Multi-Functional Cryogenic Storage Vessel

a cryogenic storage and multi-functional technology, applied in the field of vessel devices, to achieve the effect of reducing embrittlement, maximizing flexibility and resistance, and limited adjustmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

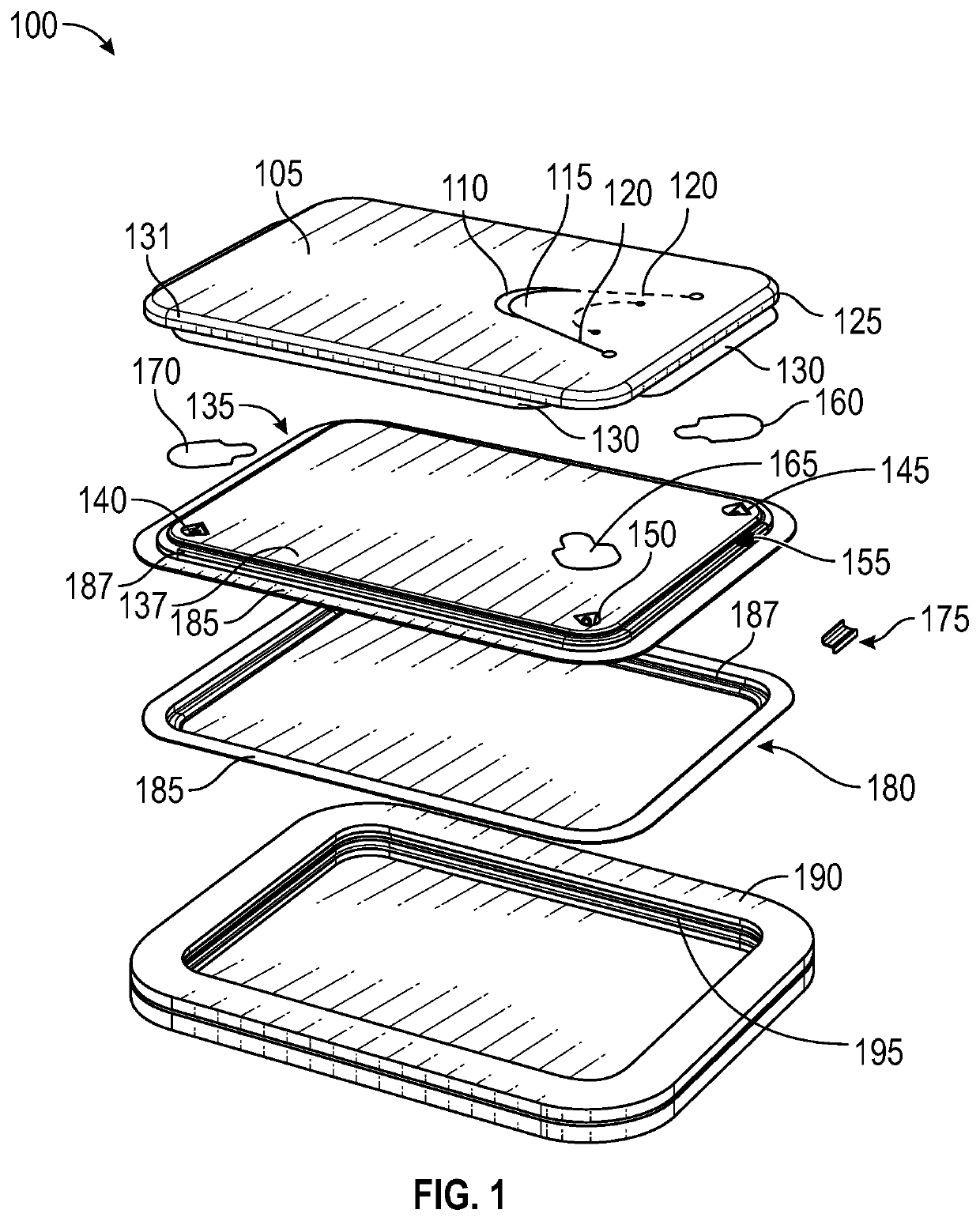

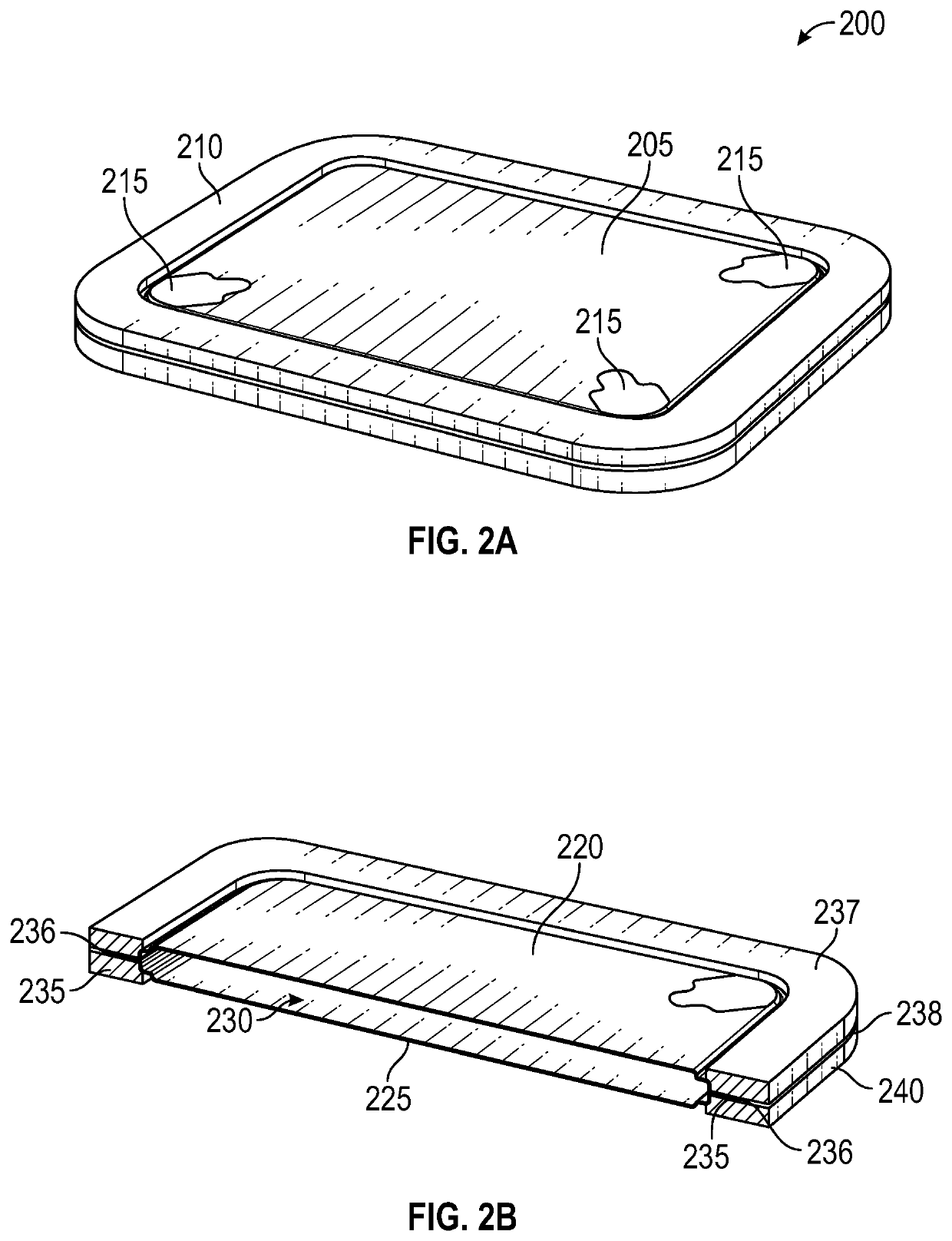

[0056]The present invention provides storage vessels and storage systems for cryogenically preserved cell suspensions that satisfy a number of properties and functionalities that are not offered in vessels that are currently available. In some embodiments, the vessels of the present invention provide a means of containment of a liquid and / or aqueous solution, for example, a solution, a composition, a formulation, a particulate suspension, a viral suspension, a cellular suspension, and a multicellular organism suspension. In some embodiments, the liquid is contained within a vessel by a barrier of a singular material wherein various parts comprising the vessel are joined by fusion bonds of the singular material, and as such are not vulnerable to separation of parts and failure of bonds under the stresses imposed by exposure to low and cryogenic temperatures. In some embodiments, the singular material has the properties of retaining toughness, flexibility, and resistance to fracture a...

PUM

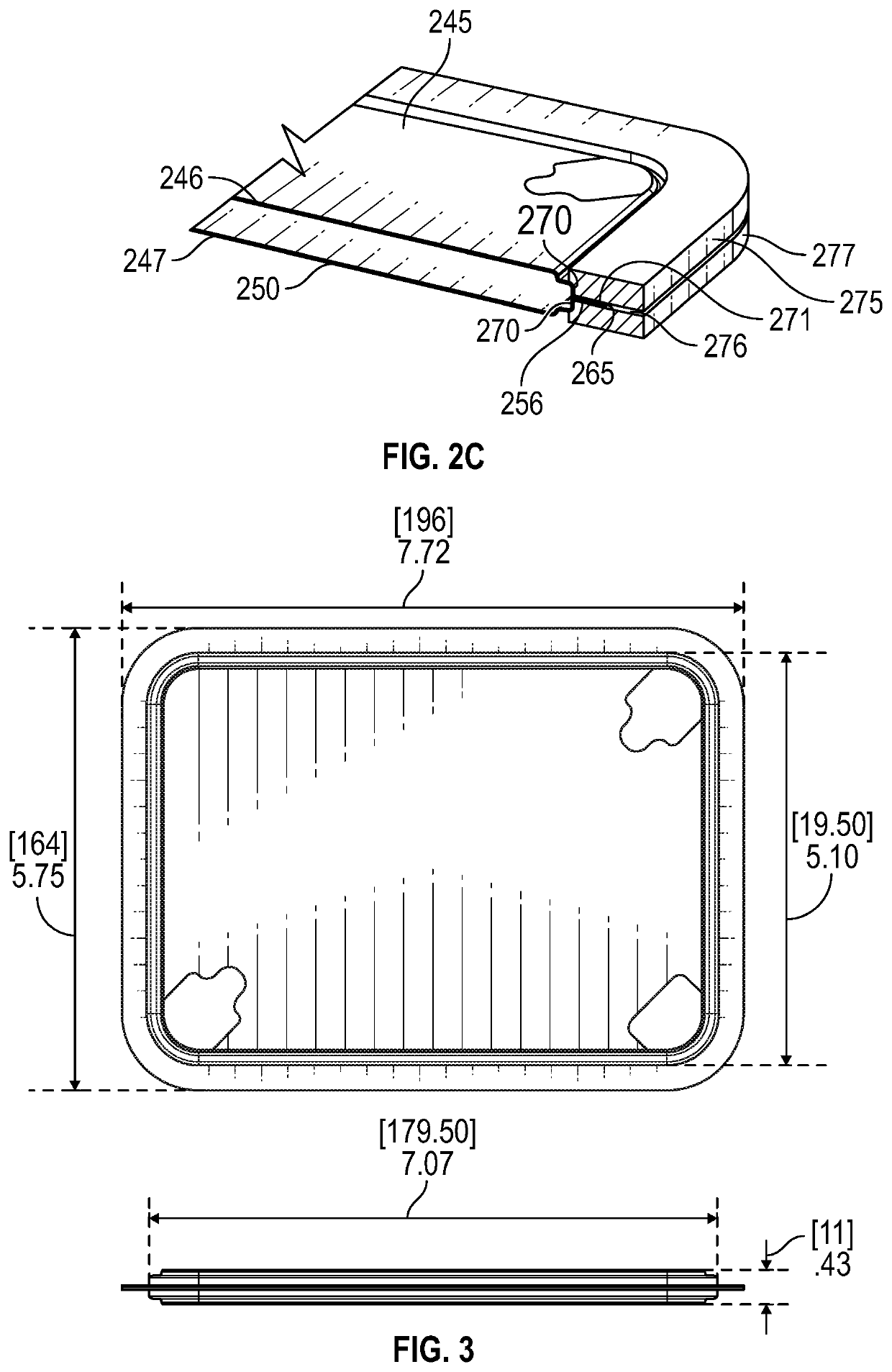

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com