Die for exothermic welding of grounding grid and welding method

A technology of exothermic welding and grounding grid, applied in aluminothermic welding equipment, welding equipment, welding equipment, etc., can solve the problem of large current load capacity, and achieve the effect of strong corrosion resistance, fast welding speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

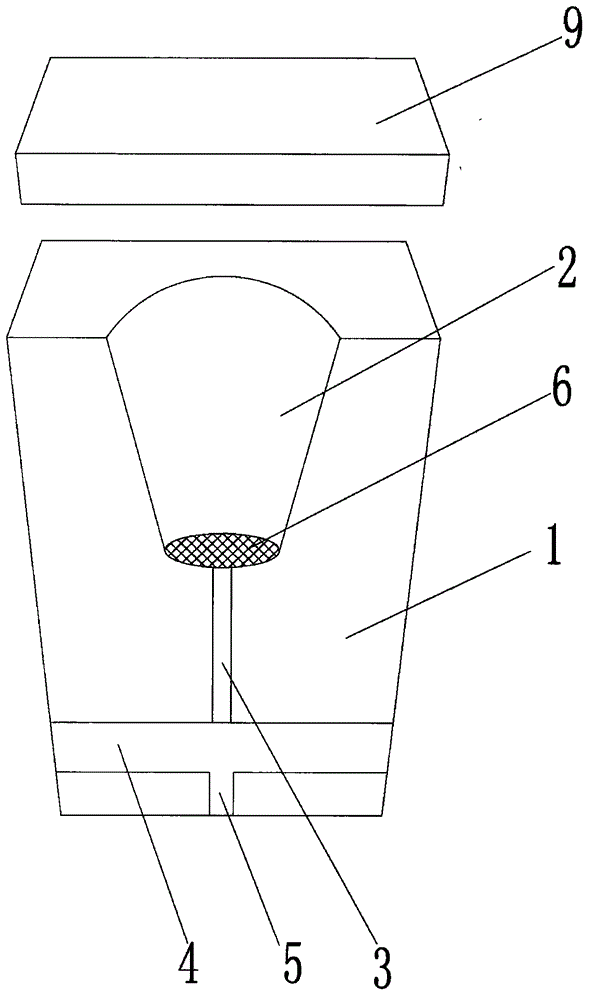

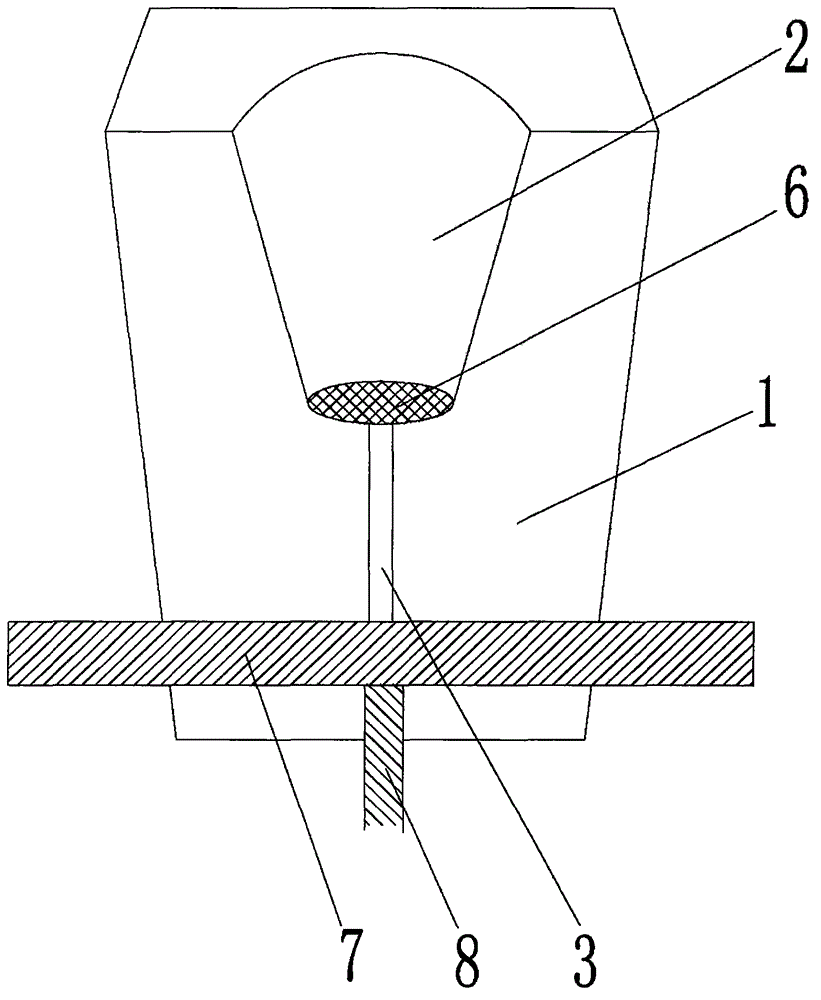

[0036] Please refer to the attached figure 1 And attached figure 2 As shown, the present invention is a mold for exothermic welding of grounding grids, which includes a mold body 1, which is symmetrically arranged left and right, so as to facilitate mold closing and mold opening.

[0037] A solder powder filling area 2 , a mold cavity 3 , a copper bar placement cavity 4 and a ground rod placement cavity 5 are sequentially arranged in the mold body 1 from top to bottom. A mold cover 9 is also covered on the top of the mold body 1 .

[0038] Wherein, the lower part of the solder powder filling area 2 is connected to the mold cavity 3, which is tapered from top to bottom, so as to facilitate the convergence of molten exothermic flux. A supporting piece 6 is provided between the solder powder filling area 2 and the mold cavity 3 , and the supporting piece 6 prevents exothermic flux before reaction from flowing into the mold cavity 3 .

[0039] The copper bar placement cavity 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com