Catalyst for synthesizing dimethyl oxalate from CO and ultrasonic dispersion preparation method of catalyst

A technology of dimethyl oxalate and catalyst, which is applied in the field of catalyst and its preparation, can solve the problems of changing the dispersion of noble metal active components, and achieve the effects of ensuring stability, improving utilization rate, and high space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

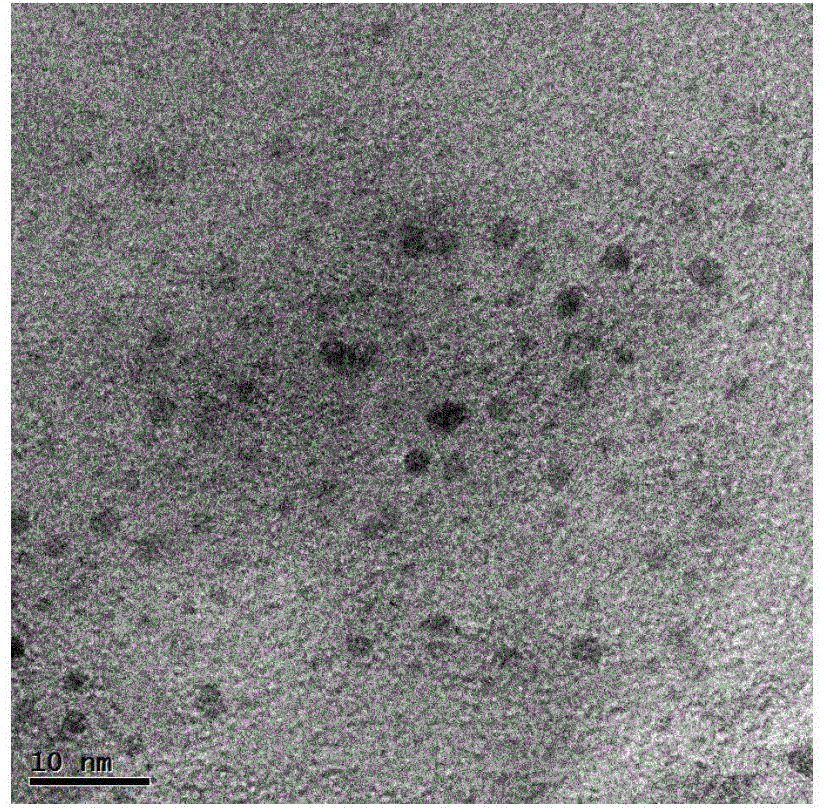

[0024] (1) Preparation of catalyst

[0025] Dissolve 0.075g palladium chloride and 0.40g auxiliary ferric nitrate in 15ml hydrochloric acid buffer with pH=1.1 volume, and add 15g alumina balls (diameter 2mm, obtained by rotating disc rolling ball method) that have been roasted at 1300℃ In the buffer solution, under the ultrasonic condition of 25Hz frequency, ultrasonic for 2min, place it at room temperature for 12h, then put it in a drying oven at 100℃ for 12h, then at 150℃ for 12h; use 5 times the volume at 60℃ Wash with deionized water 10 times with an interval of 2 to 3 hours. After the last time the soaked solution is poured out, put it in a 100 ℃ oven and continue to dry for 12 hours. The obtained palladium-loaded alumina ball is passed into CO:N 2 1:4 gas is reduced at 150~400℃ for 4h to obtain Pd-Fe / Al 2 O 3 Finished catalyst. The Pd content is 0.3% of the carrier mass, and the auxiliary iron content is 0.60% of the carrier mass.

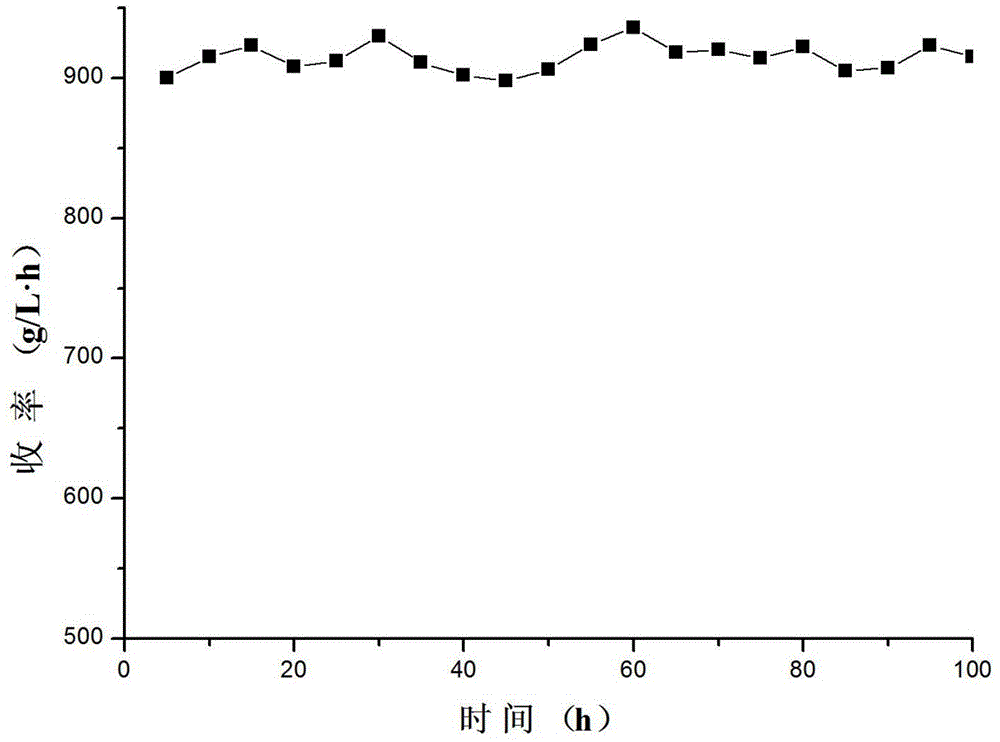

[0026] (2) Application performance evaluat...

Embodiment 2

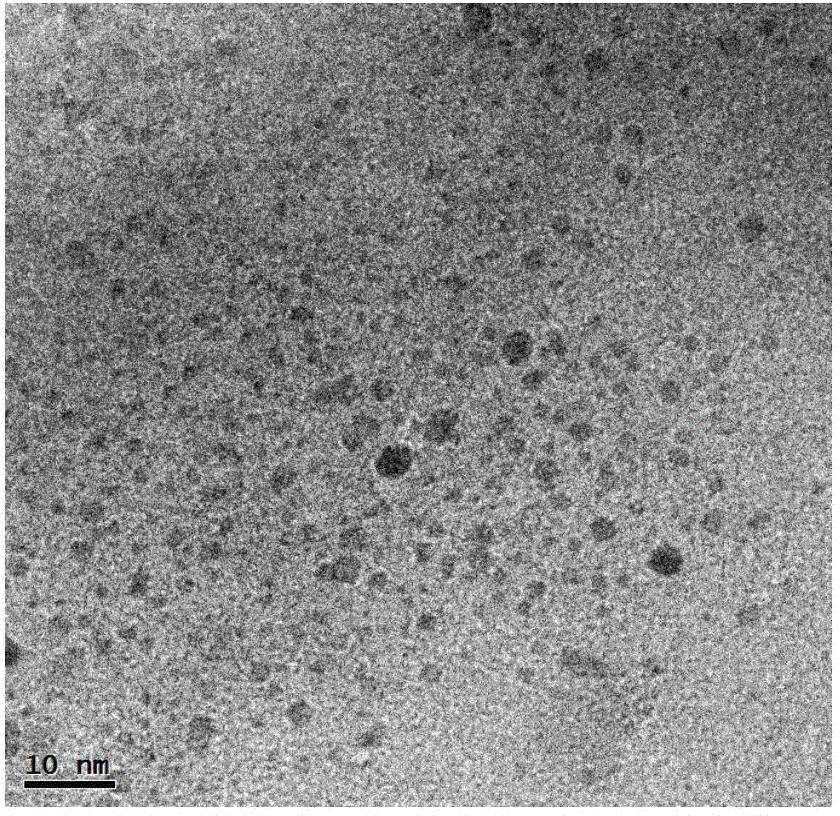

[0030] (1) Preparation of catalyst

[0031] Dissolve 0.075g palladium chloride and 0.20g auxiliary ferric nitrate in a 15ml hydrochloric acid buffer with pH=1.1 volume, add 15g of roasted alumina balls into the buffer, and sonicate under 25Hz ultrasonic conditions. After 3 minutes, place it at room temperature for 12 hours, then put it in a drying oven at 100°C for 12 hours and then at 150°C for 12 hours; wash 10 times with 5 times volume of deionized water at 60°C, with an interval of 2 to 3 hours After the immersed solution was poured out for the last time, put it in an oven at 100℃ and continue to dry for 12 hours, and pass the resulting palladium-loaded alumina ball into CO:N 2 1:4 gas is reduced at 150~400℃ for 4h to obtain Pd-Fe / Al 2 O 3 Finished catalyst. The Pd content is 0.3% of the carrier mass, and the auxiliary iron content is 0.30% of the carrier mass.

[0032] (2) Application performance evaluation

[0033] The same conditions as in Example 1 were used for evaluation,...

Embodiment 3

[0035] (1) Preparation of catalyst

[0036] Dissolve 0.075g palladium chloride and 0.27g auxiliary copper nitrate in 15ml hydrochloric acid buffer solution with pH=1.1 volume, add 15g alumina balls after roasting treatment into the buffer solution, under the ultrasonic condition of frequency 25Hz, ultrasonic After 2 minutes, place it at room temperature for 12 hours, then put it in a drying oven at 100°C for 12 hours, and then dry at 150°C for 12 hours; wash 10 times with 5 times volume of deionized water at 60°C, with an interval of 2 to 3 hours. After the immersed solution was poured out for the last time, put it in an oven at 100℃ and continue to dry for 12 hours, and pass the resulting palladium-loaded alumina ball into CO:N 2 1:4 gas is reduced at 150~400℃ for 4h to obtain Pd-Cu / Al 2 O 3 Finished catalyst. The Pd content is 0.3% of the carrier mass, and the auxiliary copper content is 0.60% of the carrier mass.

[0037] (2) Application performance evaluation

[0038] The same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com