Self-propagating welding powder

A self-propagating welding and welding powder technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the safety threats of construction personnel, reduce welding heat, and copper oxide is easy to absorb moisture and agglomerate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, use a precision electronic scale to weigh various powders according to the following proportions:

[0023] Barite 40% 500 mesh

[0024] Al 15% 500 mesh

[0025] Cu 38% 200 mesh

[0026] CaF 7% 400 mesh

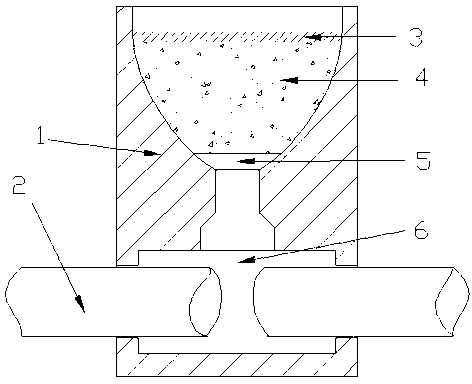

[0027] When starting welding, put the copper cable 2 into the small hole under the mold, and reserve a space of about 5mm between the two copper cable wires. Preheat the copper cable after putting it in, and the final preheating temperature is 300°C to 400°C. Then the above powders are evenly mixed together according to the specified ratio. Place a self-fusing plug (thin copper sheet) at the bottom of the graphite crucible 1, then put the mixed self-spreading solder powder 4 into the crucible 1, and evenly sprinkle a layer of gunpowder 3 on the solder powder. After the gunpowder 3 is ignited, the gunpowder can cause the welding powder 4 to start to react, and the reaction continues. When the powder reaction is completed, the reaction product is the mol...

Embodiment 2

[0030] First, use a precision electronic scale to weigh various powders according to the following proportions:

[0031] Barite 50% 200 mesh

[0032] Al 30% 200 mesh

[0033] Cu 15% 50 mesh

[0034] CaF 5% 400 mesh

[0035] When starting welding, put the copper cable 2 into the small hole under the mold, and reserve a space of about 5mm between the two copper cables. Preheat the copper cable after putting it in, and the final preheating temperature is 300°C to 400°C. Then the above powders are evenly mixed together according to the specified ratio. Place a self-fusing plug (thin copper sheet) at the bottom of the graphite crucible 1, then put the mixed self-spreading solder powder 4 into the crucible 1, and evenly sprinkle a layer of gunpowder 3 on the solder powder. After the gunpowder 3 is ignited, the gunpowder can cause the welding powder 4 to start to react, and the reaction continues. When the powder reaction is completed, the reaction product is molten coppe...

Embodiment 3

[0038] First, use a precision electronic scale to weigh various powders according to the following proportions:

[0039] Barite 45% 200 mesh

[0040] Al 23% 200 mesh

[0041] Cu 25% 200 mesh

[0042] CaF 7% 400 mesh

[0043] When starting welding, put the copper cable 2 into the small hole under the mold, and reserve a space of about 5mm between the two copper cables. Preheat the copper cable after putting it in, and the final preheating temperature is 300°C to 400°C. Then the above powders are evenly mixed together according to the specified ratio. Place a self-fusing plug (thin copper sheet) at the bottom of the graphite crucible 1, then put the mixed self-spreading solder powder 4 into the crucible 1, and evenly sprinkle a layer of gunpowder 3 on the solder powder. After the gunpowder 3 is ignited, the gunpowder can cause the welding powder 4 to start to react, and the reaction continues. When the powder reaction is completed, the reaction product is molten copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com