Aluminum-steel heat release welding method

An exothermic welding and aluminum block technology, applied in the direction of aluminothermic welding equipment, welding equipment, welding medium, etc., can solve the problems of aluminum-steel welding joint performance degradation, uncontrolled cost, low economic efficiency, etc., and achieve easy access , Simple structure, stable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

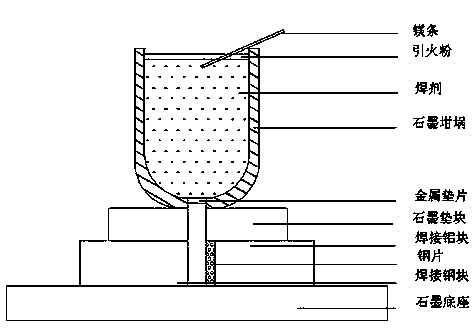

[0029] Grind the sections of the aluminum block and steel block to be welded with the same cross-sectional area, and place a pre-polished steel sheet of moderate size between the aluminum block and the steel block to be welded. The cross-sectional shape of the steel sheet is an inverted triangle , with a thickness of 3 mm; the aluminum block and the steel block according to figure 1 As shown, it is placed under the graphite crucible, and the center of the gap is aligned with the through hole at the bottom of the graphite crucible; there is a graphite base under the aluminum block and steel block, and there is a graphite pad with a through hole between the aluminum block, steel block and the graphite crucible. The through hole at the bottom of the graphite crucible is blocked by a metal sheet. The mass percentages were 22% of Al powder (fineness of 200 mesh), 68% of Fe 2 o 3 powder, 7% Si powder and 3% CaF 2 Put the powder in a powder mixer, mix evenly to form flux, then pu...

Embodiment 2

[0031] Grind the sections of the aluminum block and steel block to be welded with the same cross-sectional area, and place a pre-polished steel sheet of moderate size between the aluminum block and the steel block to be welded. The cross-sectional shape of the steel sheet is an inverted triangle , with a thickness of 3 mm; the aluminum block and the steel block according to figure 1 As shown, it is placed under the graphite crucible, and the center of the gap is aligned with the through hole at the bottom of the graphite crucible; there is a graphite base under the aluminum block and steel block, and there is a graphite pad with a through hole between the aluminum block, steel block and the graphite crucible. The through hole at the bottom of the graphite crucible is blocked by a metal sheet. The mass percentages were 24% of Al powder (fineness of 200 mesh), 66% of Fe 2 o 3 Powder, 6% Si powder and 4% NaF powder are placed in a powder mixer, mixed evenly to form flux, then t...

Embodiment 3

[0033]Grind the sections of the aluminum block and steel block to be welded with the same cross-sectional area, and place a pre-polished steel sheet of moderate size between the aluminum block and the steel block to be welded. The cross-sectional shape of the steel sheet is an inverted triangle , with a thickness of 3 mm; the aluminum block and the steel block according to figure 1 As shown, it is placed under the graphite crucible, and the center of the gap is aligned with the through hole at the bottom of the graphite crucible; there is a graphite base under the aluminum block and steel block, and there is a graphite pad with a through hole between the aluminum block, steel block and the graphite crucible. The through hole at the bottom of the graphite crucible is blocked by a metal sheet. The mass percentages were 26% of Al powder (fineness of 200 mesh), 64% of Fe 2 o 3 powder, 5% Si powder and 5% KF powder in a powder mixer, mix evenly to form flux, then put the flux int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com