Multiple adsorption tower alternate internal recycle method for producing anhydrous alcohol

An anhydrous ethanol and adsorption tower technology, applied in chemical instruments and methods, methods for reacting gas medium with gas medium, total evaporation, etc., can solve problems such as the influence of adsorbent life, large cooling water consumption, and large instantaneous heat , to achieve the effects of reducing the area of the heat exchanger, high dehydration depth, and gradual decompression analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

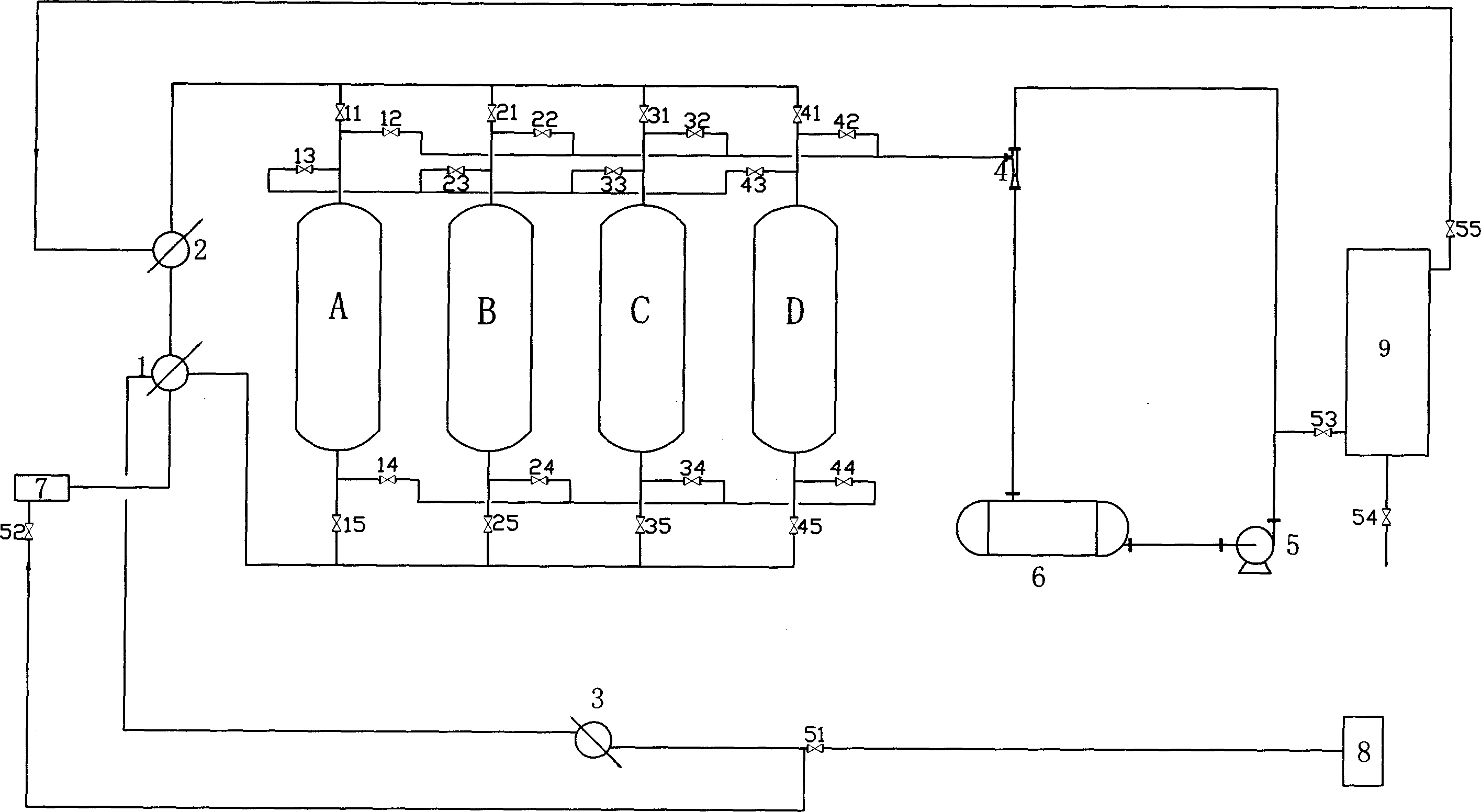

[0022] Refer to attached figure 1 As shown, the ethanol aqueous solution raw material with a concentration weight ratio of 70% enters the vaporizer 2 after exchanging heat with the product in the heat exchanger 1, and is vaporized by steam heating in the vaporizer 2, and is superheated to 80°C, and the superheated ethanol aqueous solution raw material The steam enters the adsorption tower A through the valve 11 from top to bottom, and at this time the valves 12, 13, 14, and 15 are closed; when the adsorption tower A absorbs for 250 seconds, the raw material steam of the superheated ethanol aqueous solution enters the adsorption tower B through the valve 21 from top to bottom Now, valves 22, 23, 24, and 25 are closed, the pressure of adsorption tower A and B is set to 0.1Mpa, and the adsorption time is set to 500 seconds; ethanol vapor flows out through valves 15, 25 at the bottom of the adsorption tower, and ethanol vapor after dehydration passes through the Heater 1 heats the...

Embodiment 2

[0028] Refer to attached figure 1 As shown, the ethanol aqueous solution raw material with a concentration weight ratio of 99% enters the gasifier after exchanging heat with the product through a heat exchanger, is heated and vaporized by the vaporizer steam, and is superheated to 220°C. And down enters adsorption tower A through valve 11, now valve 12,13,14,15 closes; Valves 22, 23, 24, and 25 are closed, the pressure of adsorption towers A and B is set to 2.5Mpa, and the adsorption time is set to 50 seconds; ethanol vapor flows out through valves 15 and 25 at the lower part of the adsorption tower, and ethanol vapor after dehydration passes through heat exchanger 1 Heating the ethanol raw material, cooling by the product cooler 3 after cooling, sampling and analysis to obtain anhydrous ethanol with a content of 99.99%, and entering the product storage tank 8 through the valve 51; if the ethanol content does not meet the requirements, enter the raw material ethanol storage ta...

Embodiment 3

[0034] Refer to attached figure 1 As shown, the ethanol aqueous solution raw material with a concentration weight ratio of 85% enters the gasifier after exchanging heat with the product through a heat exchanger, is heated and vaporized by the steam in the gasifier, and is superheated to 150°C. And down enters adsorption tower A through valve 11, now valve 12,13,14,15 closes; Valves 22, 23, 24, and 25 are closed, the pressure of adsorption towers A and B is set to 1.0Mpa, and the adsorption time is set to 250 seconds; the ethanol vapor flows out through valves 15 and 25 at the lower part of the adsorption tower, and the dehydrated ethanol vapor passes through heat exchanger 1 Heating the ethanol raw material, cooling by the product cooler 3 after cooling, sampling and analysis to obtain anhydrous ethanol with a content of 99.7%, and entering the product storage tank 8 through the valve 51; if the ethanol content does not meet the requirements, enter the raw material ethanol sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com