Method for welding cathode flexible bus of aluminum electrolysis cell without series power failure

A cathode soft busbar and welding method technology, which is applied in the field of electrolytic aluminum, can solve the problems of short service life of thermite container, high space size requirements, difficult operation, etc., so as to avoid the inability to directly use exothermic welding, solve technical problems, Avoiding the effect of a series of blackouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

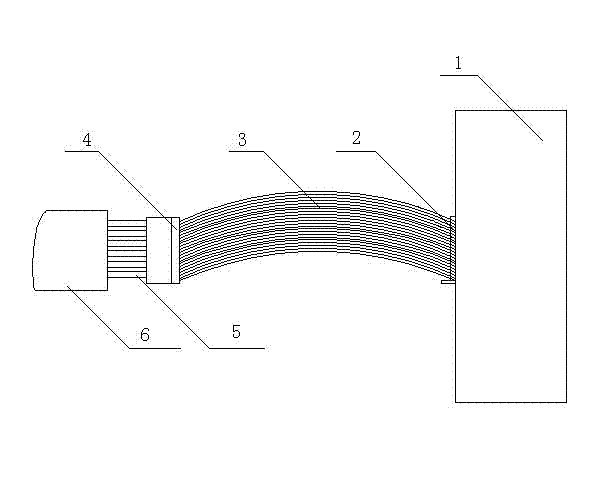

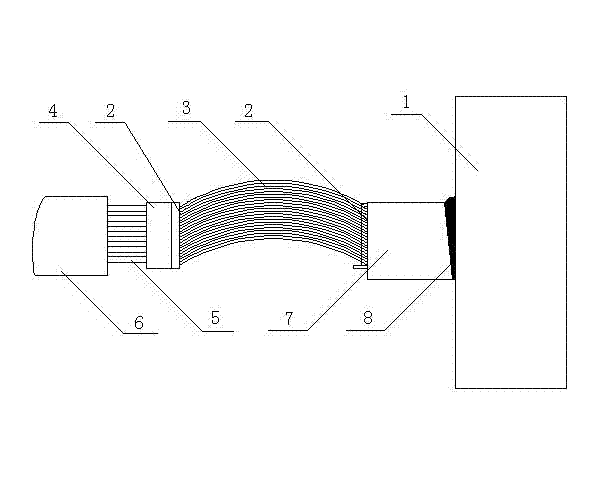

Image

Examples

Embodiment 1

[0043] 1. Disassemble the cathode soft busbar to be repaired together with the explosive block from the original position (cut with oxyacetylene flame), and at the same time flatten the welding plane of the cathode steel rod and connecting piece with oxyacetylene flame, and weld the soft busbar and aluminum busbar Surface cutting, smoothing and grinding.

[0044] 2. Cut the soft busbar that has been cut to be repaired into a length of 20cm in advance, weld it to the transitional aluminum block that has been prepared by argon arc welding, and cut and smooth the iron metal surface of the explosion block; or directly use a new Materials are crafted into new ones. This work has been done in other environments beforehand.

[0045] 3. Weld the above prepared transitional aluminum block, soft busbar and explosive block with connecting pieces, and the connecting pieces are pre-cut specified steel plates. This work is done on the electrolyzer.

[0046] 4. Adjust the gap of 2cm betwe...

Embodiment 2

[0053] 1. Disassemble the cathode soft busbar to be repaired together with the explosive block from the original position (cut with oxyacetylene flame), and at the same time flatten the welding plane of the cathode steel rod and connecting piece with oxyacetylene flame, and weld the soft busbar and aluminum busbar Surface cutting, smoothing and grinding.

[0054] 2. Cut the soft busbar that has been cut to be repaired into a length of 22.5cm in advance, weld it on the transitional aluminum block that has been prepared by argon arc welding, and cut and smooth the iron metal surface of the explosion block; or use it directly New materials make new ones. This work has been done in other environments beforehand.

[0055] 3. Weld the above prepared transitional aluminum block, soft busbar and explosive block with connecting pieces, and the connecting pieces are pre-cut specified steel plates. This work is done on the electrolyzer.

[0056] 4. Adjust the gap of 3.5cm between the ...

Embodiment 3

[0063] 1. Disassemble the cathode soft busbar to be repaired together with the explosive block from the original position (cut with oxyacetylene flame), and at the same time flatten the welding plane of the cathode steel rod and connecting piece with oxyacetylene flame, and weld the soft busbar and aluminum busbar Surface cutting, smoothing and grinding.

[0064] 2. Cut the soft busbar that has been cut to be repaired into a length of 25cm in advance, weld it to the transitional aluminum block that has been prepared by argon arc welding, and cut and smooth the iron metal surface of the explosion block; or directly use a new Materials are crafted into new ones. This work has been done in other environments beforehand.

[0065] 3. Weld the above prepared transitional aluminum block, soft busbar and explosive block with connecting pieces, and the connecting pieces are pre-cut specified steel plates. This work is done on the electrolyzer.

[0066] 4. Adjust the gap of 5cm betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com