Exothermic welding powder for welding novel grounding grid materials

A grounding grid and thermite welding technology, which is applied in the direction of thermite welding equipment, welding/cutting medium/material, welding medium, etc., can solve problems such as air holes, slag inclusions, and unfavorable development of grounding systems in power engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

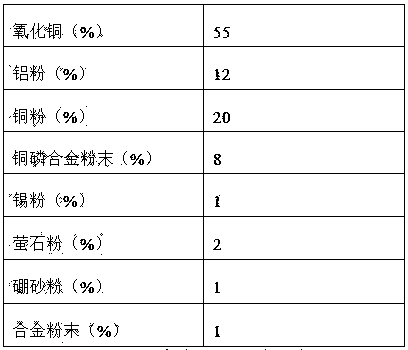

[0018] A thermite welding powder for novel grounding grid materials, consisting of the following substances by weight percentage:

[0019]

[0020] Among them, the oxidation degree of copper oxide is 85%, and the particle size is 30 mesh; the purity of metal aluminum powder is ≥98%, and the particle size is 200 mesh; the purity of metal copper powder is ≥99.5%, and the particle size is 200 mesh; the phosphorus content of copper-phosphorus alloy is 14 %, particle size is 100 mesh; metal tin powder purity ≥ 98.5%, particle size 300 mesh; fluorite powder purity ≥ 98.5%, particle size 200 mesh; borax purity ≥ 95%, particle size 100 mesh; the alloy powder particle size ≥ 300 The alloy powder components and weight fractions are Ca: 10%, Si: 45%, Ba: 30%, and the rest are impurities.

Embodiment 2

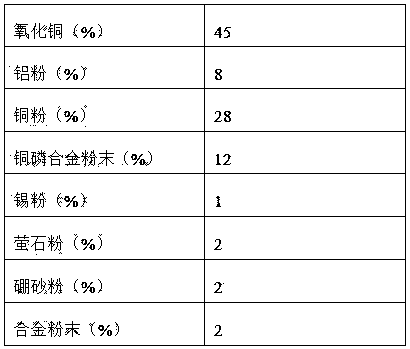

[0022] A thermite welding powder for novel grounding grid materials, consisting of the following substances by weight percentage:

[0023]

[0024] Among them, the oxidation degree of copper oxide is 85%, and the particle size is 200 mesh; the purity of metal aluminum powder is ≥98%, and the particle size is 30 mesh; the purity of metal copper powder is ≥99.5%, and the particle size is 30 mesh; the phosphorus content of copper-phosphorus alloy is ≥14 %, the particle size is 300 mesh; metal tin powder purity ≥ 98.5%, particle size 300 mesh; fluorite powder purity ≥ 98.5%, particle size 100 mesh; borax purity ≥ 95%, particle size 300 mesh; the alloy powder particle size 100 The alloy powder components and weight fractions are Ca: 10%, Si: 45%, Ba: 30%, and the rest are impurities.

Embodiment 3

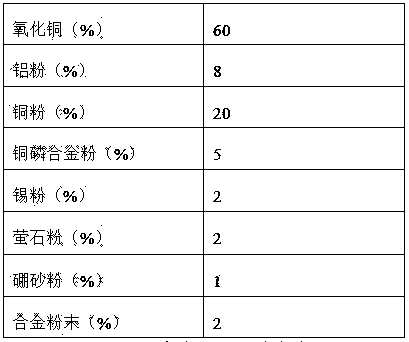

[0026] A thermite welding powder for novel grounding grid materials, consisting of the following substances by weight percentage:

[0027]

[0028] Among them, the oxidation degree of copper oxide is 85%, and the particle size is 150 mesh; the purity of metal aluminum powder is ≥98%, and the particle size is 150 mesh; the purity of metal copper powder is ≥99.5%, and the particle size is 130 mesh; the phosphorus content of copper-phosphorus alloy is 14 %, particle size is 260 mesh; metal tin powder purity ≥ 98.5%, particle size 280 mesh; fluorite powder purity ≥ 98.5%, particle size 1800 mesh; borax purity ≥ 95%, particle size 200 mesh; The alloy powder components and weight fractions are Ca: 10%, Si: 45%, Ba: 30%, and the rest are impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com