Electrolytic tank aluminum bus and soft tape electric heat-release welding method

A technology of exothermic welding and aluminum busbar, which is applied in the field of aluminum electrolysis, can solve problems such as welding difficulties, achieve the effects of reducing repair costs, saving costs, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] The method of the invention is based on the principle of exothermic welding, and the aluminum bus bar of the 200kA electrolytic cell and the soft belt live welding mold are designed and successfully carried out the live welding.

[0096] Electrolytic cell aluminum busbar and soft strip live exothermic welding method:

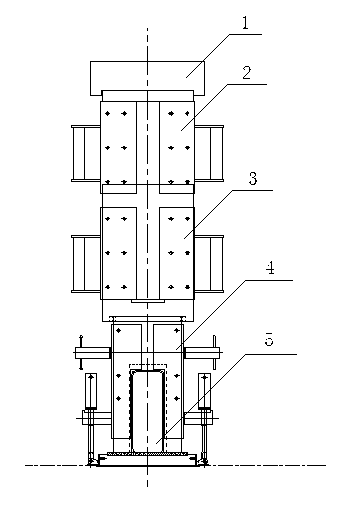

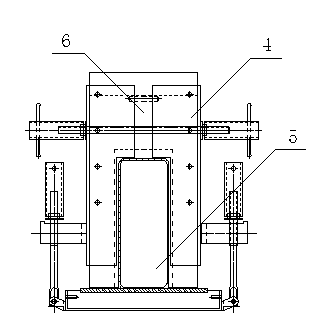

[0097] 1. Mold design for live repair aluminum busbar and aluminum soft strip

[0098] The material of the soft strip busbar and the busbar is aluminum, so the research on the live repair of the soft busbar is to realize aluminum-aluminum welding.

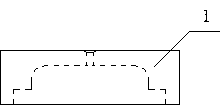

[0099] ) selection of crucible material

[0100] The crucible is one of the basic tools for exothermic welding. It is mainly used to accommodate flux for thermite reaction. The temperature of thermite reaction in the crucible is very high, generally above 2000°C. At the same time, it is accompanied by strong boiling. Therefore, the crucible material or lining material is required to have high refractorines...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com