Safety remote-control ignition rod

A safe, ignition rod technology, applied in thermite welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of operator's hand injury, etc., and achieve the effect of simple structure and simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

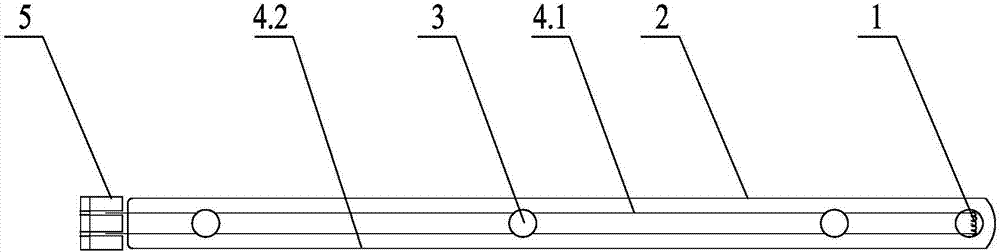

[0018] Such as figure 1 As shown, the safety-type remote control ignition rod includes a resistance wire 1, an introduction pipe 2, an insulating block 3, a first wire 4.1, a second wire 4.2 and a connector 5; inside the introduction pipe 2 along its length direction A first wire 4.1 and a second wire 4.2 are installed, the right end of the first wire 4.1 is connected to the right end of the second wire 4.2 through a resistance wire 1, and an insulating block 3 is arranged between the first wire 4.1 and the second wire 4.2 A socket 5 is provided on the left side of the left end of the introduction tube 2, and the left end of the first lead 4.1 and the left end of the second lead 4.2 are inserted into the socket 5.

[0019] When in use, after the graphite mold 8, the thermite flux 7 and the workpiece 9 to be welded are combined, the safety type remote control ignition rod of embodiment 1 is inserted into the reserved hole 10 on the graphite mold 8, and the lead wire 11 is conne...

Embodiment 2

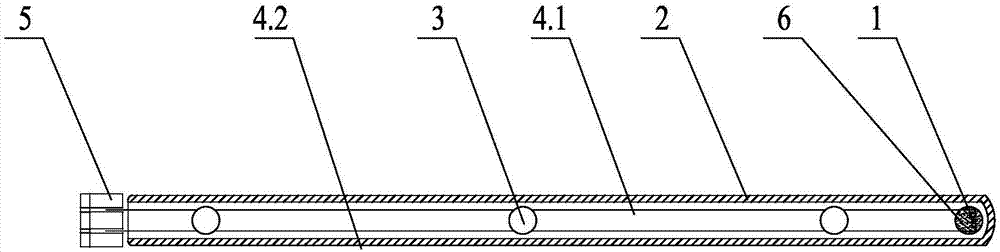

[0021] Such as figure 2 As shown, the safety-type remote control ignition rod includes a resistance wire 1, an introduction pipe 2, an insulating block 3, a first wire 4.1, a second wire 4.2 and a connector 5; inside the introduction pipe 2 along its length direction A first wire 4.1 and a second wire 4.2 are installed, the right end of the first wire 4.1 is connected to the right end of the second wire 4.2 through a resistance wire 1, and an insulating block 3 is arranged between the first wire 4.1 and the second wire 4.2 , on the left side of the left end of the introduction pipe 2 is provided with a socket 5, the left end of the first lead 4.1 and the left end of the second lead 4.2 are inserted into the socket 5; also includes a solid pilot fuel 6, a solid pilot fuel 6 Wrap the resistance wire 1 as a whole.

[0022] When in use, after the graphite mold 8, the thermite flux 7 and the workpiece 9 to be welded are combined, the safety type remote control ignition rod of emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com