Temperature self-adaptive automobile shock absorber

An automobile shock absorber, self-adaptive technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve problems such as shock absorber temperature failure, to speed up the temperature control process, ensure viscosity, avoid The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

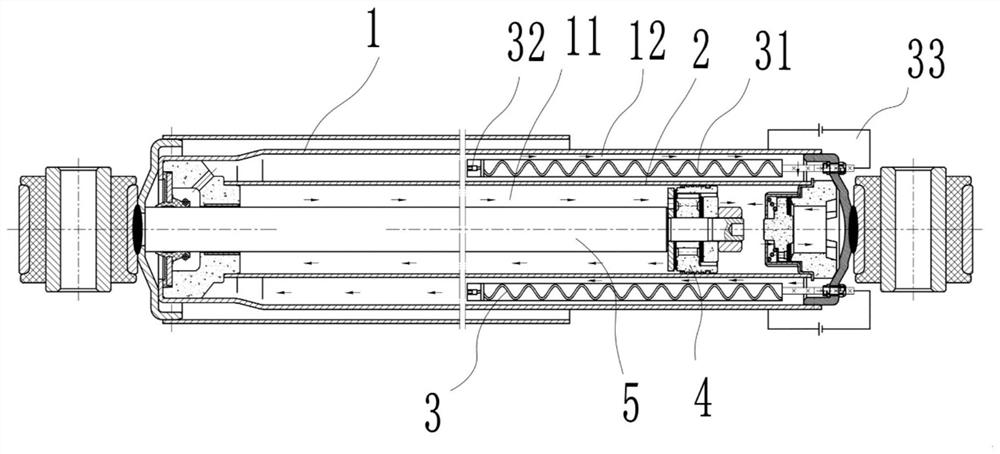

[0030] Example 1 ( figure 1 shown)

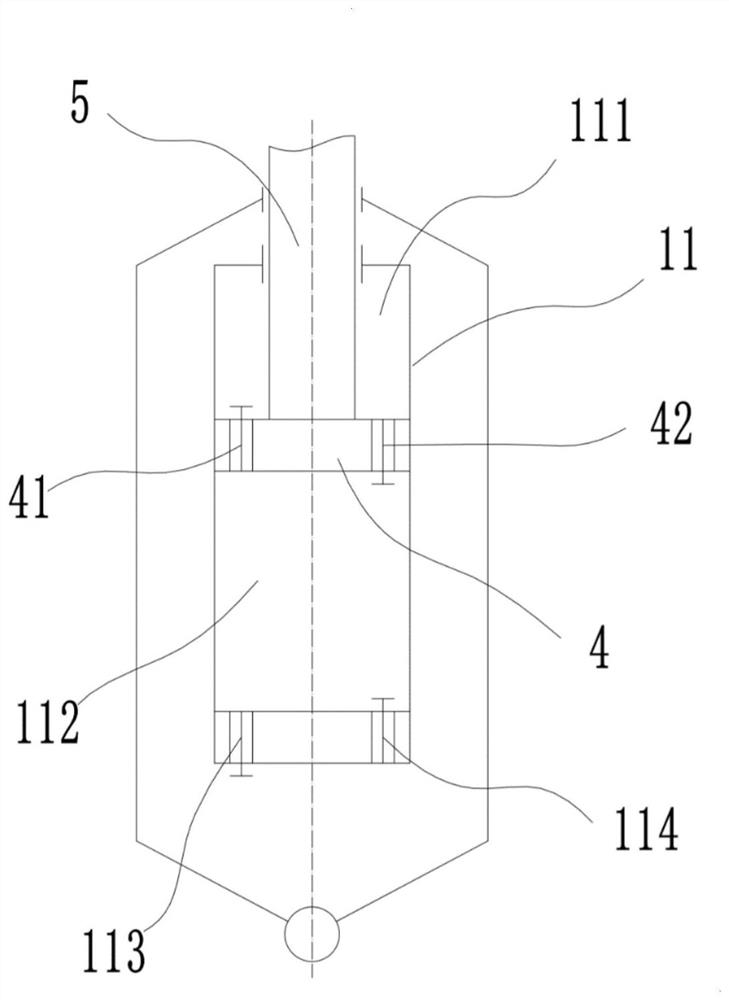

[0031] The temperature adaptive automobile shock absorber includes a damping cylinder 1, and the damping cylinder 1 includes a working chamber 11 and a liquid storage chamber 12 separated by a working cylinder 2, and the working chamber 11 and the liquid storage chamber 12 are communicated through a valve. The working chamber 11 and the liquid storage chamber 12 are filled with oil, the working chamber 11 is provided with a piston 4 , and the liquid storage chamber 12 is provided with a temperature control device 3 .

[0032] The temperature control device 3 includes a first heating wire 31, a first temperature sensor 32 and a first control circuit 33, the first heating wire 31 and the first temperature sensor 32 are arranged inside the liquid storage chamber 12, and the first temperature sensor 32 is externally connected to a controller , the first heating wire 31 is controlled by the first control circuit 33 , and the first control circu...

Embodiment 2

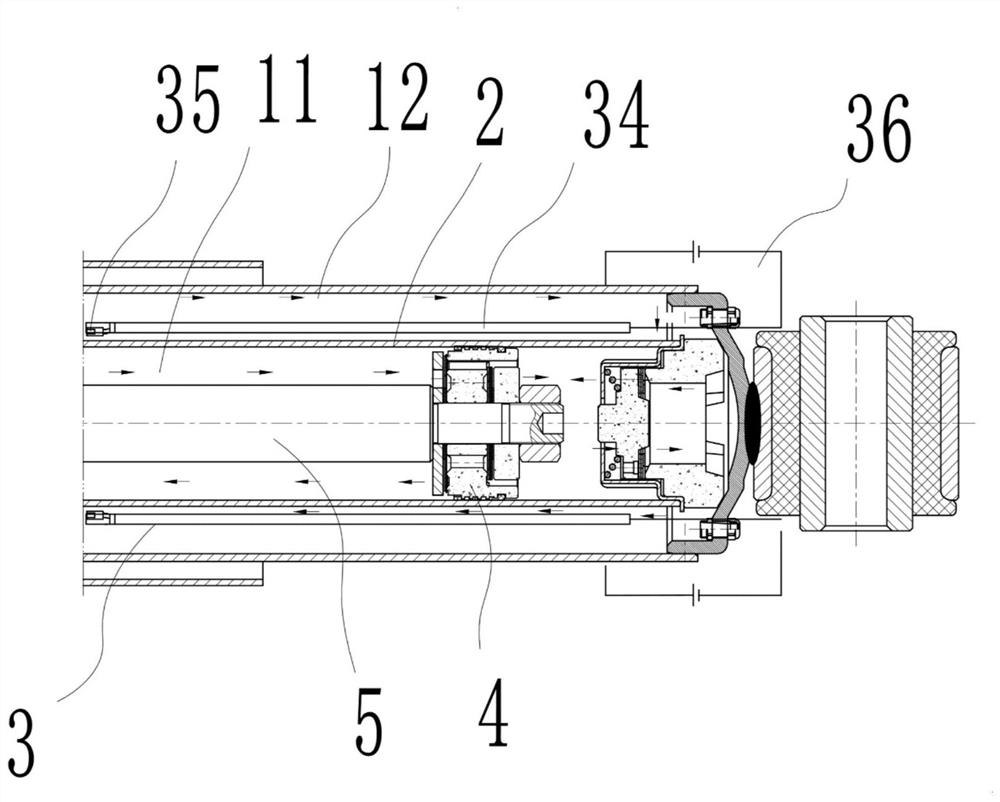

[0033] Example 2 ( image 3 shown)

[0034] The temperature adaptive automobile shock absorber includes a damping cylinder 1, and the damping cylinder 1 includes a working chamber 11 and a liquid storage chamber 12 separated by a working cylinder 2, and the working chamber 11 and the liquid storage chamber 12 are communicated through a valve. The working chamber 11 and the liquid storage chamber 12 are filled with oil, the working chamber 11 is provided with a piston 4 , and the liquid storage chamber 12 is provided with a temperature control device 3 .

[0035] The temperature control device 3 includes a second heating wire 34 , a second temperature sensor 35 and a second control circuit 36 , and the second heating wire 34 and the second temperature sensor 35 are arranged on the working cylinder 2 . The second heating wire 34 is set in sheet form on the surface or inside of the working cylinder 2 , the second temperature sensor 35 is set on the surface or inside of the wor...

Embodiment 3

[0037] Embodiment 3 ( Figure 4 shown)

[0038] The temperature adaptive automobile shock absorber includes a damping cylinder 1, and the damping cylinder 1 includes a working chamber 11 and a liquid storage chamber 12 separated by a working cylinder 2, and the working chamber 11 and the liquid storage chamber 12 are communicated through a valve. The working chamber 11 and the liquid storage chamber 12 are filled with oil, the working chamber 11 is provided with a piston 4 , and the liquid storage chamber 12 is provided with a temperature control device 3 .

[0039] The temperature control device 3 includes a first heating wire 31, a first temperature sensor 32 and a first control circuit 33, the first heating wire 31 and the first temperature sensor 32 are arranged inside the liquid storage chamber 12, and the first temperature sensor 32 is externally connected to a controller , the first heating wire 31 is controlled by the first control circuit 33 , and the first control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com