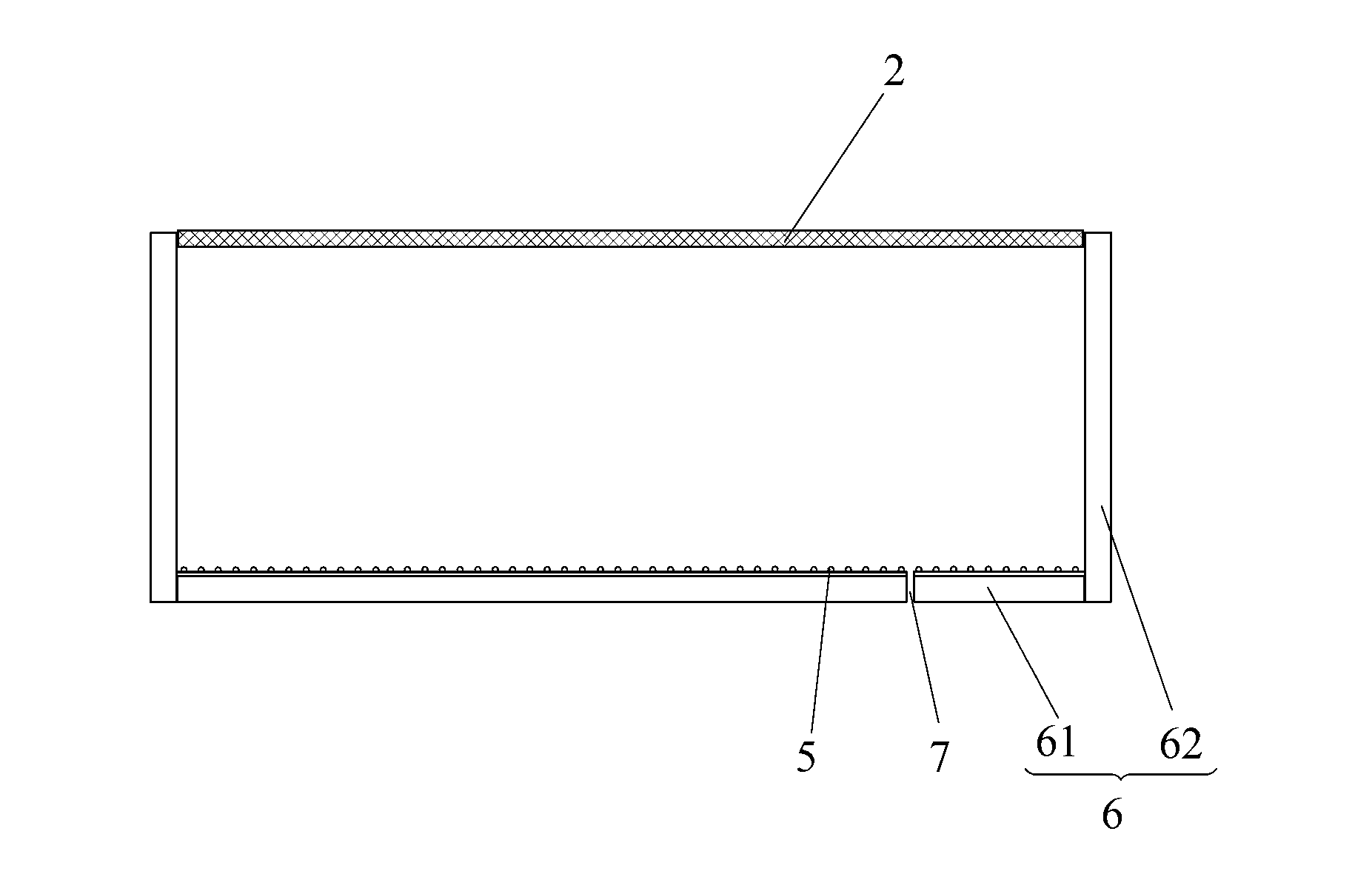

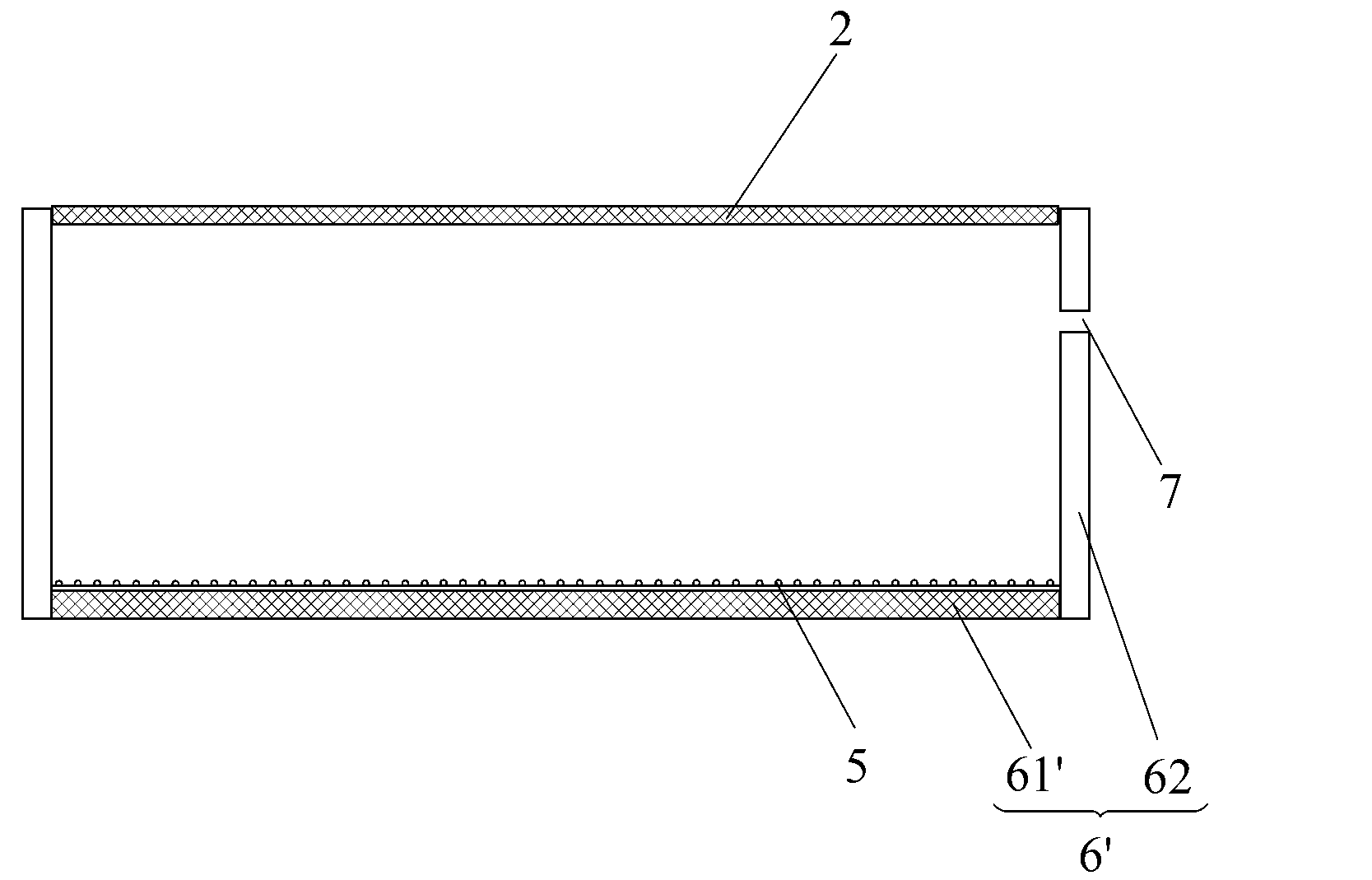

[0038] refer to figure 2 and image 3 , a three-dimensional hollow resin casting luminous character structure, including a shell 6, a light source 5 and a resin casting layer 2.

[0039] In one embodiment of the present invention, as figure 2 As shown, the housing 6 is an open structure surrounded by a bottom surface 61 and a side surface 62 . Only one side of the three-dimensional hollow resin casting luminous character structure is the resin casting layer 2, the middle part of the resin casting layer 2 is suspended, and the periphery is sealed and fixedly connected with the periphery of the open structure.

[0040] In another embodiment of the present invention, as image 3 As shown, the housing 6' is a cylindrical structure surrounded by side surfaces 62. In the three-dimensional hollow resin casting luminous character structure, both the front and the back of the character shell are resin casting layers 2 . The peripheries of the two-layer resin casting layer 2 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com