Heat resistant magnesium alloy

A magnesium alloy, weight percentage technology, applied in the field of alloys, can solve the problems of slow cooling rate, damage to alloy properties, and inability to use sand casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

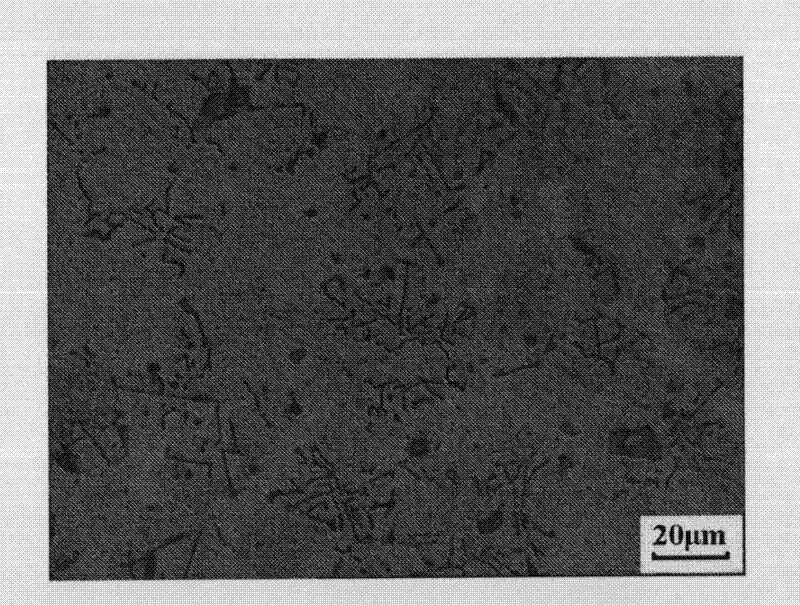

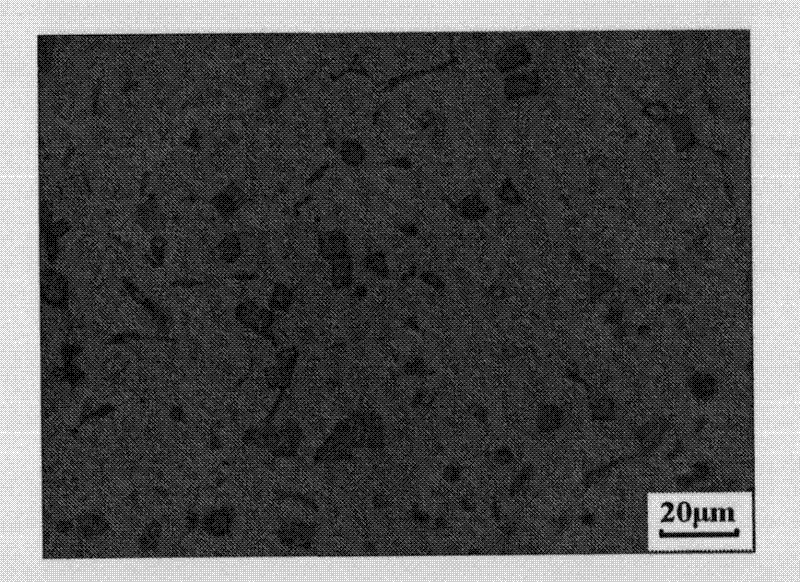

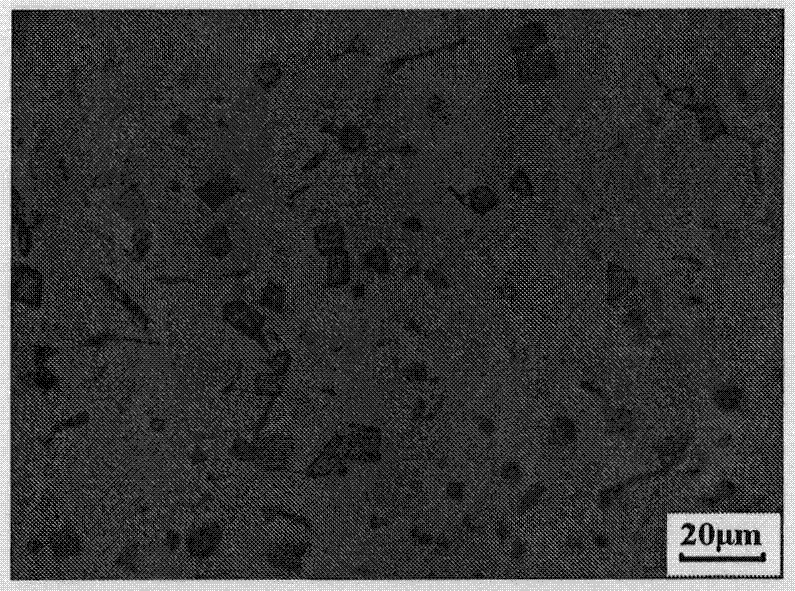

Image

Examples

Embodiment Construction

[0016] The preparation process of the magnesium alloy is carried out according to the following steps: batching magnesium ingots, aluminum ingots, zinc ingots, industrial fast-melting silicon, magnesium-calcium, and magnesium-strontium master alloys according to weight percentage; into SF 6 and N 2 Mix protective gas, add magnesium ingots, aluminum ingots and zinc blocks (>99.9%); continue to heat and melt the ingredients, raise the furnace temperature to 710-720°C, add industrial fast-melting silicon sawn into pieces, and raise the furnace temperature to 725-740°C and keep warm for 15-40min, stirring evenly; lower the furnace temperature to 710-720°C, add magnesium-calcium, magnesium-strontium intermediate alloy, keep warm for 10-15min, stir evenly; after standing for 10-15min, remove the surface Oxide, poured into the metal mold, out of the mold to cool.

[0017] The as-cast alloy is heat-treated by solution treatment, the solution temperature is 405-420°C, and the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com