In-situ power-cut-free welding method for soft mother belts and aluminum bus of cathode of aluminum electrolysis cell

A welding method and technology for an aluminum electrolytic cell, which are applied in the field of electrolytic aluminum, can solve the problems of weak interface bonding, complicated procedures, laborious and time-consuming, etc., and achieve the effects of high welding repair efficiency, simple method operation, and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

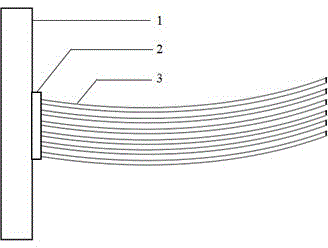

[0037] 1) In-situ grinding: Grinding from the end of the soft master tape pre-connected to the aluminum busbar, the length of the polish is 15mm, to remove the oxide film on the surface of this part, and keep the oxide film on other parts of the soft master tape.

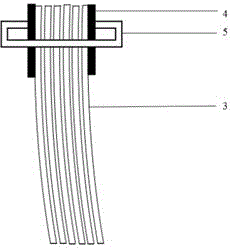

[0038] 2) Fixing in situ: The end of the soft master tape faces upwards, and the polished section is sandwiched between two fixing plates, and clamped with a clamp.

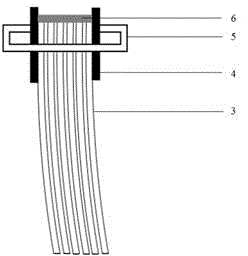

[0039] 3) In-situ melting: Use welding equipment to weld the end face of the soft master tape. The welding direction is along the soft master gap. Under the action of gravity and capillary, the molten aluminum flows down along the gap of the soft master tape and fills the grinding section. After the molten aluminum liquid cools and solidifies, a 12mm thick soft master tape block can be obtained at one end of the soft master tape.

[0040] 4) Pre-welding treatment in situ: place the soft master tape block close to the part of the aluminum busbar to...

Embodiment 2

[0044] 1) In-situ grinding: Grinding from the end of the soft master tape pre-connected to the aluminum bus bar, the length of the polish is 18mm, to remove the oxide film on the surface of this part, and keep the oxide film on other parts of the soft master tape.

[0045] 2) Fixing in situ: The end of the soft master tape faces upwards, and the polished section is sandwiched between two fixing plates, and clamped with a clamp.

[0046] 3) In-situ melting: Use welding equipment to weld the end face of the soft master tape. The welding direction is along the soft master gap. Under the action of gravity and capillary, the molten aluminum flows down along the gap of the soft master tape and fills the grinding section. After the molten aluminum liquid cools and solidifies, a 15mm thick soft master tape block can be obtained at one end of the soft master tape.

[0047] 4) Pre-welding treatment in situ: place the soft master tape block close to the part of the aluminum busbar t...

Embodiment 3

[0051] 1) In-situ grinding: Grinding from the end of the soft master tape pre-connected to the aluminum busbar, with a length of 22mm, to remove the oxide film on the surface of this part, and keep the oxide film on other parts of the soft master tape.

[0052] 2) Fixing in situ: The end of the soft master tape faces upwards, and the polished section is sandwiched between two fixing plates, and clamped with a clamp.

[0053] 3) In-situ melting: Use welding equipment to weld the end face of the soft master tape. The welding direction is along the soft master gap. Under the action of gravity and capillary, the molten aluminum flows down along the gap of the soft master tape and fills the grinding section. After the molten aluminum liquid cools and solidifies, a 20mm thick soft master tape block can be obtained at one end of the soft master tape.

[0054] 4) Pre-welding treatment in situ: put the soft master tape block close to the part of the aluminum bus bar to be welded, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com