Patents

Literature

49results about How to "High overload performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

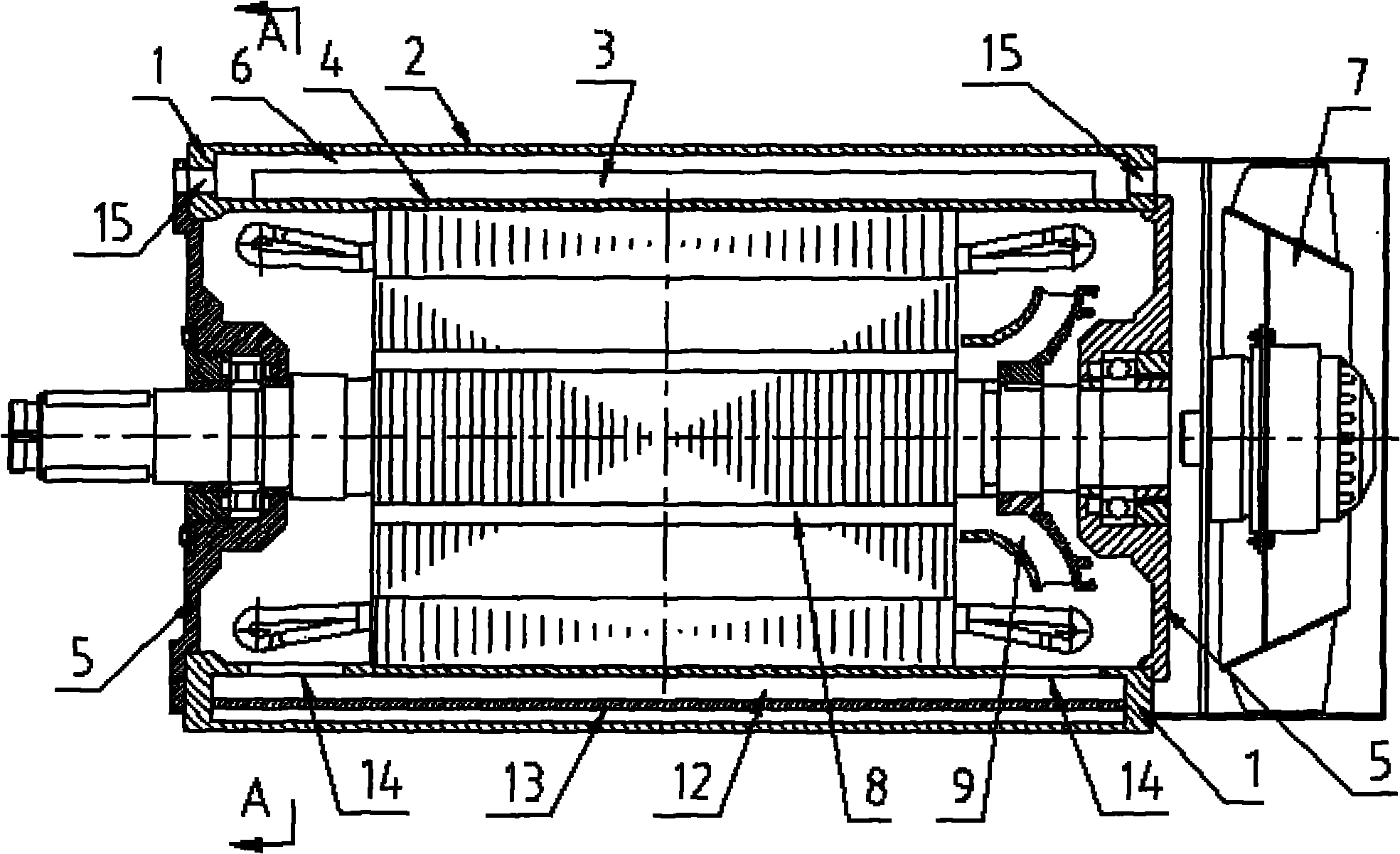

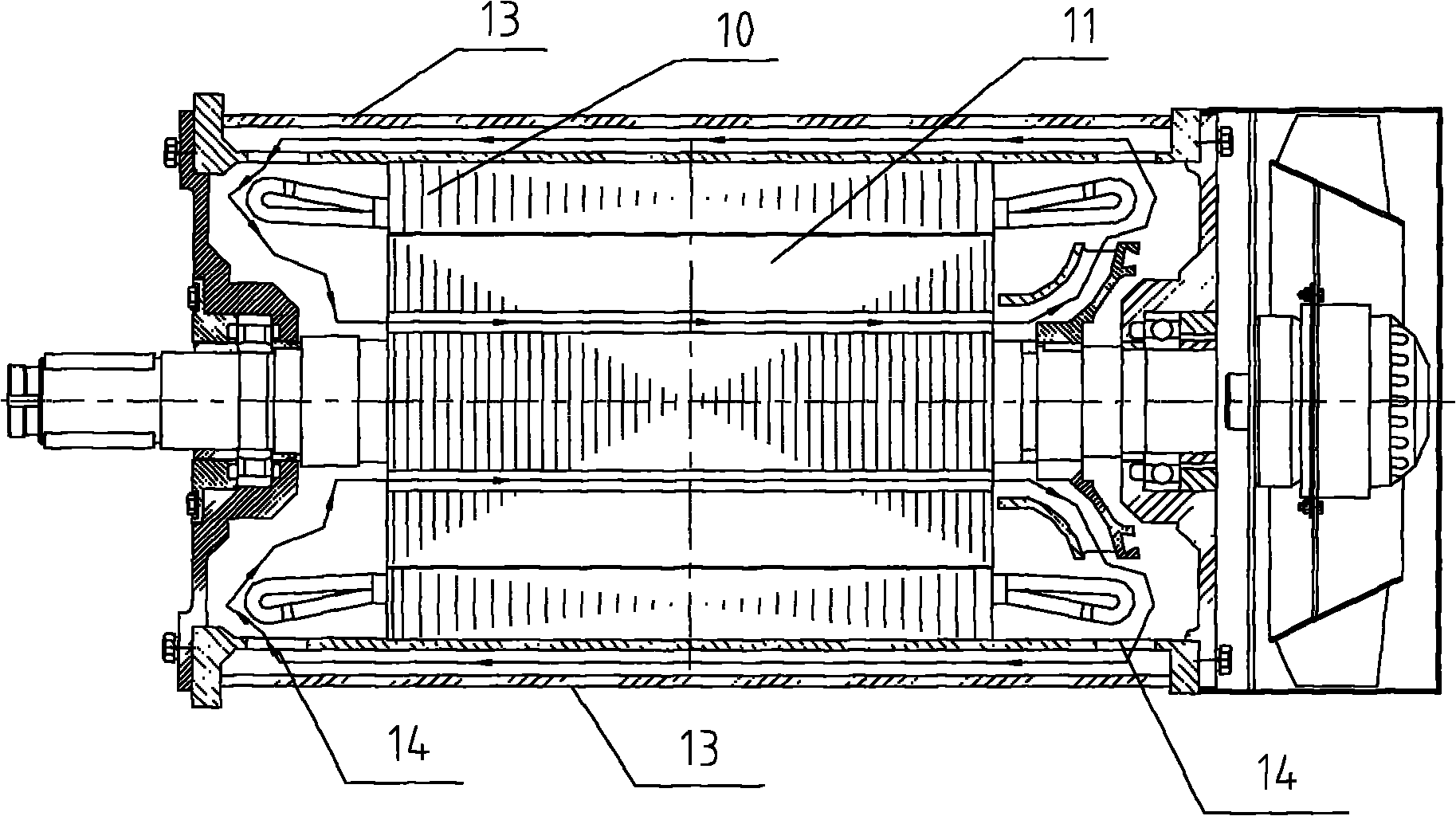

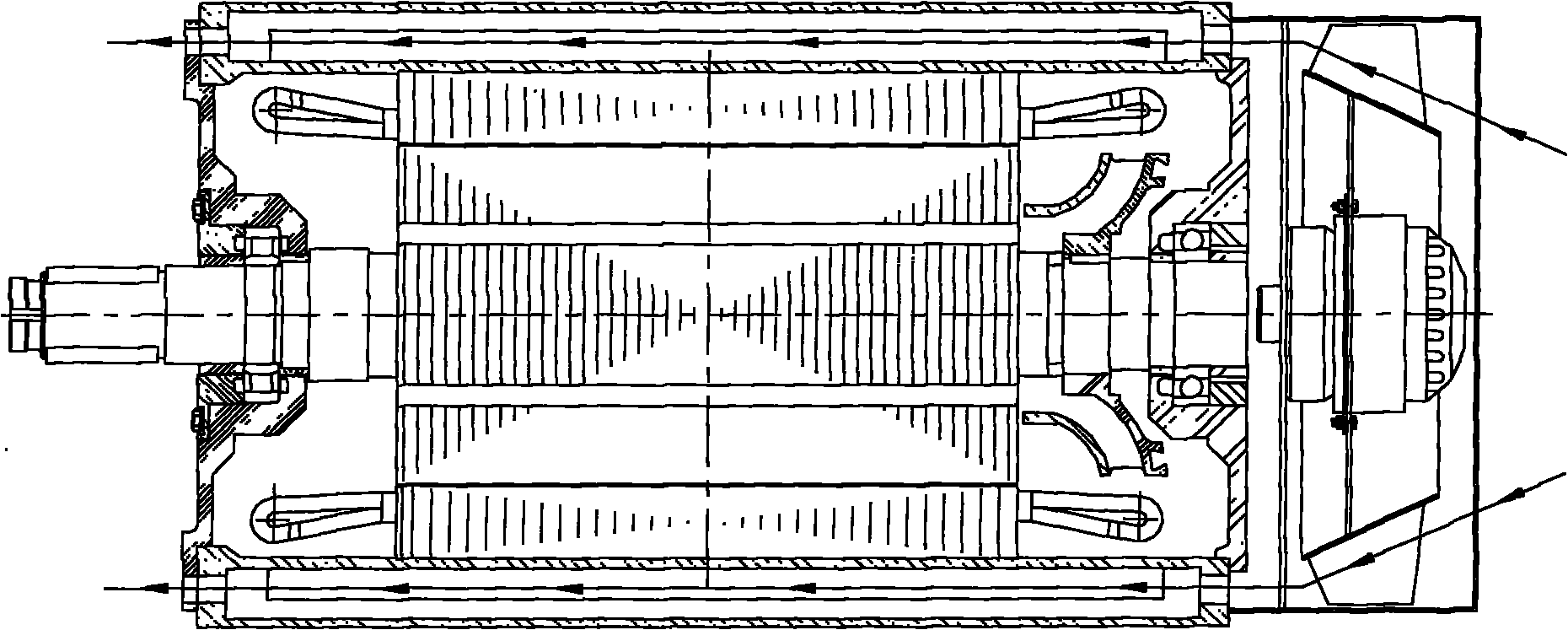

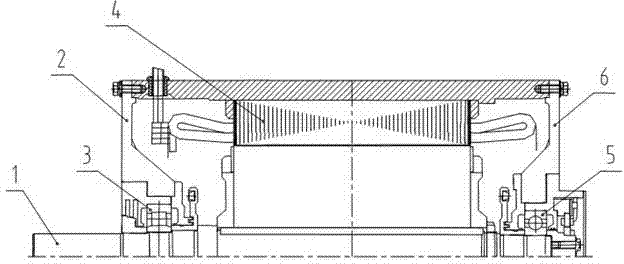

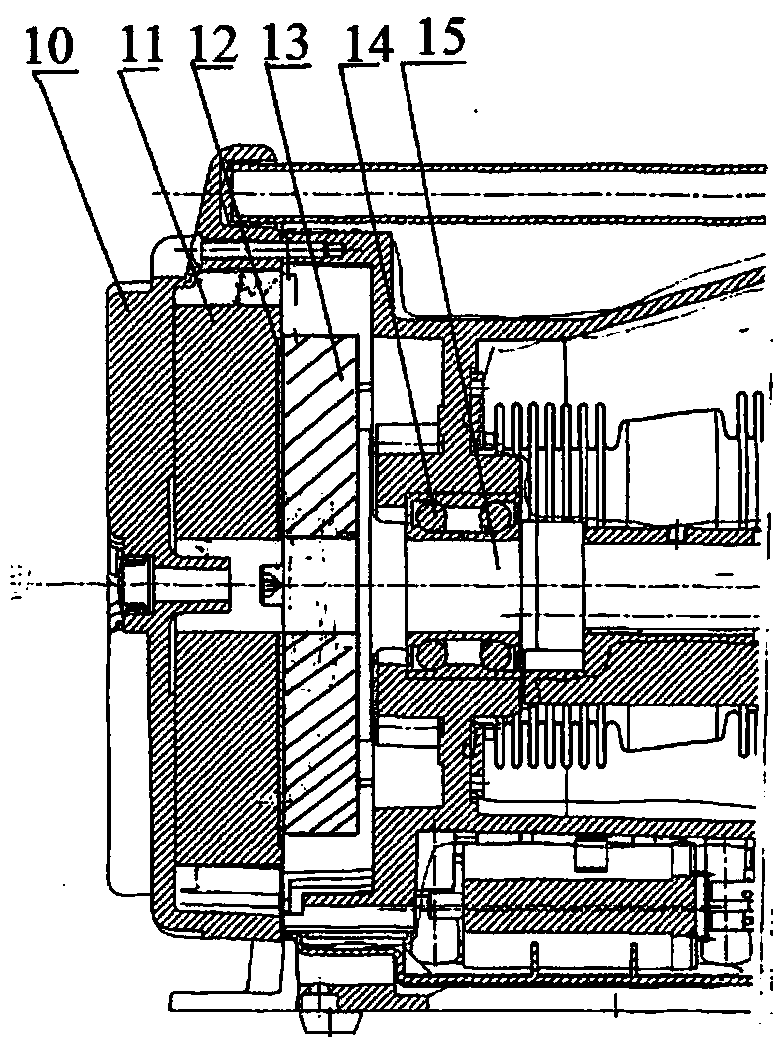

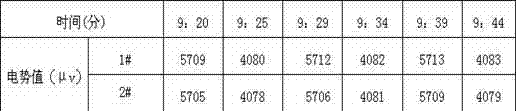

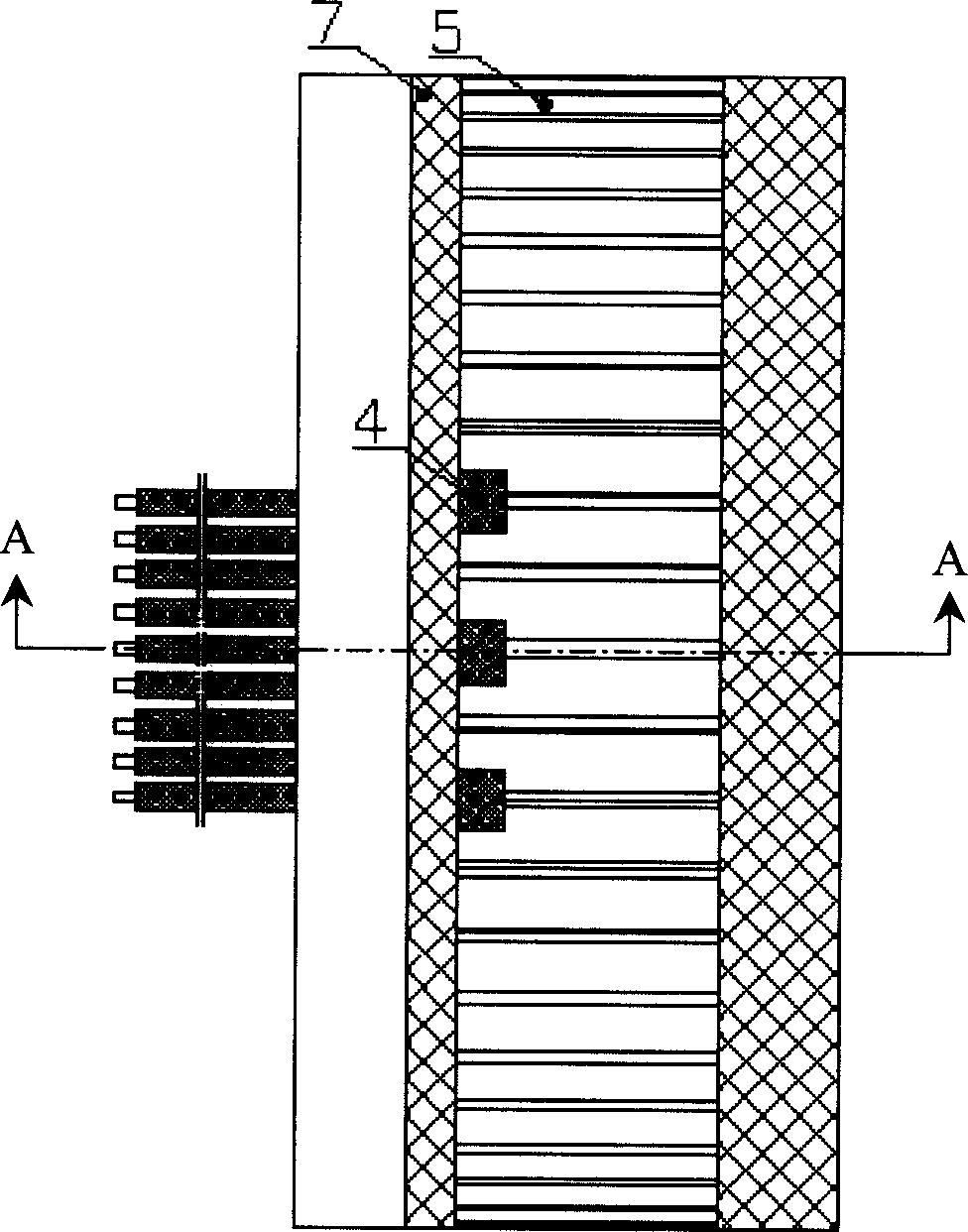

Motor with mixed-flow fan for circulating inner and outer air paths

ActiveCN101789649AUniform temperatureImprove cooling effectCooling/ventillation arrangementSupports/enclosures/casingsMixed flowLow speed

The invention relates to a power drive system of an electric automobile, in particular to a motor with a mixed-flow fan for circulating inner and outer air paths. The invention solves the problems that the traditional electronic automobile has low reliability, heat radiation at low speed and poor effect when a self-ventilation motor is used as well as large size, difficult heat radiation and low peak powder and overload capacity when a fully-closed motor is used. The power drive system comprises an enclosure, an end cover, an inner cooling air path and a rotor; a mixed flow forced cooling fan is arranged on a non-driving end shaft of the motor; an engine seat shell of the enclosure is provided with U-shaped channel steel closely covering on paired air holes to form an enclosure inner air duct; a fan cover is arranged outside the enclosure, covers U-shaped channel steel and then is welded between two flanges form an enclosure outer air duct together with the engine seat shell; and air holes are formed on the two flanges of the enclosure as well as at the position of the motor end cover, which corresponds to the enclosure outer air duct. The device can better protect the inside of the motor from being intruded by dust and rain water and can ensure heat dissipation, smaller volume and weight requirement.

Owner:CRRC YONGJI ELECTRIC CO LTD

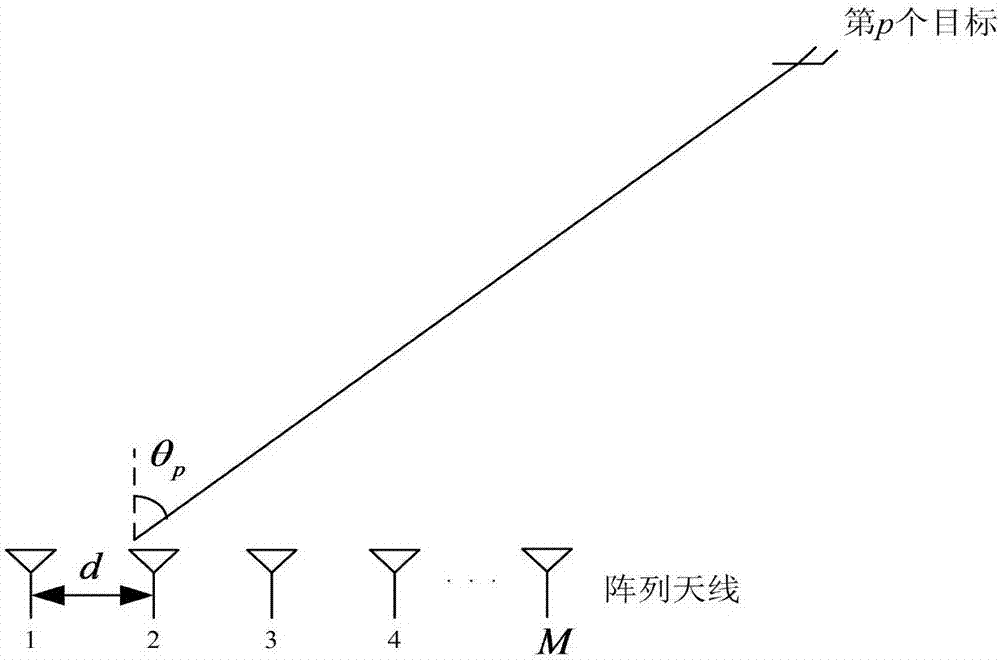

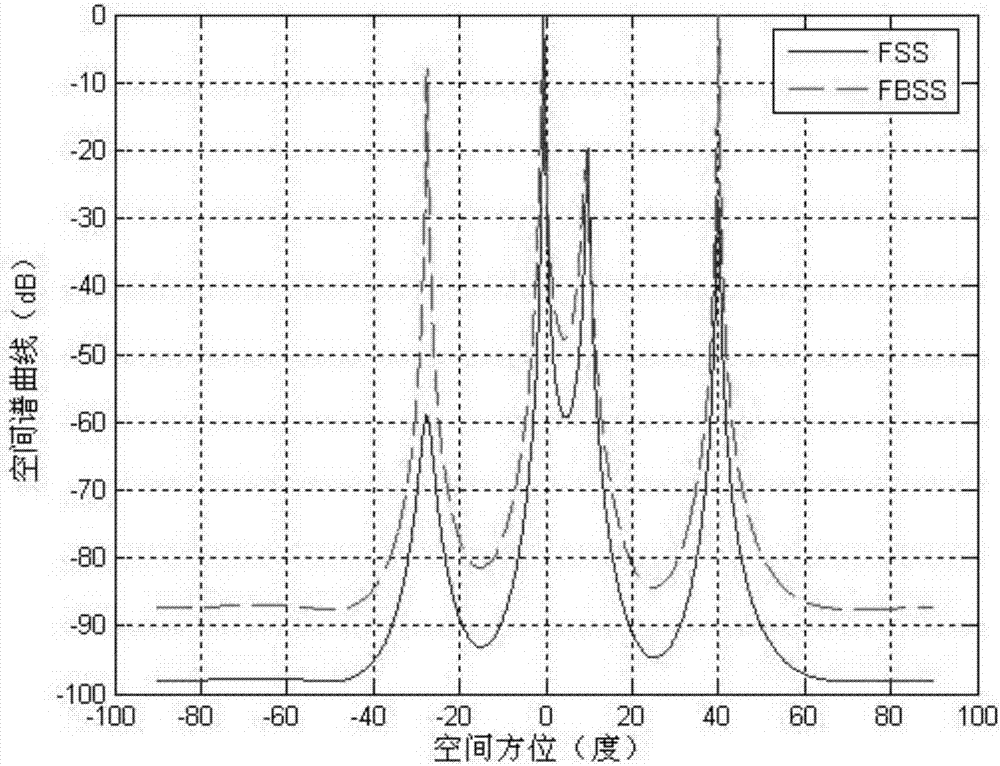

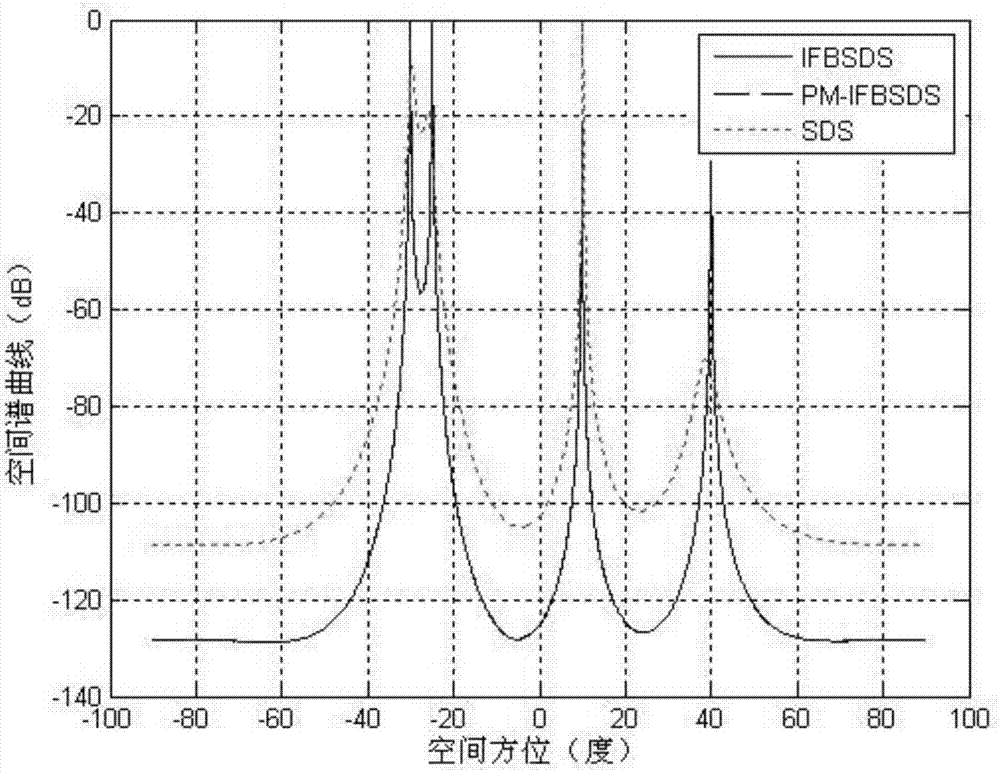

MIMO radar super-resolution direction finding algorithm of coherent signal sources under color noise background

InactiveCN106950553AStrong Color Noise SuppressionEstimated performance is goodWave based measurement systemsFast algorithmRadar

The invention relates to the field of MIMO radar (multiple-input multiple-output radar) super-resolution direction finding algorithm, discloses an MIMO radar super-resolution direction finding algorithm of coherent signal sources under the color noise background, and particularly provides an improved spatial difference smoothing (ISDS) algorithm. Besides, a fast algorithm based on a propagation operator, i.e. a PM-ISDS algorithm, is also provided based on the ISDS algorithm. Theoretical analysis and simulation prove that the algorithm has extremely high color noise suppression capacity, and the estimate performance is better than that of the common spatial smoothing algorithm so that the algorithm has great array element saving and signal source overload capacity without performing characteristic value decomposition and has low computational burden.

Owner:XIDIAN UNIV

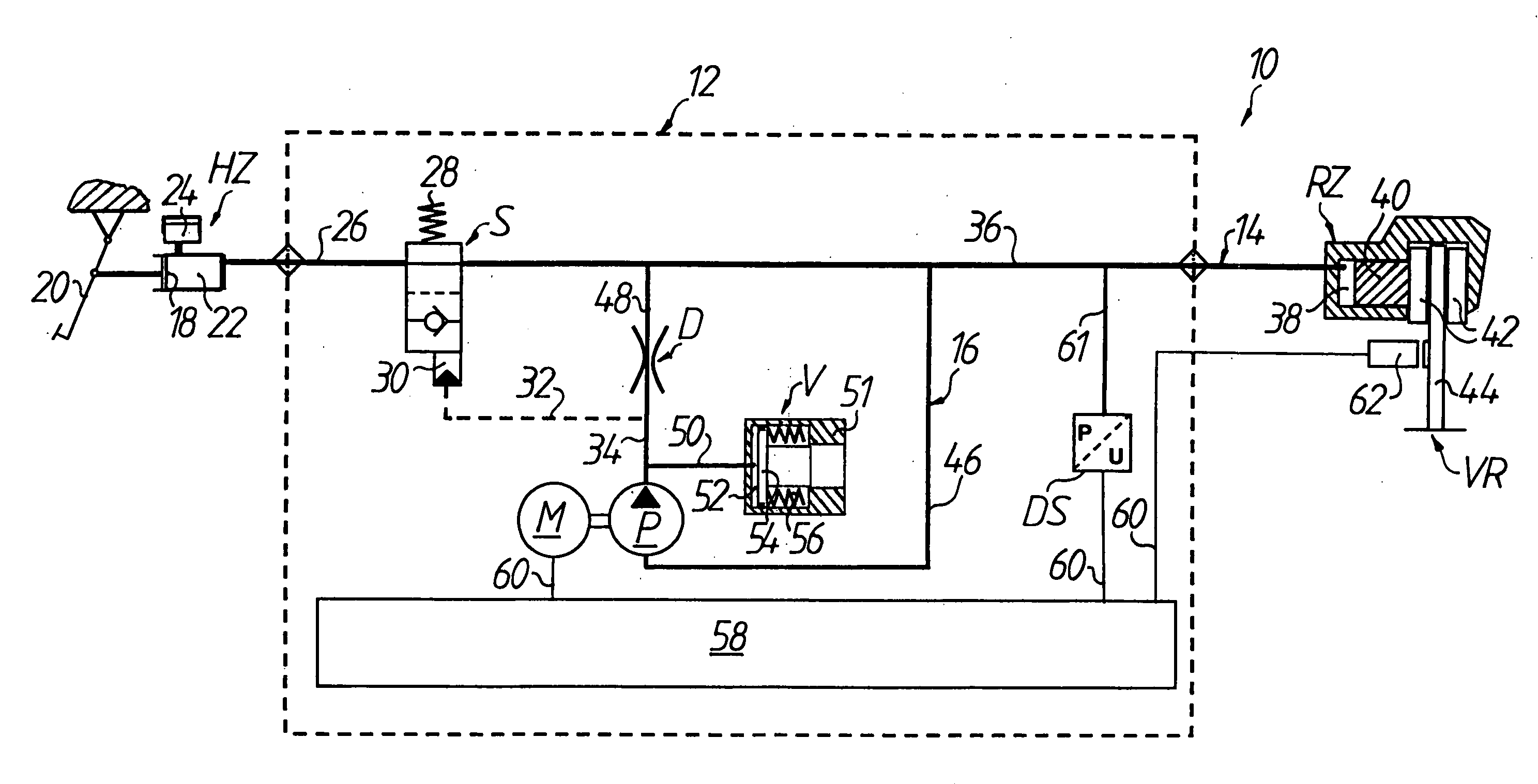

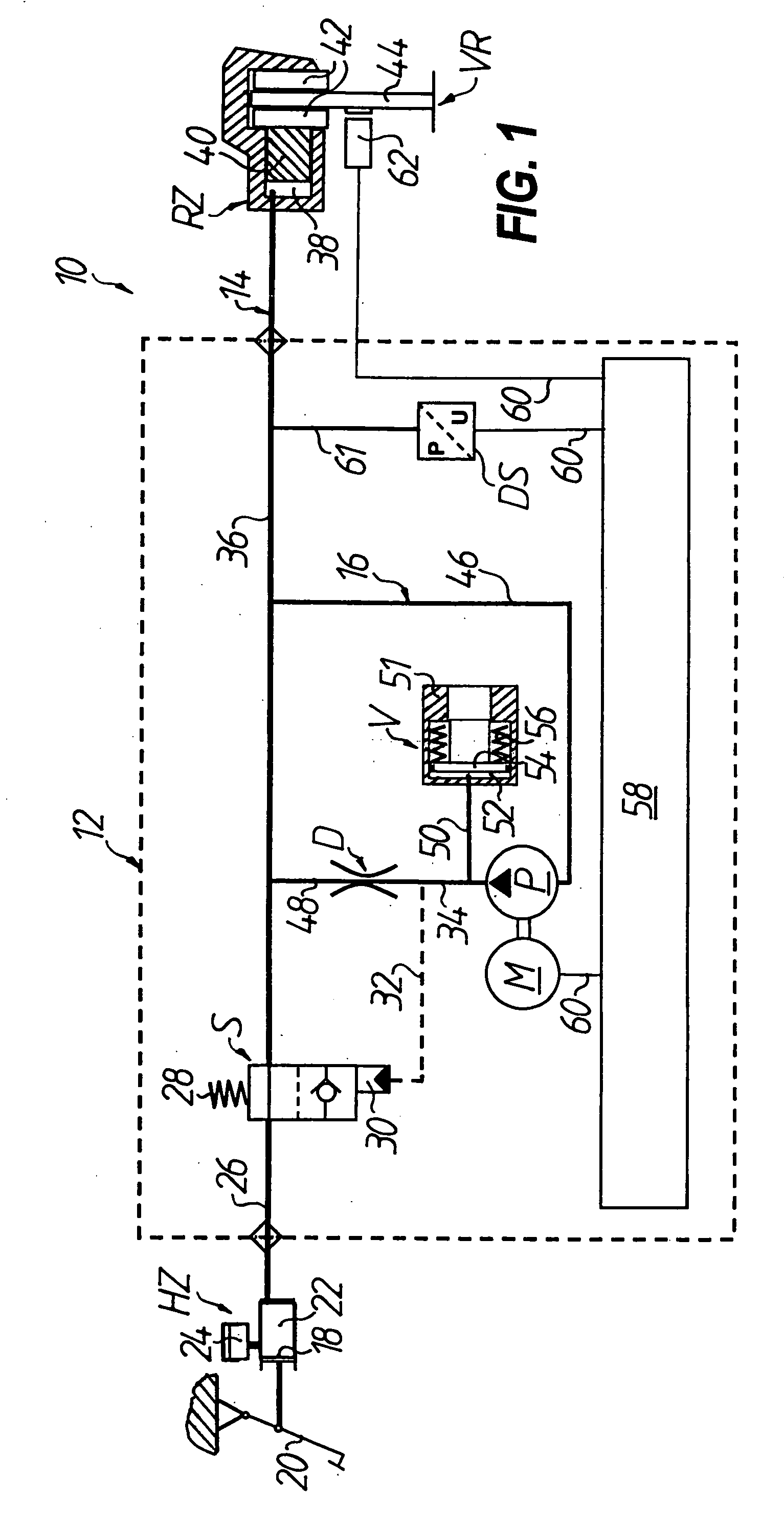

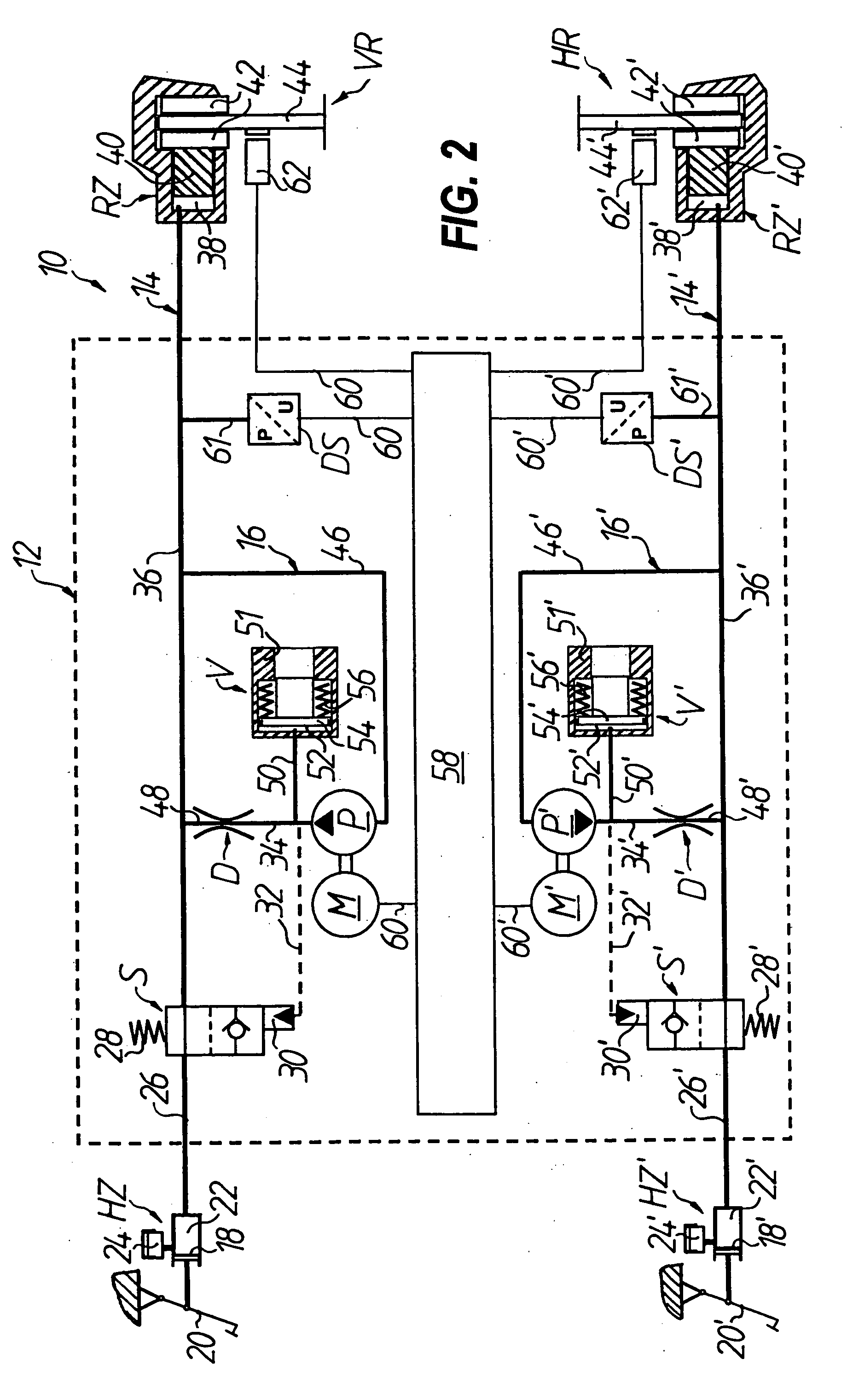

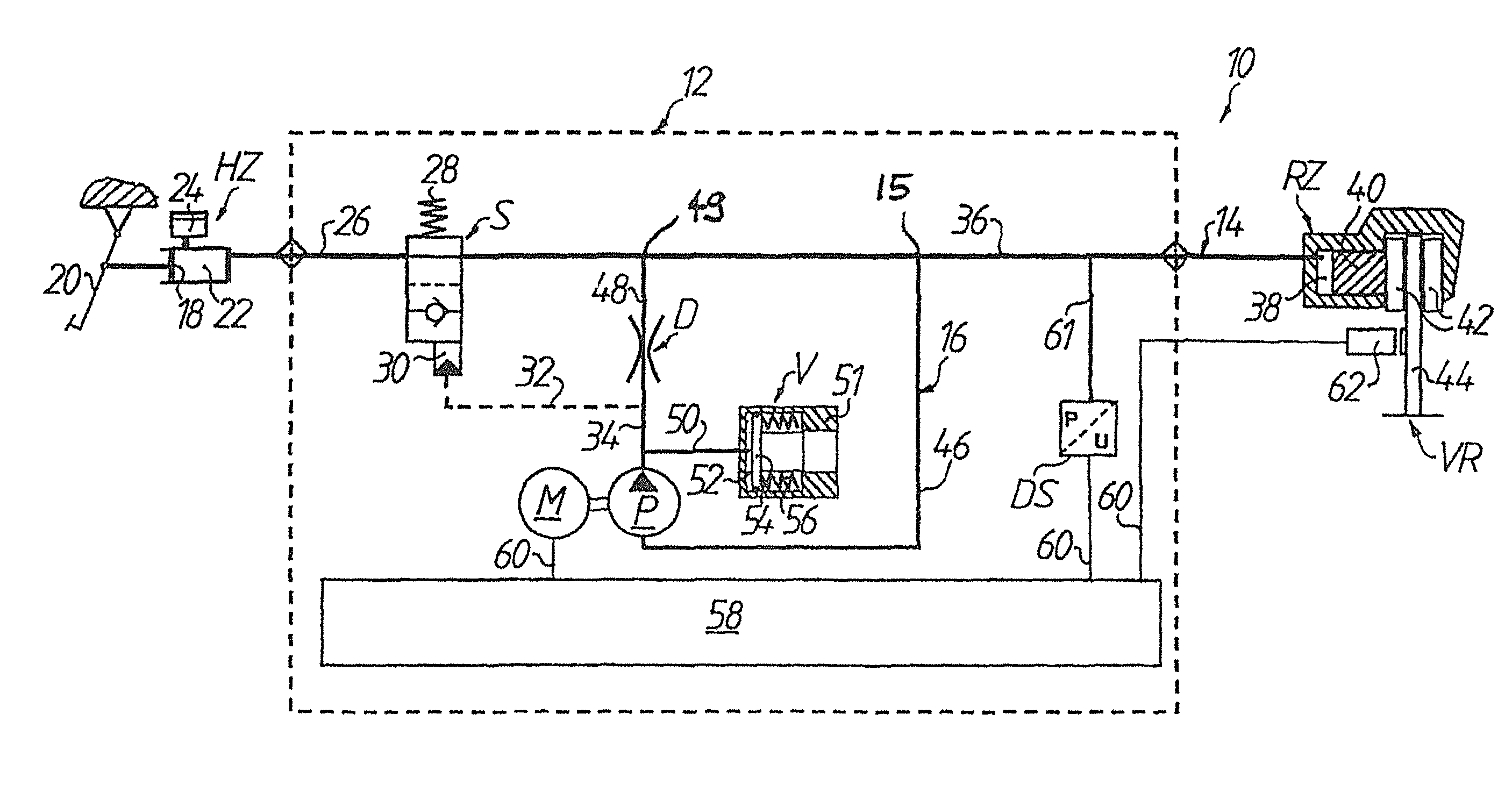

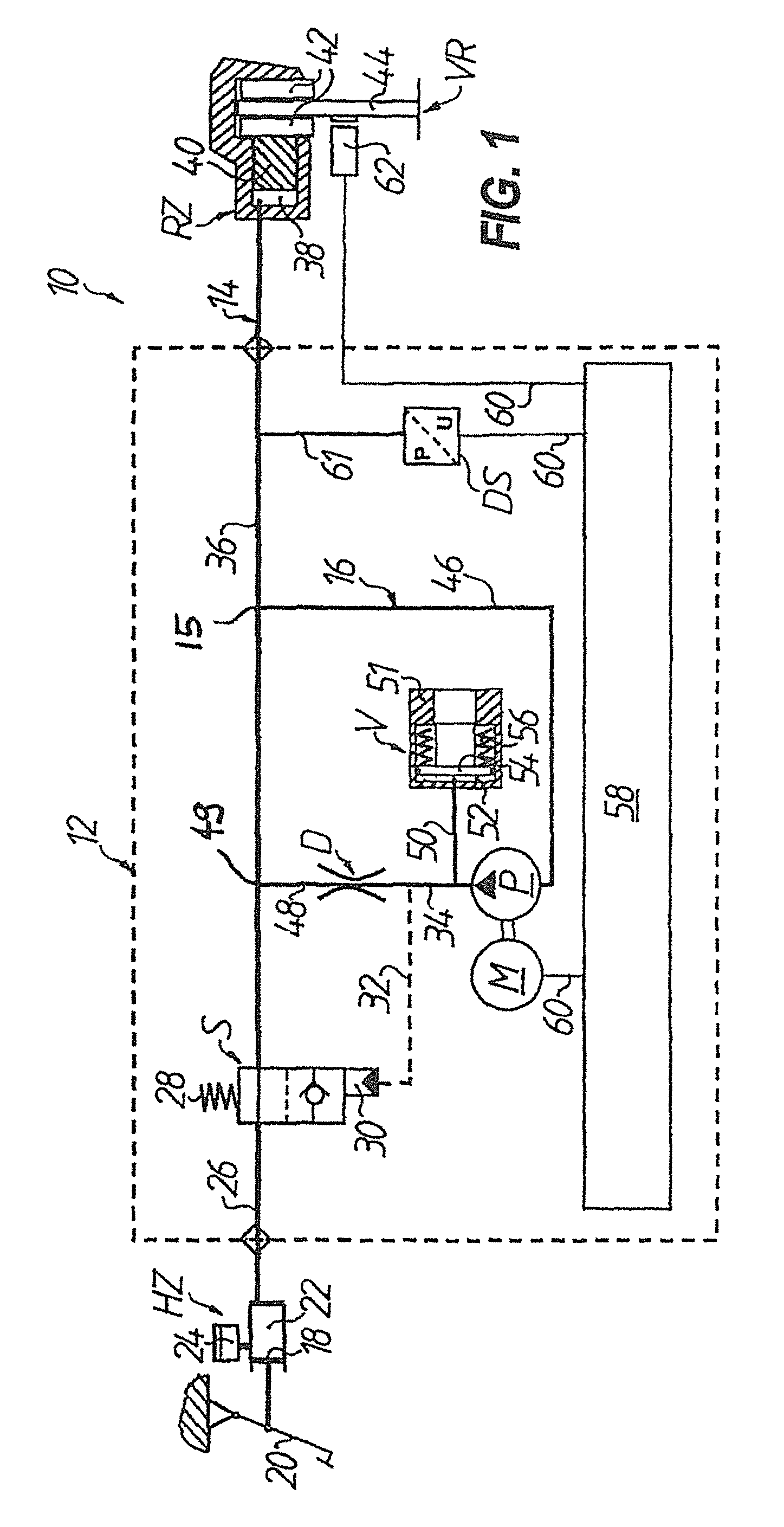

Anti-lock hydraulic braking system, in particular for motorized two-wheel vehicles

InactiveUS20080246334A1Simpler and less-expensiveDisruptive effectBraking action transmissionBraking systemBrake pressure

An anti-lock hydraulic braking system has a wheel brake circuit with a main brake cylinder, wheel brake cylinder and switching valve, and an auxiliary pressure circuit, connected in parallel between the switching valve and wheel brake cylinder on the wheel brake circuit. With ABS control, the switching valve can be switched from a basic position, where it hydraulically connects the main brake cylinder and wheel brake cylinder, to a switched position where it prevents a build-up of braking pressure on the wheel brake cylinder via the main brake cylinder, while the braking pressure on the wheel brake cylinder can be modulated by the auxiliary pressure circuit.

Owner:FTE AUTOMOTIVE GMBH & CO KG

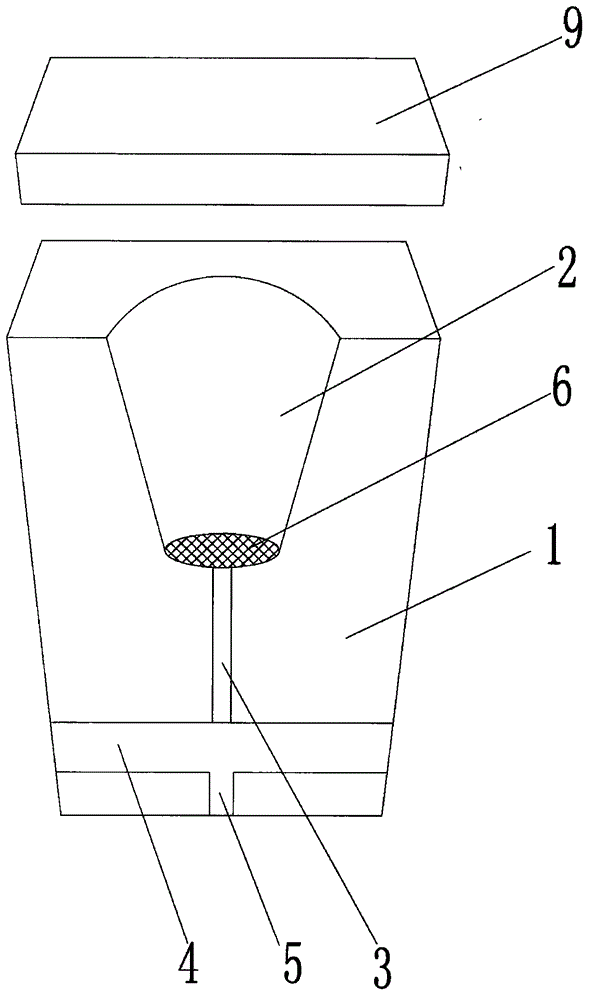

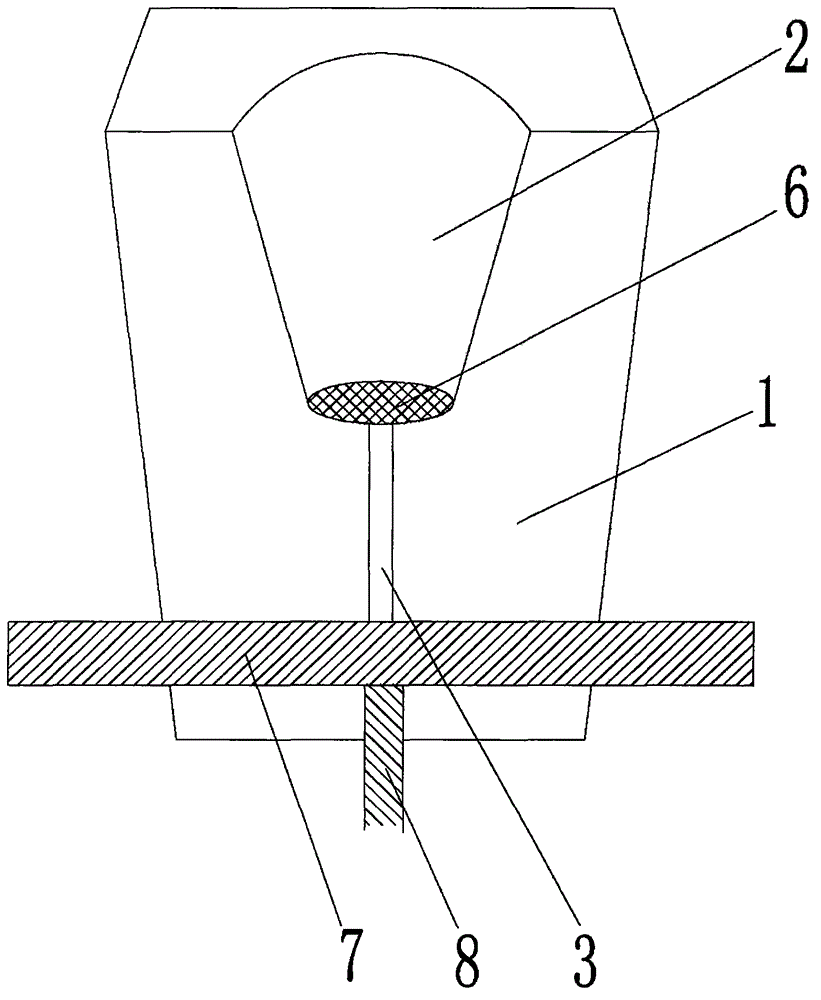

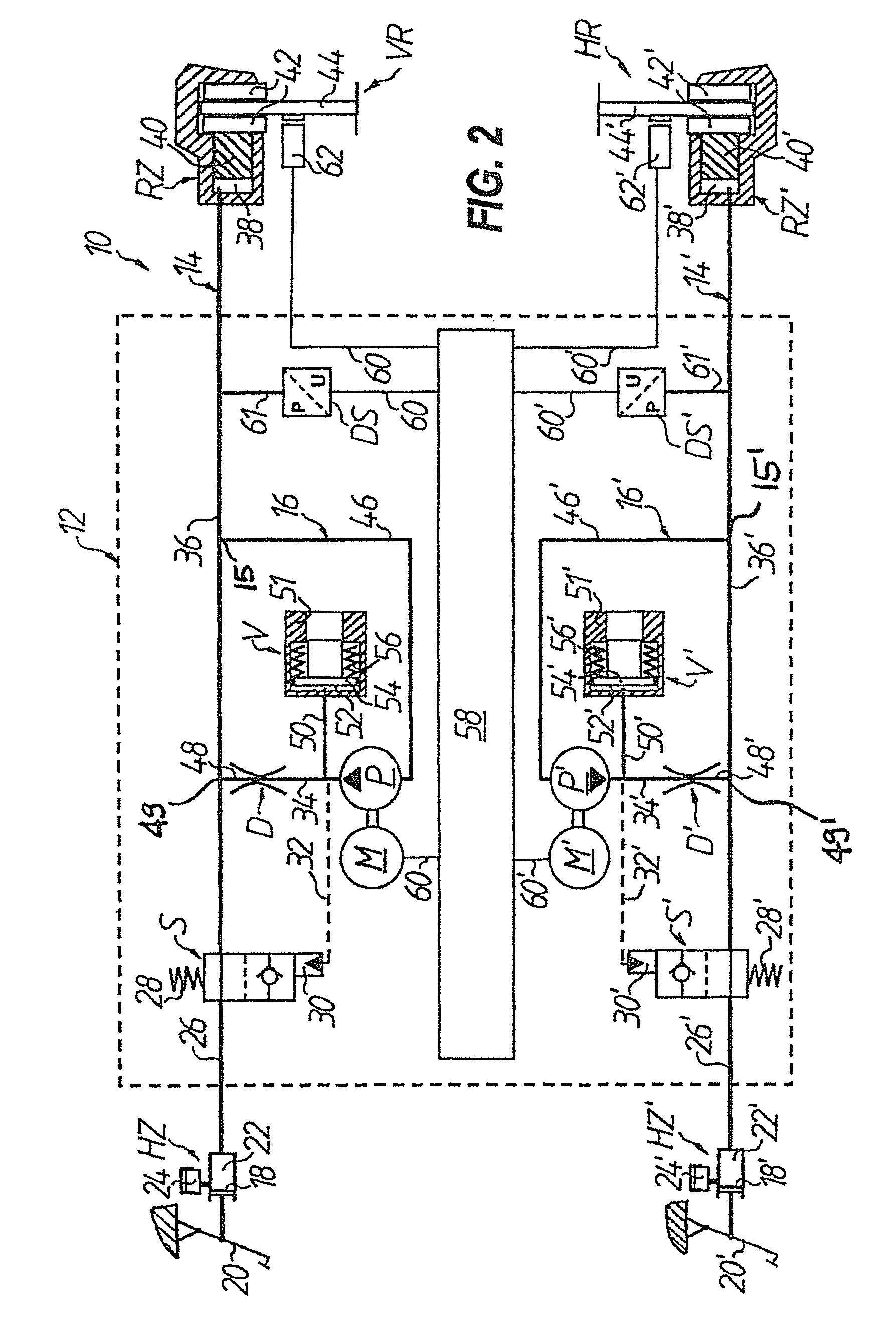

Die for exothermic welding of grounding grid and welding method

InactiveCN104625513ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesExothermic weldingGrounding grid

The invention relates to a die for exothermic welding of a grounding grid and a welding method. The welding method includes the process steps: cleaning a copper bar, a grounding rod and a die body and placing the copper bar and the grounding rod to be welded into a copper bar placing cavity and a grounding rod placing cavity respectively; clamping a left piece and a right piece of the die body, laying down a supporting piece, sealing the top of a die cavity and stopping exothermic welding flux before reaction from flowing into the die cavity; pouring the exothermic welding flux into a welding powder filling area, spreading initial pyrophoric powder and covering a die cover; igniting the pyrophoric powder by a firing gun and performing exothermic reaction of the exothermic welding flux in the die; opening the die after hot melting reaction of the exothermic welding flux for 10-20 seconds; taking out the copper bar and the grounding rod which are welded, and removing molten slag. The shortcomings of welding slag, easiness in oxidation, low connecting strength, easiness in corrosion, small contact area, large contact resistance and the like in traditional welding such as electric welding and braze welding, additional energy and power are omitted, and the welding method is a simple, high-efficiency and high-quality metal connecting process.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD

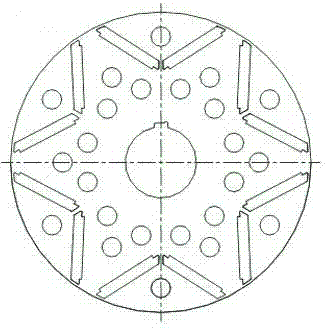

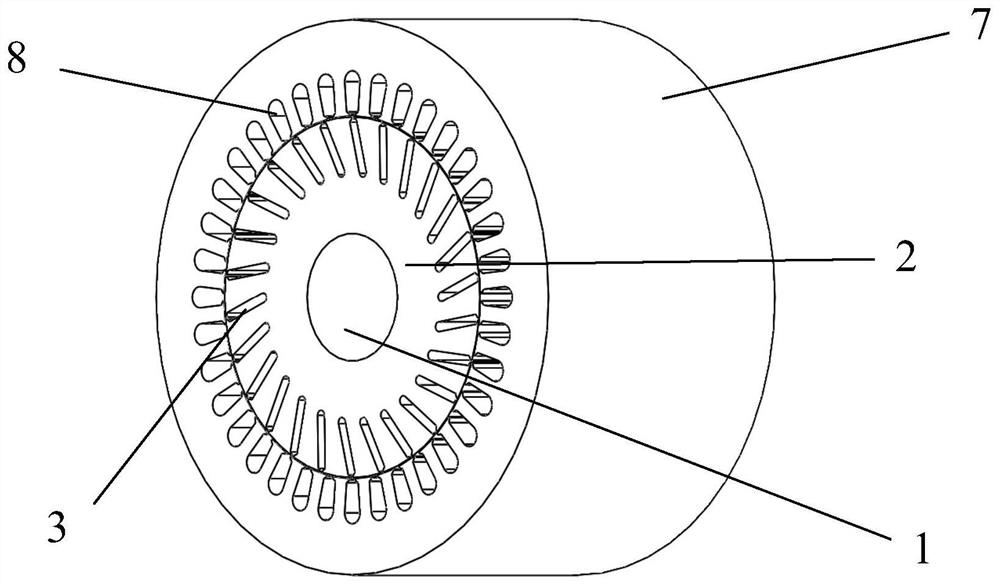

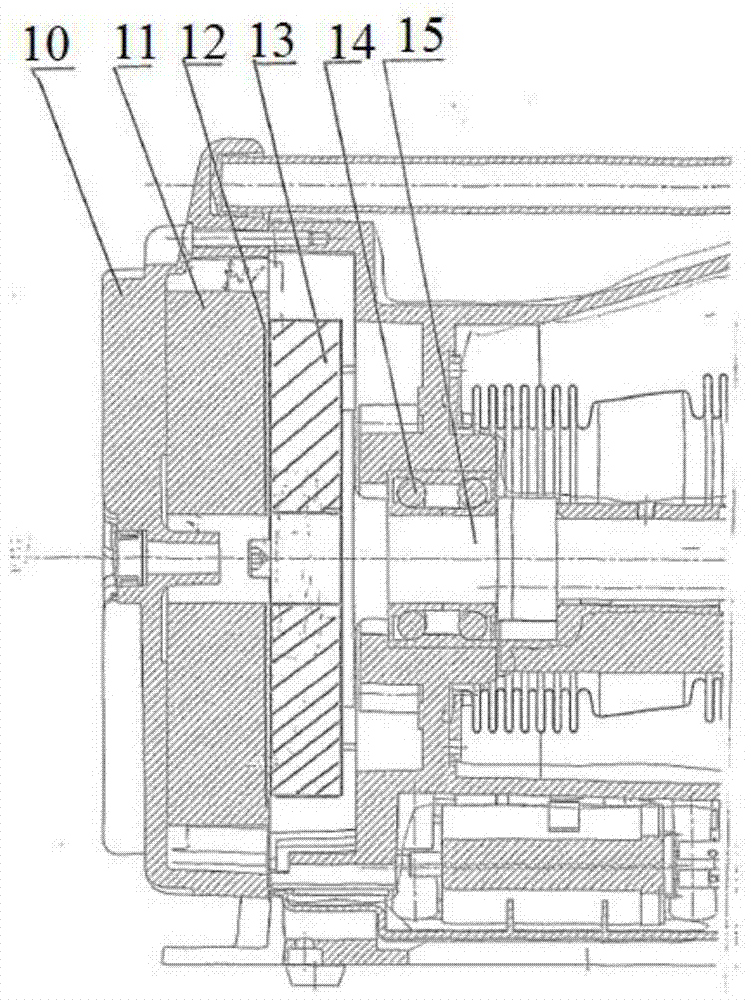

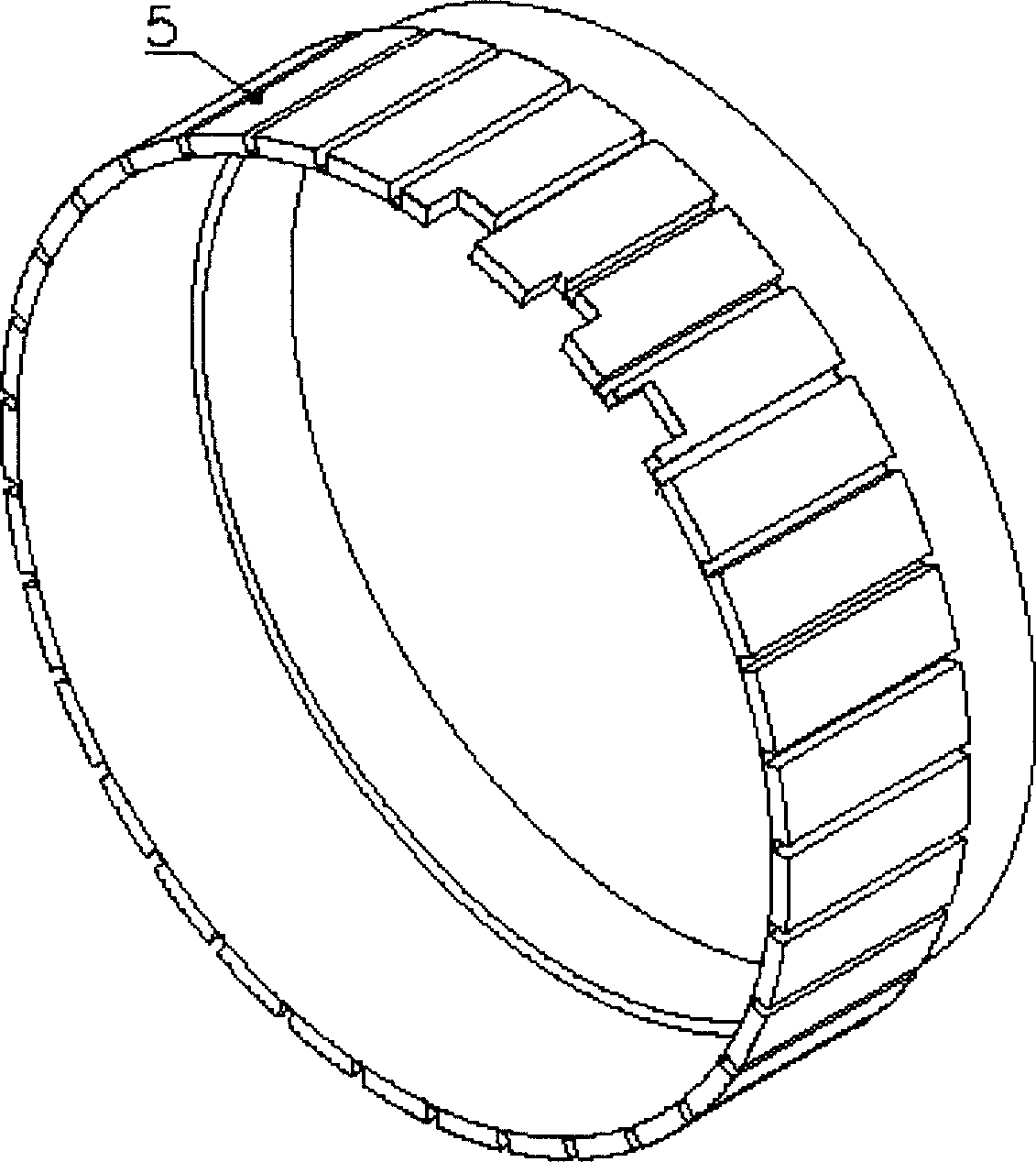

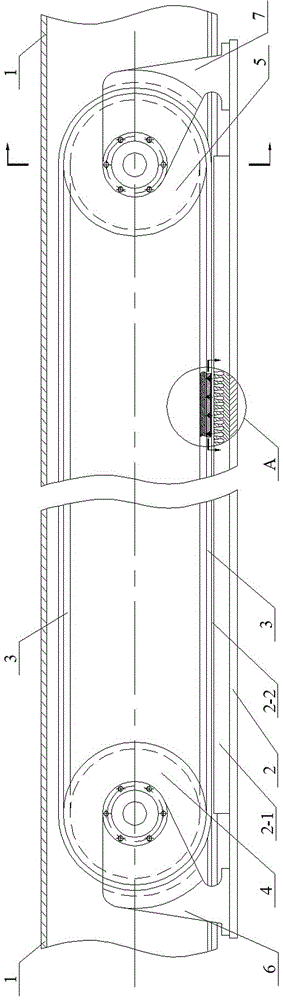

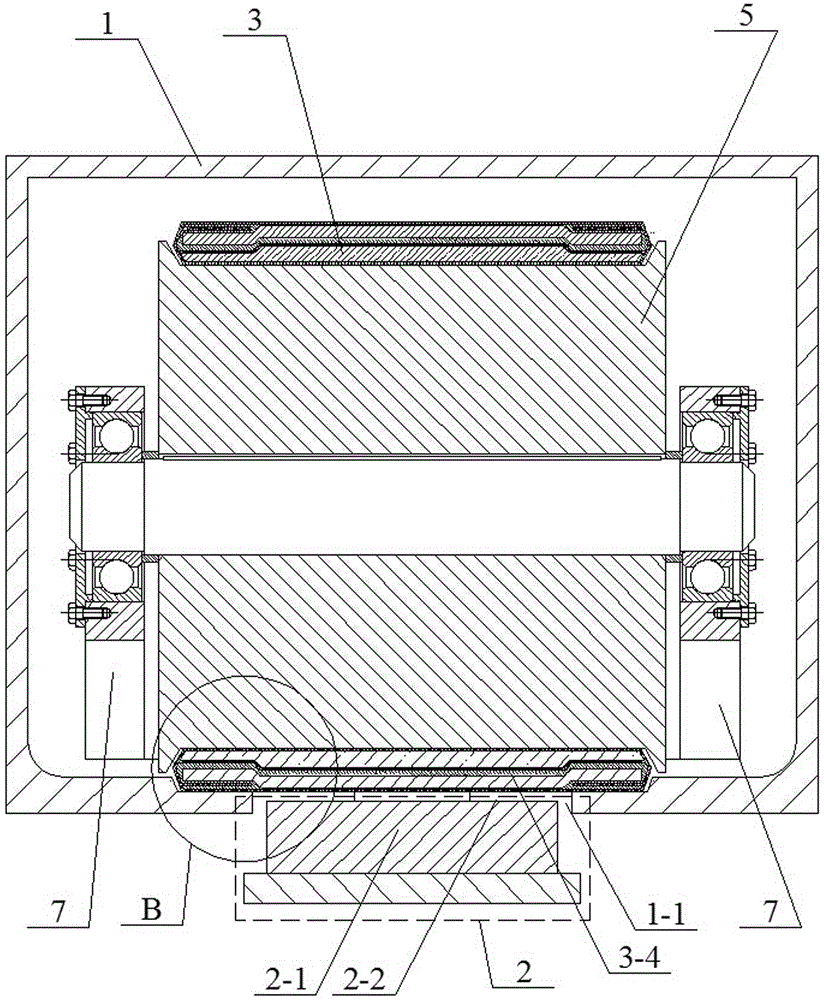

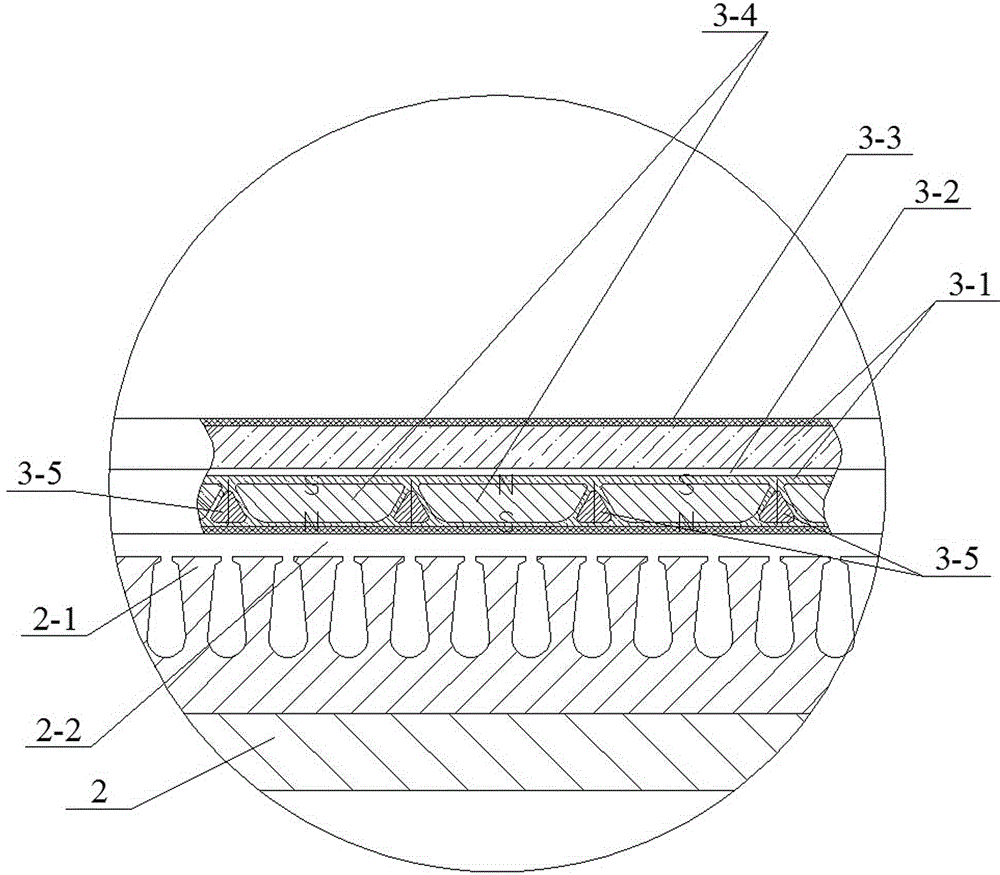

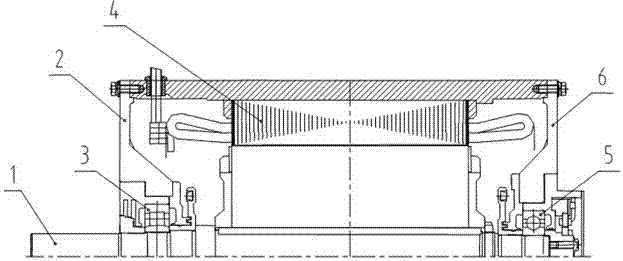

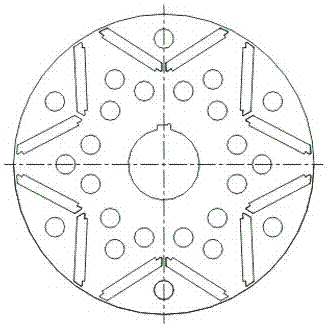

Permanent-magnet synchronous traction motor for motor train

ActiveCN104767337AImprove efficiencyIncrease powerSynchronous machine detailsMagnetic circuit rotating partsPunchingPermanent magnet synchronous motor

The invention relates to a motor, in particular to a permanent-magnet synchronous traction motor for a motor train. The permanent-magnet synchronous traction motor for the motor train solves the problem that an existing permanent-magnet synchronous motor is not suitable for being directly used as a permanent-magnet synchronous traction motor for a motor train due to structure defects. The motor adopts a novel rotor magnetic circuit structure punching plate, a high-integration compact type rotor structure, a detachable connecting box structure and a lead structure. A connecting box can be conveniently disassembled so that the motor can be installed easily. A U-shaped magnetic circuit permanent magnet structure of an inner rotor is adopted, the magnetic separation bridge and circular bead design is added, and therefore the start and overload capacity of the motor can be improved. A rotor pressing ring at the driving end integrates rotor core pressing, permanent magnet end face pressing, rotor dynamic balancing and an inner seal ring labyrinth seal structure into a whole, the advantages that the structure is compact, the axial occupied space is small, and the installation is convenient are achieved, and the motor can be widely applied in the field of locomotive trains. According to the research, development and the operation of the permanent-magnet synchronous traction motor for the motor train, realistic bases are supplied for the permanent-magnet motor to research and develop a permanent-magnet traction motor structure with higher power, higher rotation speed and higher power density.

Owner:CRRC YONGJI ELECTRIC CO LTD

Variable frequency speed regulating disk type motor and vacuum pump

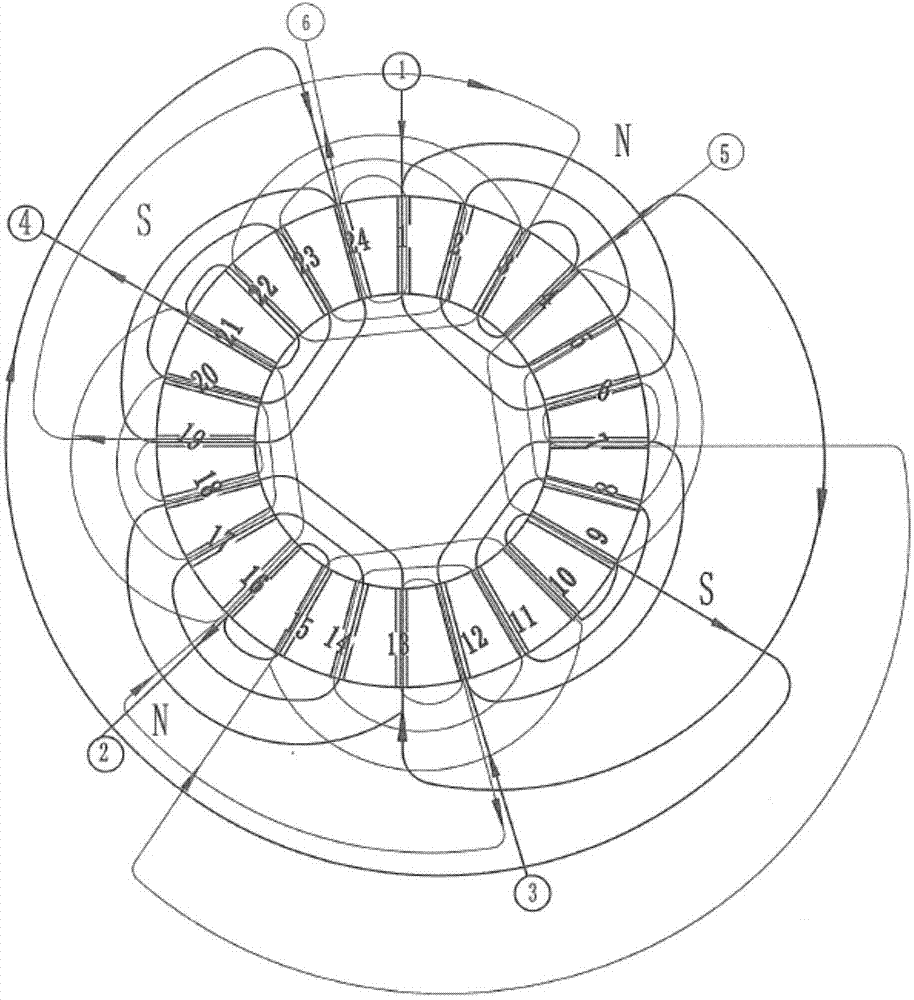

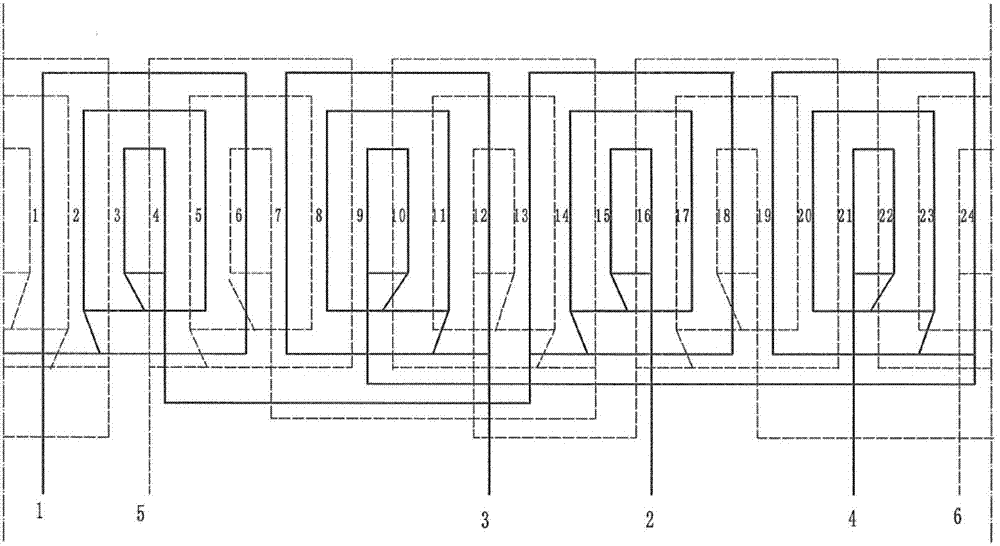

ActiveCN103457366AReduce volumeRealize the integration of machine and pumpMagnetic circuit stationary partsWindings conductor shape/form/constructionCapacitanceLow voltage

The invention provides a variable frequency speed regulating disk type motor which uses sinusoidal windings and is in a double-layered type. Through interactive compensation action of two coils in each electrode of two main windings, the electrodes are sequentially connected, a magnetic filed is made to be distributed more evenly, the waveform is close to the sine wave, and declining of torque can not happen any more at a low rotating speed. Meanwhile, in the starting process, an auxiliary winding is connected with an operating capacitor and a starting capacitor, in the operating process, the auxiliary winding and the operating capacitor are connected, and startability and overload capacity are guaranteed. Meanwhile, through switching of the connecting mode of a high voltage and a low voltage, when the motor works in the high voltage of 200V-240V, the first main winding and the second main winding are in parallel connection with an auxiliary winding circuit after being in series connection, and when the motor works in the low voltage of 100V-120V, the first main winding, the second main winding and the auxiliary winding circuit are in mutual parallel connection. The variable frequency speed regulating disk type motor meets the operating demands in different rotating speed range under a general voltage condition in the global range. In addition, integration of the motor and a pump is achieved when the variable frequency speed regulating disk type motor is applied to a vacuum pump.

Owner:北京富特盘式电机有限公司

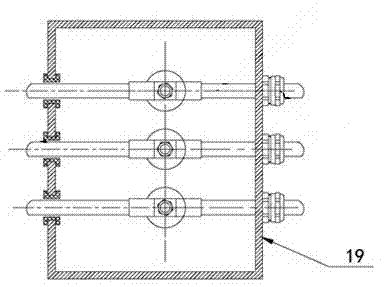

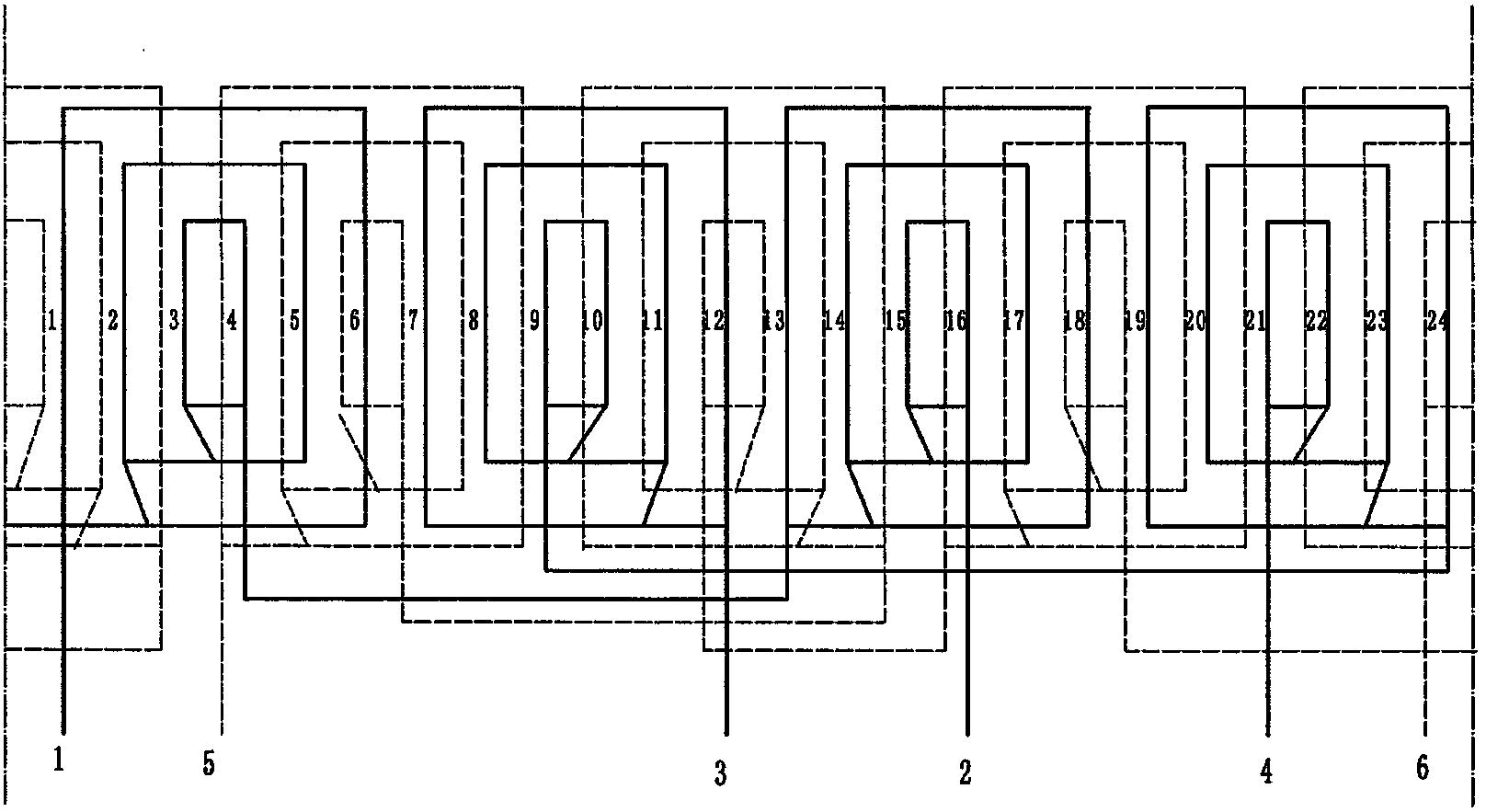

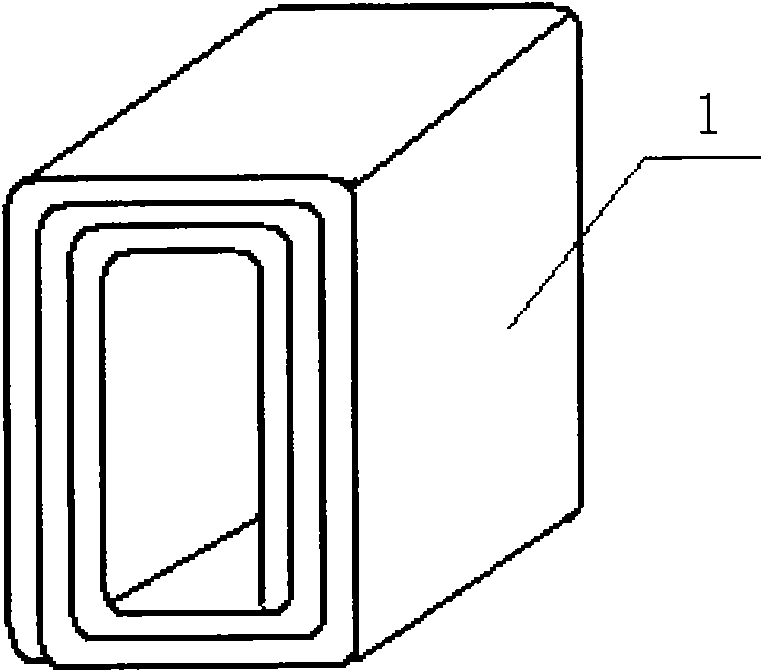

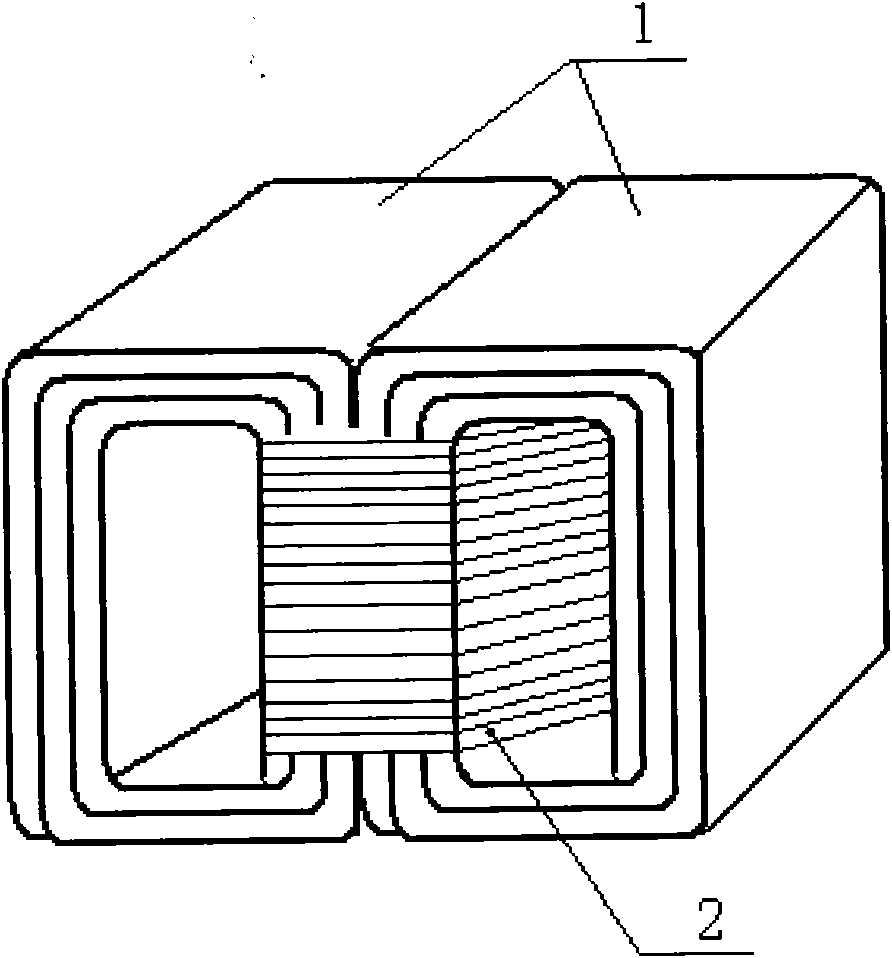

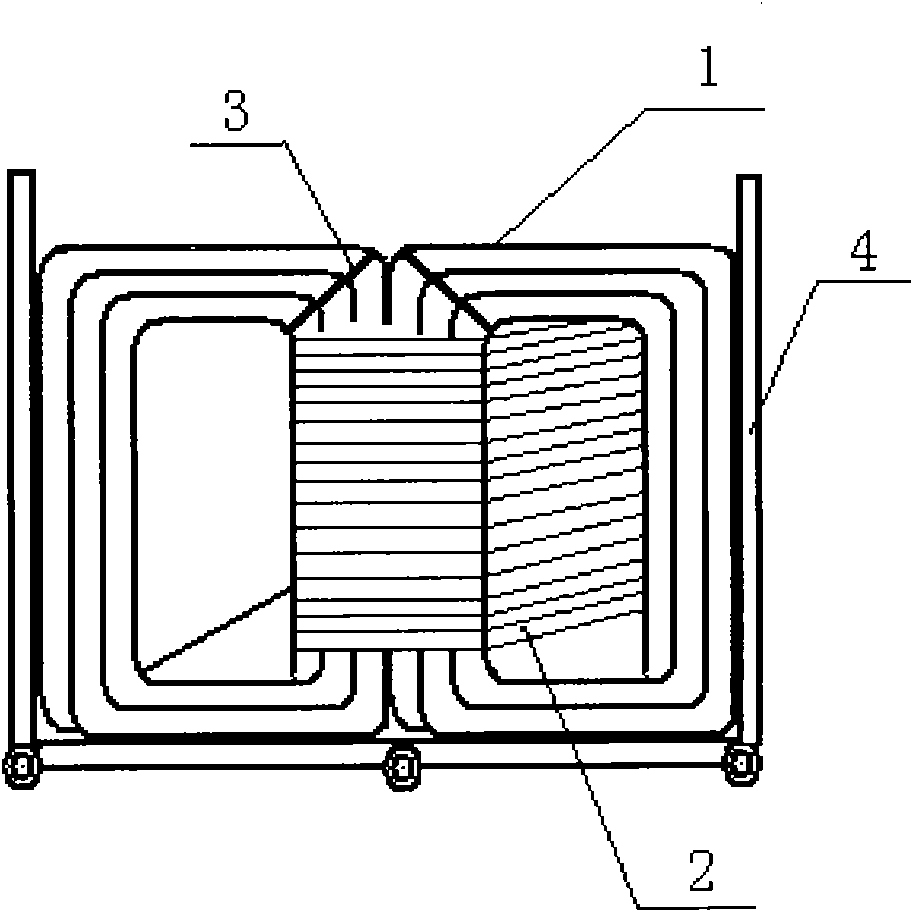

Iron winding core for shell transformer and method

InactiveCN101819859ALower impedanceImprove cooling effectTransformers/inductances magnetic coresInductances/transformers/magnets manufactureLow noiseEpoxy

The invention discloses an iron winding core for a shell transformer and a manufacturing method. The iron core has rectangular iron winding cores, and the number of the iron winding cores is two; the two iron winding cores are bond together by using a binding belt and cured by using epoxy resin, and staggered windings are sleeved on the periphery of the binding belt; and a notch is formed above the binding belt on the two rectangular iron winding cores respectively, and the two notches are distributed symmetrically. The iron winding core for the shell transformer has the advantages of good maintainability, low reluctance, great reduction of no-load loss and extremely low noise; the iron winding core is mechanically wound so as to save the labor force and improve the production efficiency; the iron winding core is integral, so the iron winding core is easy to fix and wedge; and the iron winding core has high space factor and saves materials.

Owner:威海华通开关设备有限公司

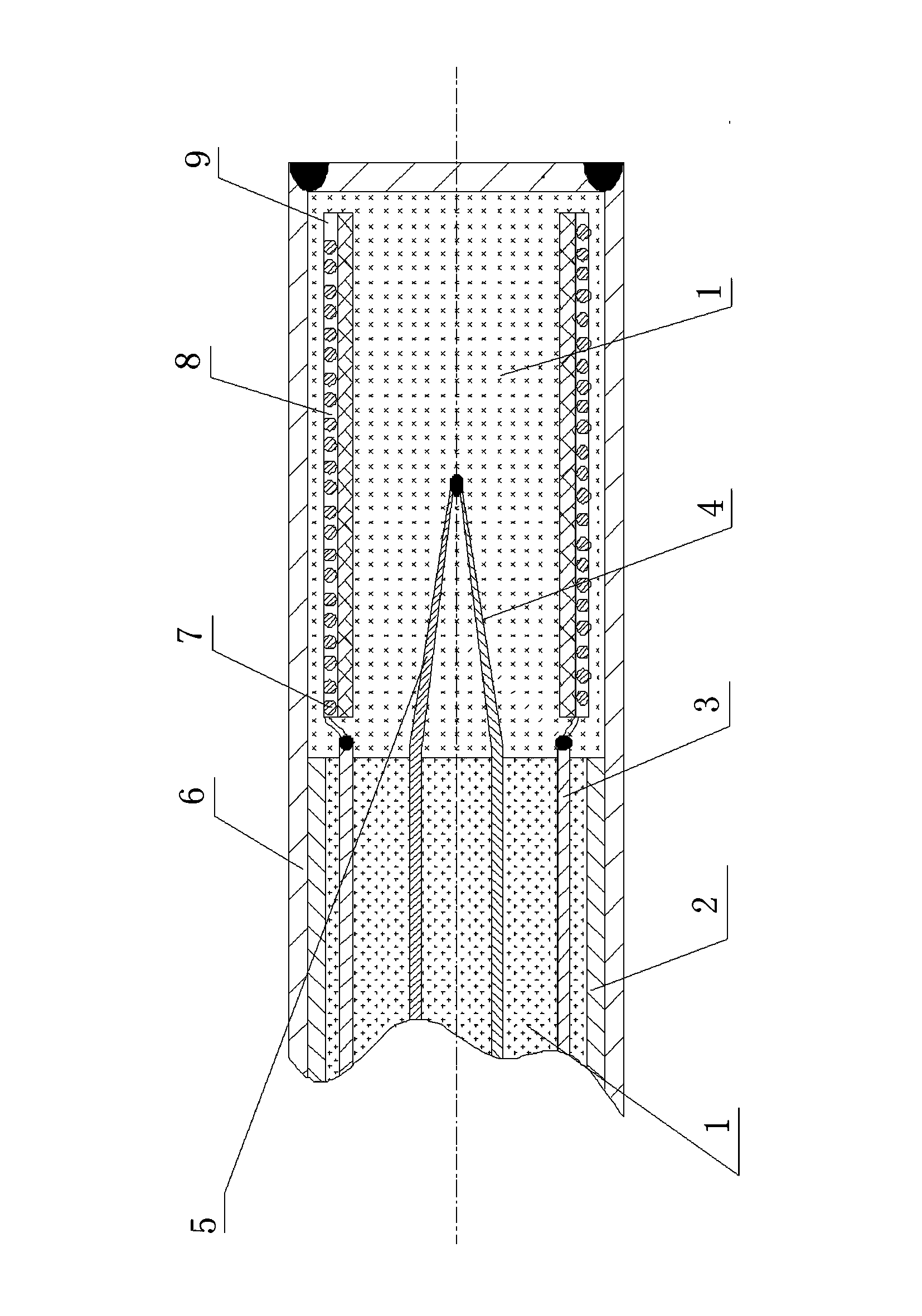

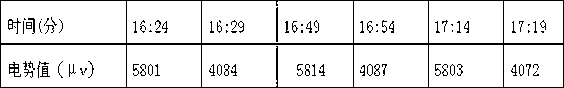

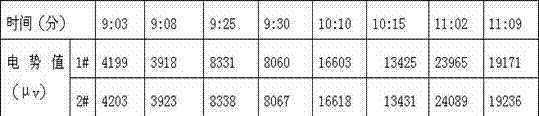

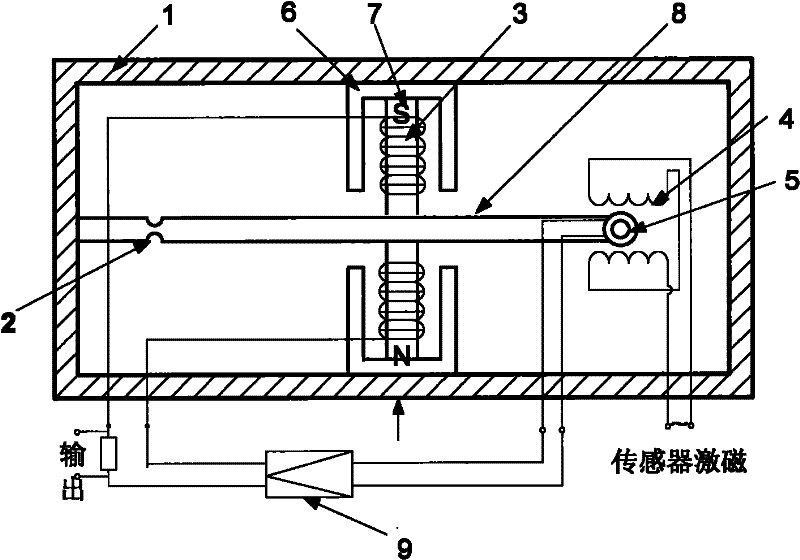

Preparation method of heating type thermocouple liquid level measurement sensor

ActiveCN103162768AImprove accuracyImprove reliabilityLevel indicators by physical variable measurementLiquid level measurementPhysical chemistry

The invention relates to a preparation method of a heating type thermocouple liquid level measurement sensor. According to the preparation method of the heating type thermocouple liquid level measurement sensor, prepared heating elements and prepared armored cables are assembled together and fully sealed so that the heating type thermocouple liquid level measurement sensor can be obtained. The heating type thermocouple liquid level measurement sensor prepared through the method has the advantages of being capable of accurately judging a liquid-gas (vapor) interface under the conditions of high temperature and high pressure, good in reproducibility and high in resolution, capable of meeting requirements of an overload test, capable of accurately judging the liquid-gas (vapor) interface under severe environments of high temperature and high pressure, simple in process and good in uniformity of products.

Owner:CHONGQING MATERIALS RES INST

Paint-dipping drying technique for dry-type three-phase combined transformer

The name of the invention is paint dipping and drying technology of a three-phase combined transformer. The invention relates to the dry-typed three-phase combined transformer, in particular to the paint dipping and drying technology of the three-phase combined transformer. The technology can solve the problems of small overload capacity, easy explosion, heavy weight and inconvenient installation of the known epoxy resin cast dry-typed combined transformer. The technology is the paint dipping and drying technology of a voltage transformer coil and is completed by three times; in the first time, the coil is well winded for paint dipping; in the second time, a secondary coil is well placed for paint dipping after wrapping a foot loop; in the third time, the paint dipping is carried out after well winding an outer insulation; the three times of the paint dipping and drying technology process and the paint dipping and drying technology process of a current transformer coil are as follows: (1) pre-drying of a white body; (2) vacuum dewetting; (3) paint dipping; (4) returning of paint; (5) returning of residual paint; (6) cleaning; (7) returning of a cleaning agent; (8) drying. The paint dipping and drying technology has higher dynamic and thermal stability, fire retardance, environmental protection, safety, low loss, good thermal radiation, great overload capacity, light weight, convenient transportation and installation and free maintenance.

Owner:王立诚

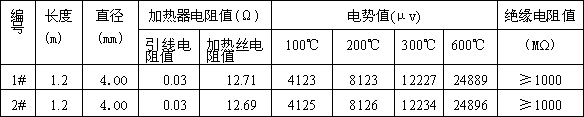

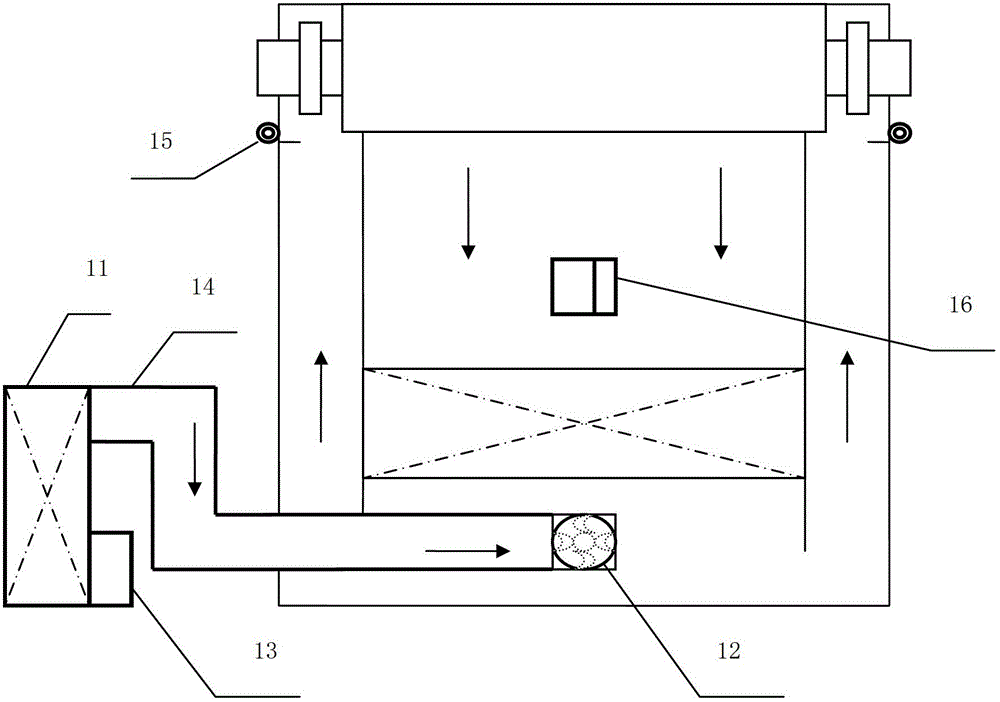

Supplementary cooling device and supplementary cooling method of air-cooling power generator

InactiveCN102751817AImprove cooling effectHigh overload performanceCooling/ventillation arrangementStator coilCooling power

The invention discloses a supplementary cooling device and a supplementary cooling method of an air-cooling power generator, which are capable of enabling the air-cooling power generator to generate power with full load at high-temperature weather. The device comprises an air-cooling power generator, a cool air production device, a cool air passage, an air blower and a power generator air inlet temperature-humidity gauge, wherein the cool air production device is installed outside an air-cooling power generator air chamber, one end of the cool air passage is communicated with an air outlet of the cool air production device, the other end of the cool air passage is communicated with an air compensation port, the air blower is installed inside the cool air passage to be close to the air compensation port, the power generator air inlet temperature-humidity gauge is installed on an air inlet passage of the power generator to be close to a rotor, and an overhauling hole is provided with a hot air exhaustion door which can be opened and closed. Due to the adoption of the device, cool air produced by the cool air production device can be blown by the air blower into the air inlet passage of the power generator through the cool air passage via the air compensation port, so that the air inlet temperature can be reduced, the heat of a power generator stator coil can be adequately radiated, and the power generator can be operated at a full load at the high-temperature weather.

Owner:DYNAGREEN ENVIRONMENTAL PROTECTION GROUP

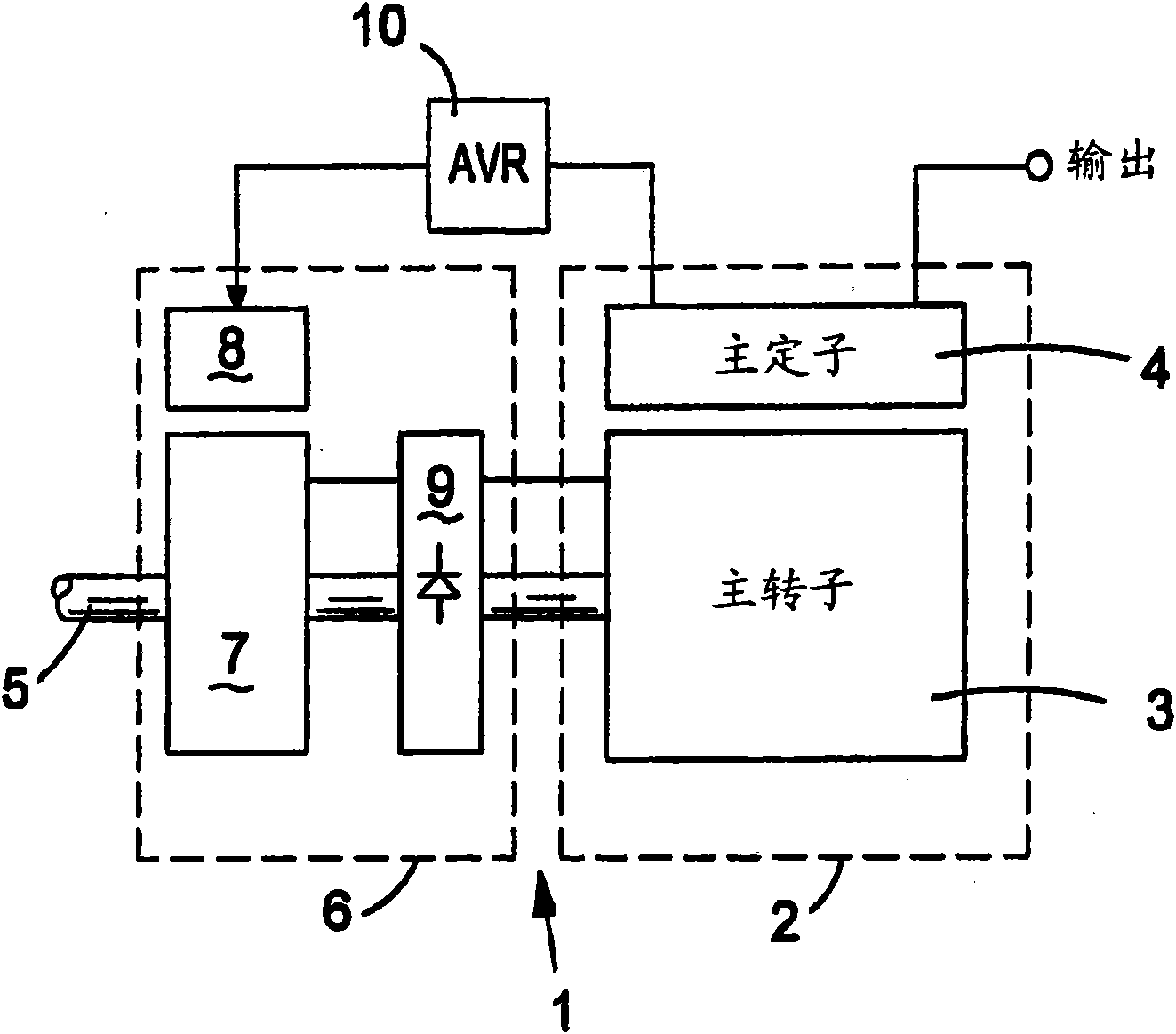

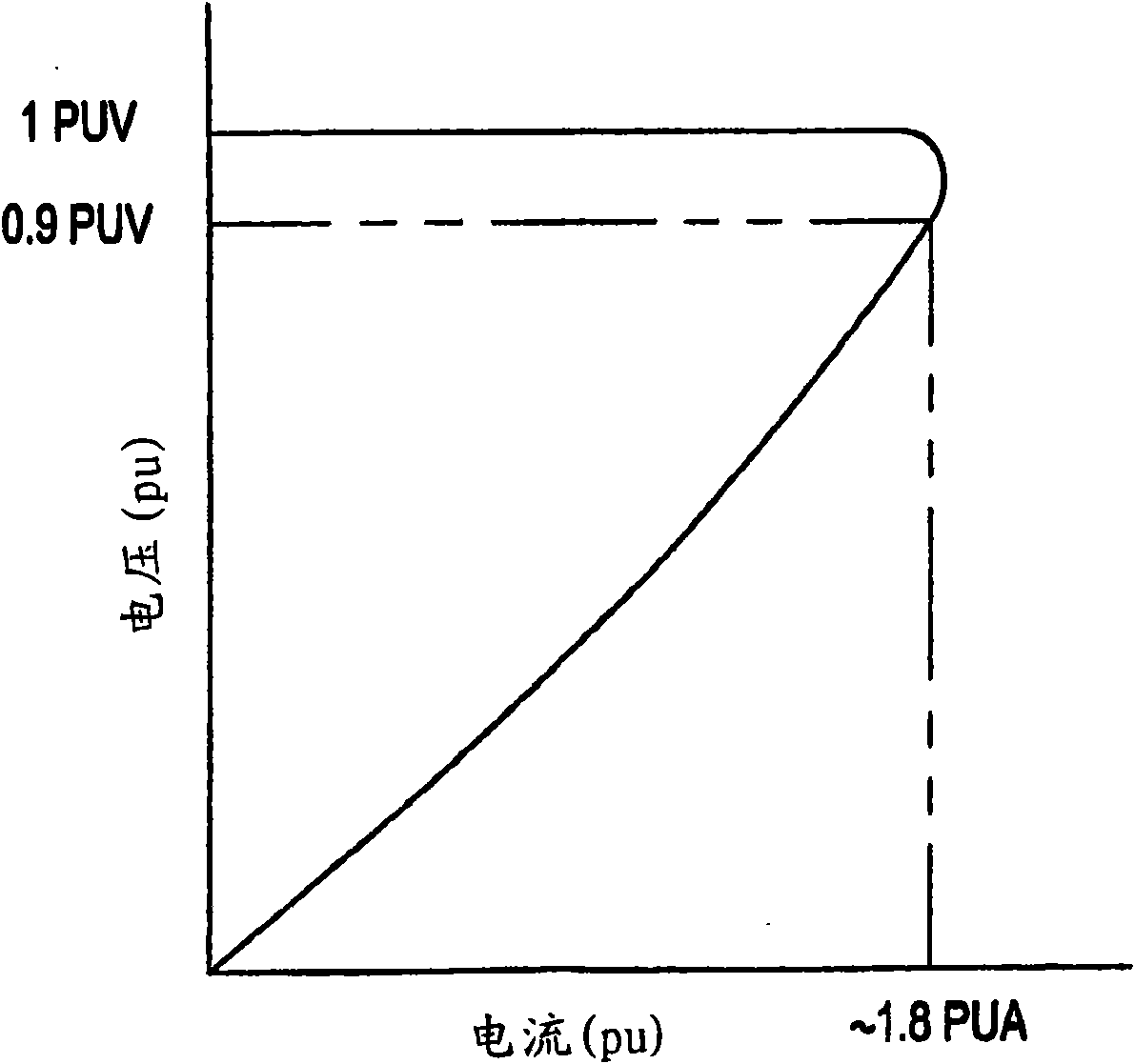

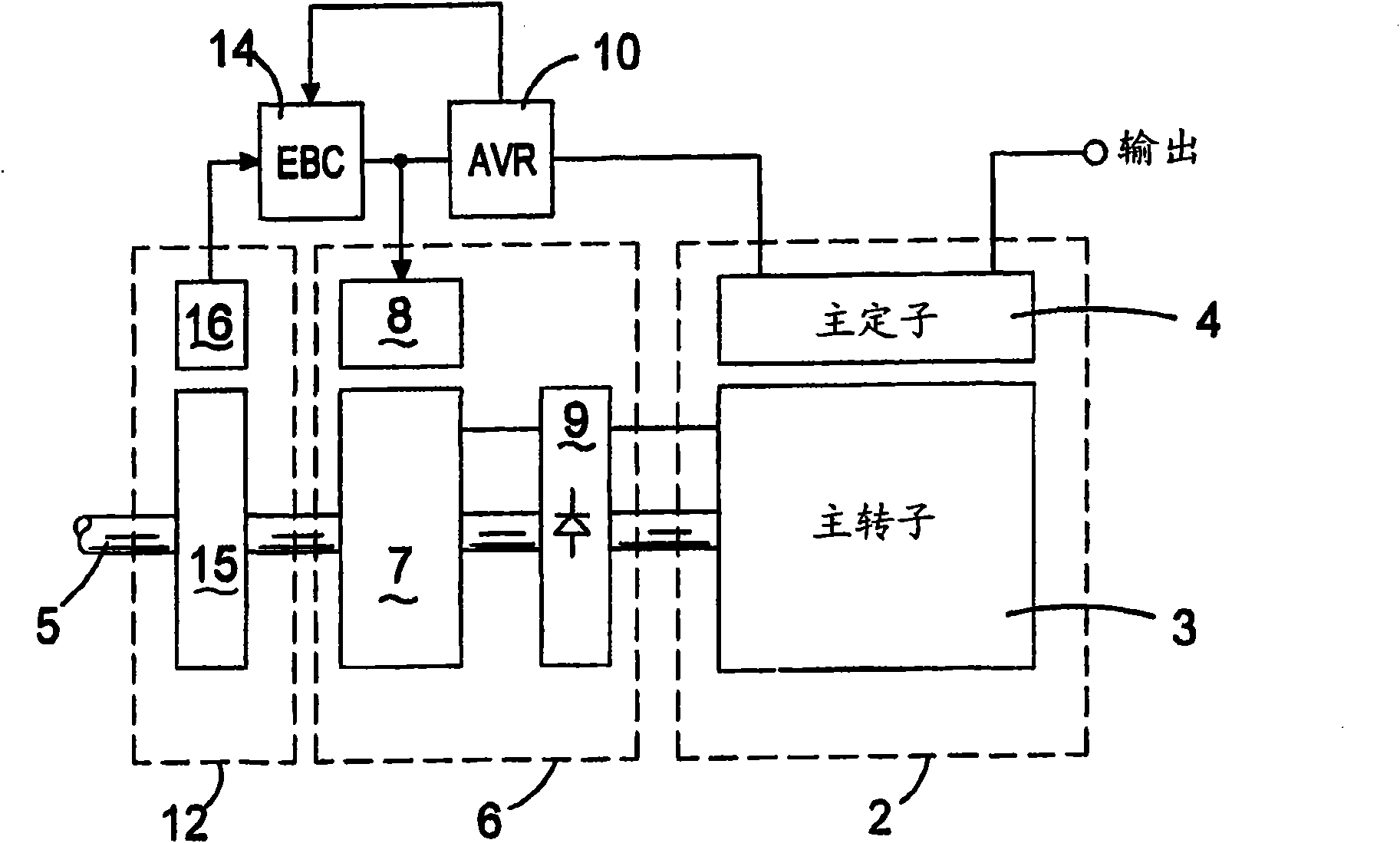

Method of and apparatus for controlling excitation

ActiveCN101632219AEasy to upgradeHigh overload performanceGenerator control by field variationControl powerEngineering

Excitation control circuitry for a synchronous generator is disclosed. The synchronous generator is of a type comprising a main machine (2) and an exciter (6) for exciting the main machine. The excitation control circuitry comprises an automatic voltage regulator (10) for controlling power flow from the main machine to the exciter, and an excitation boost system (14) for selectively supplying power from a second source of electrical power (12) to the exciter (6). This can allow additional excitation to be provided, for example, when the generator is in overload. This arrangement can allow a synchronous generator to be upgraded by adding the excitation boost system to provide enhanced overload performance.

Owner:CUMMINS GENERATOR TECH LTD

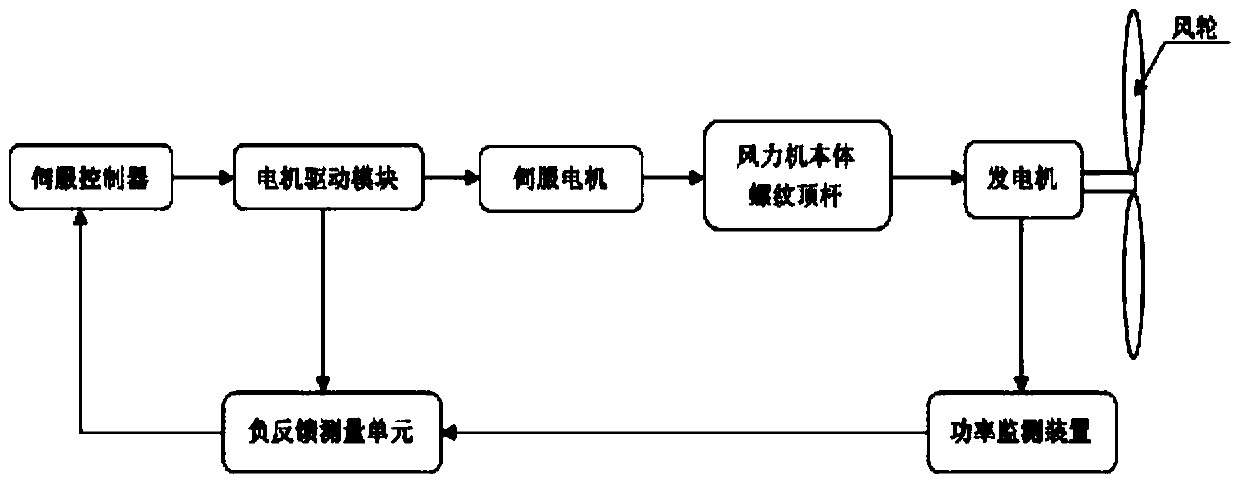

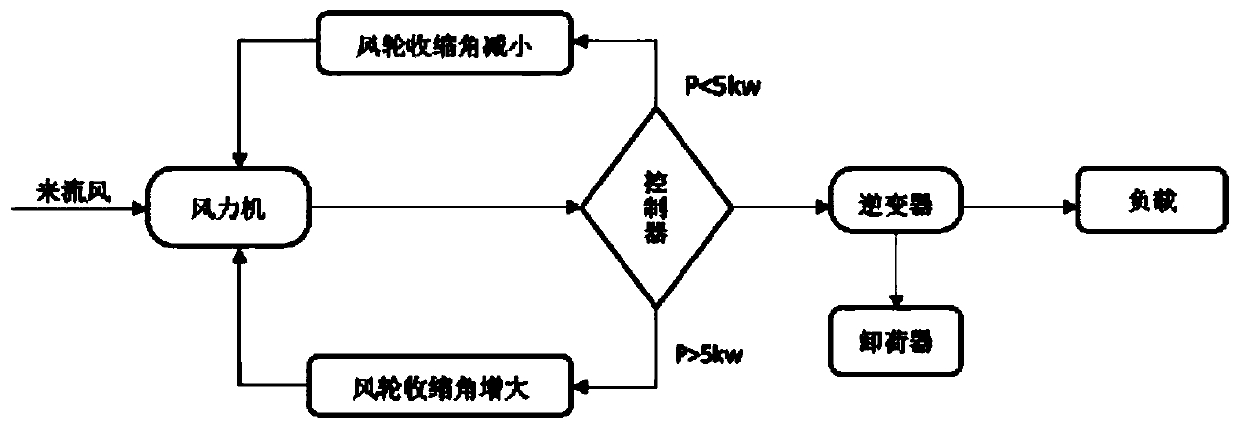

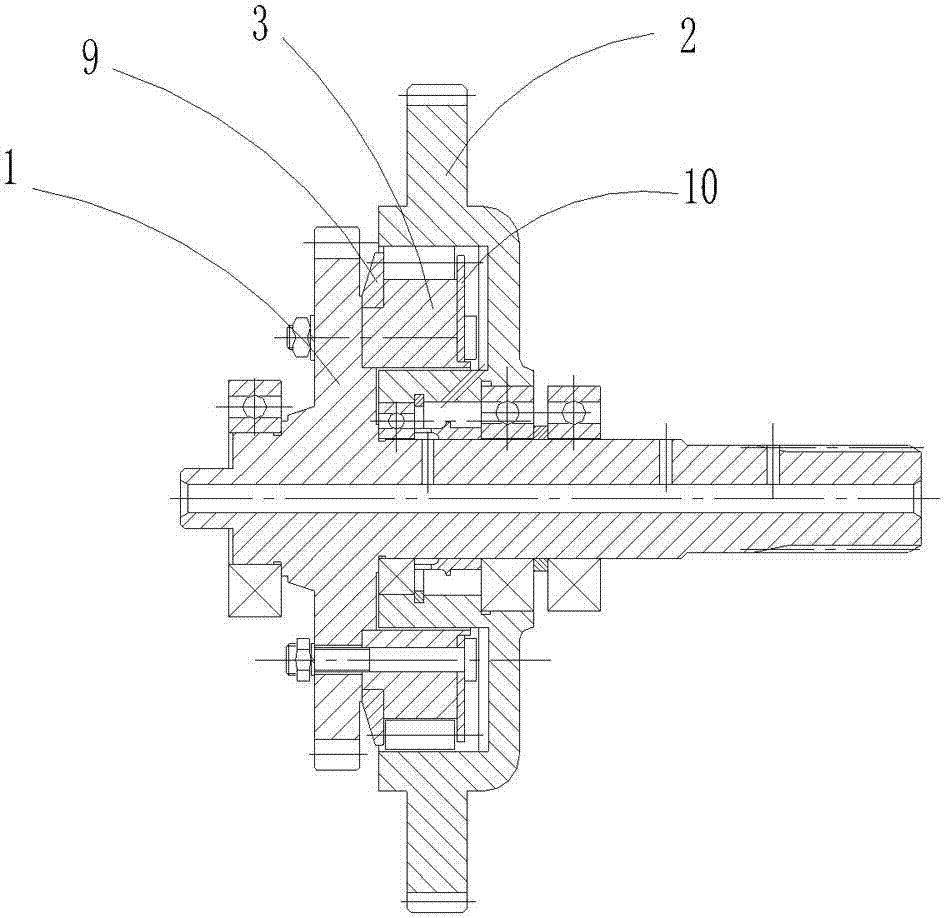

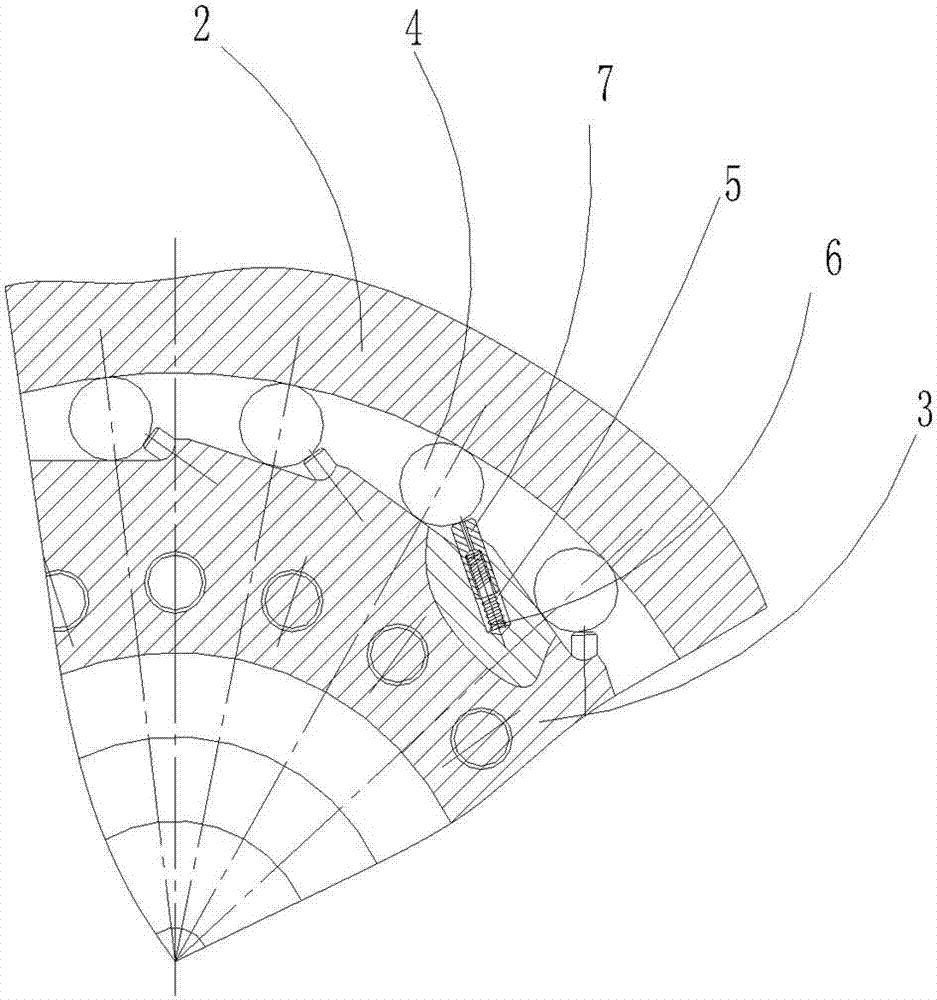

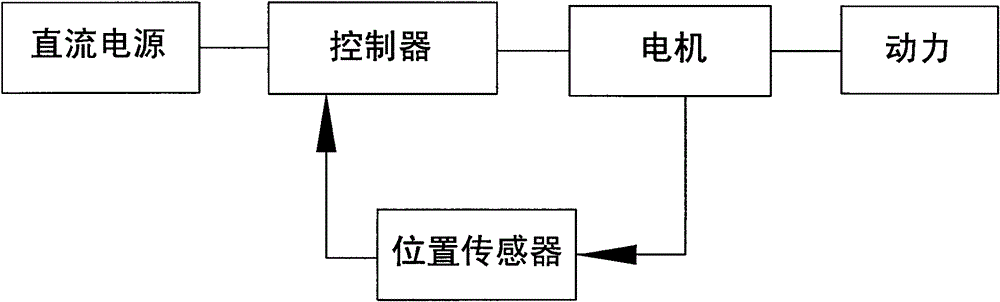

Electrical servo control system for umbrella-shaped wind turbine

PendingCN110173396AAccurateTimely feedbackWind motor controlMachines/enginesControl signalMechanical energy

The invention discloses an electrical servo control system for an umbrella-shaped wind turbine, and mainly relates to the technical field of wind power generation. The system involves a monitoring unit, a negative feedback measuring unit, a control unit, a driving unit, a power unit and an execution unit, wherein the monitoring unit is used for monitoring the power output of the umbrella-shaped wind turbine in the operation process to obtain an output value; the negative feedback measuring unit is used for receiving the output value and obtaining a first feedback signal through signal processing, and a driving signal of the driving unit is collected, and a second feedback signal is obtained through the signal processing; the control unit is used for receiving the first feedback signal andthe second feedback signal, and resolving the first feedback signal and the second feedback signal into a control signal; the driving unit is used for receiving the control signal and converting the control signal into a driving signal; the power unit is used for receiving the driving signal, and outputting mechanical energy corresponding to the driving signal; and the execution unit is used for utilizing the mechanical energy for changing the blade angle of the wind wheel. The control method based on the classic control algorithm has the advantages that the power monitoring requirement of thewind turbine generator with the umbrella-shaped adjusting mechanism is met, and the purpose of active power control is achieved.

Owner:INNER MONGOLIA UNIV OF TECH

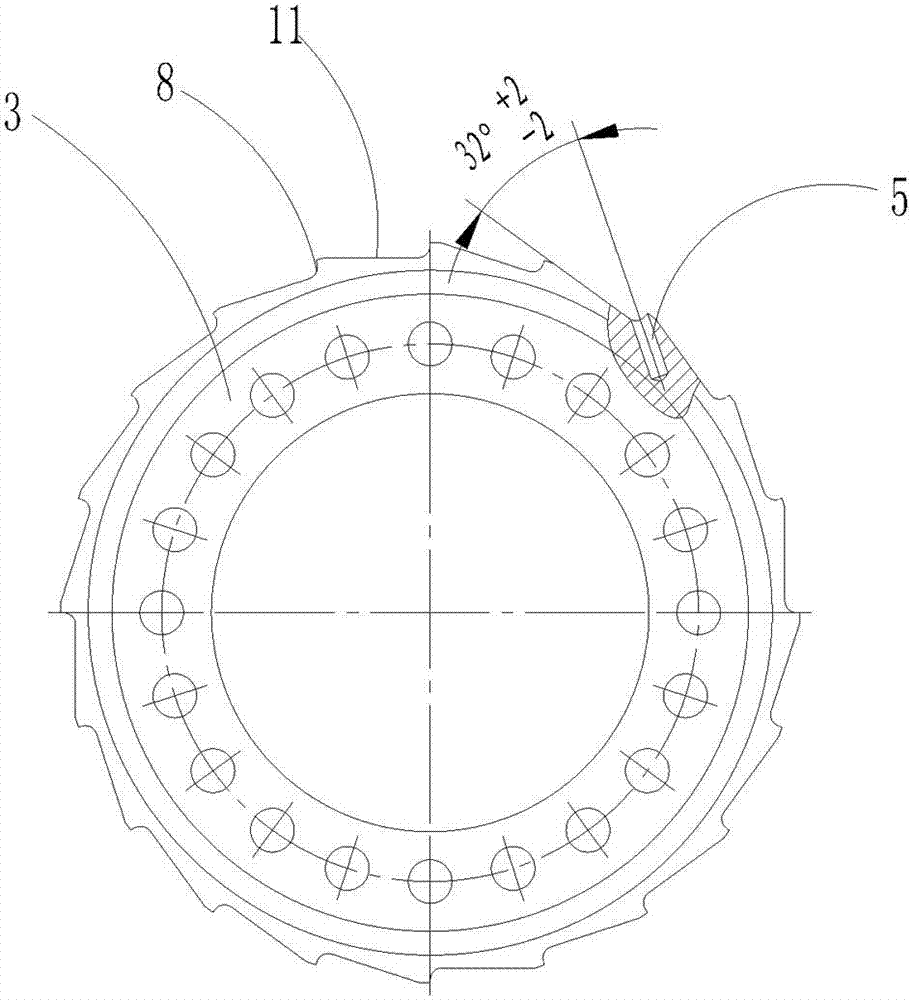

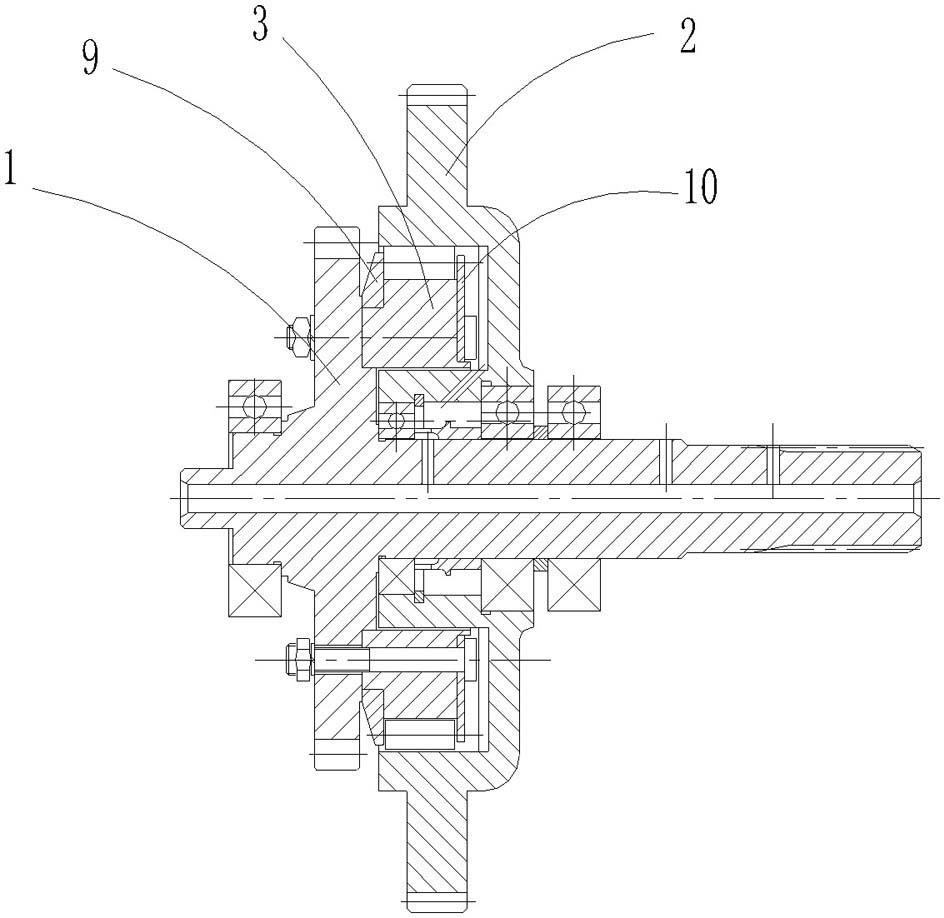

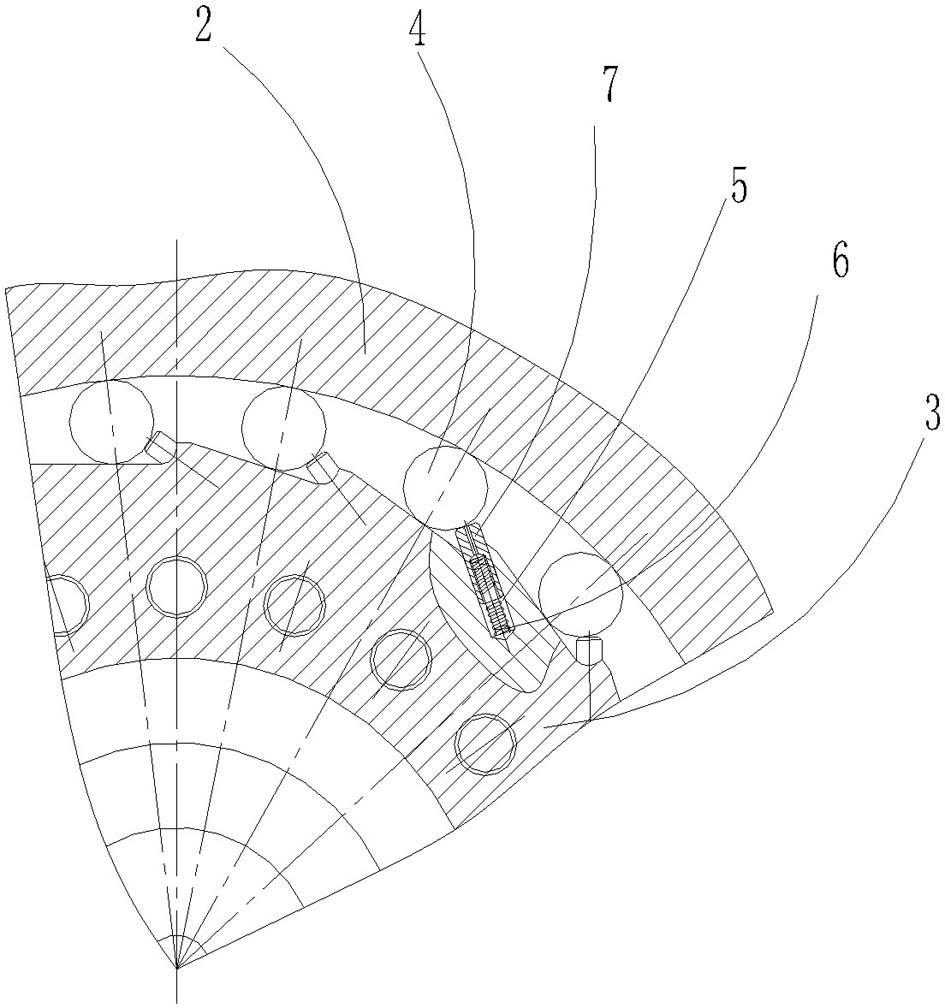

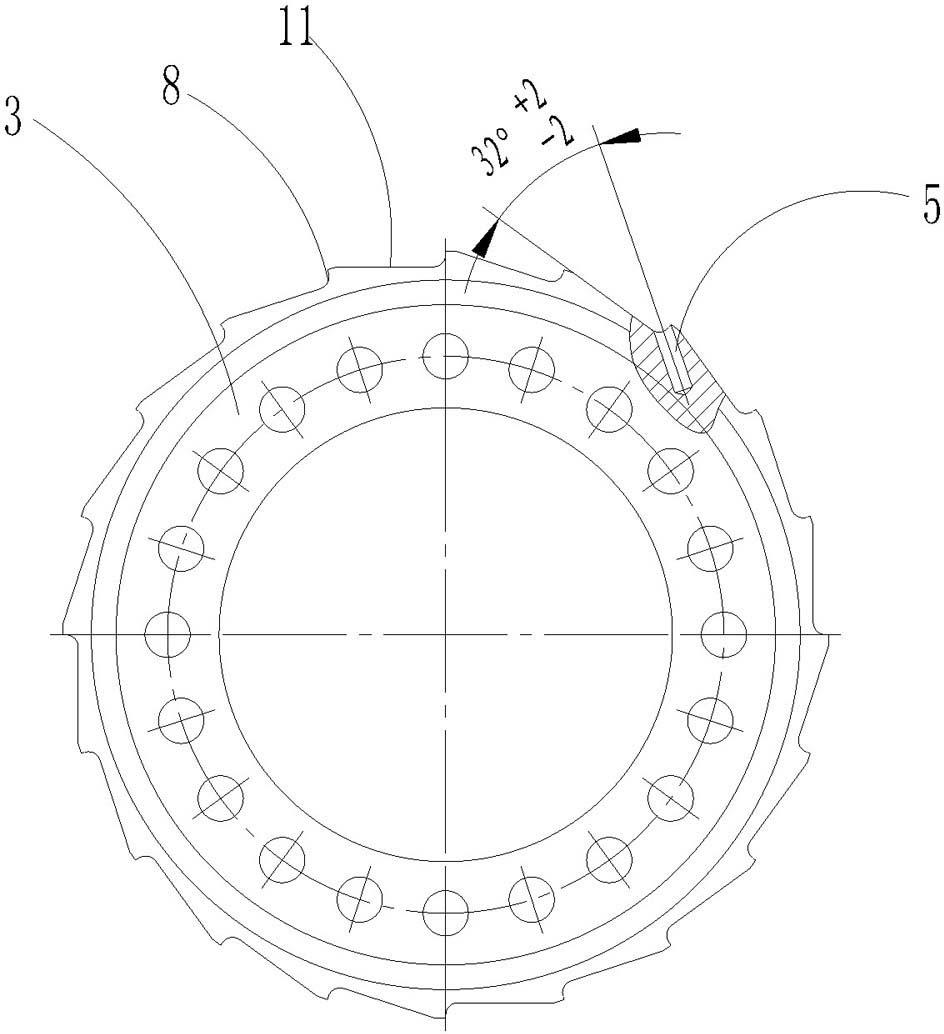

Spring resetting type overrunning clutch for energy-conservation type loader

The invention relates to the technical field of engineering machinery transmission, in particular to a spring resetting type overrunning clutch for an energy-conservation type loader with low rotating speed. An inclined angle between a spring resetting hole and an inner ring cam ranges from 30 degrees to 34 degrees; the diameter of the spring resetting hole ranges from 4.49mm to 4.538mm, and the depth of the spring resetting hole ranges from 15mm to 15.1mm; and the cross section of a roller path wall is circular arc-shaped. The spring resetting type overrunning clutch has a simple structure, a low reduction ratio, large transmission torque, good overloading performance and long service life, is stable in working and safe and reliable, and is beneficial to realizing energy conservation and emission reduction of the domestic loader and improving the performances of the whole loader.

Owner:HANGZHOU ZONGXING GEAR

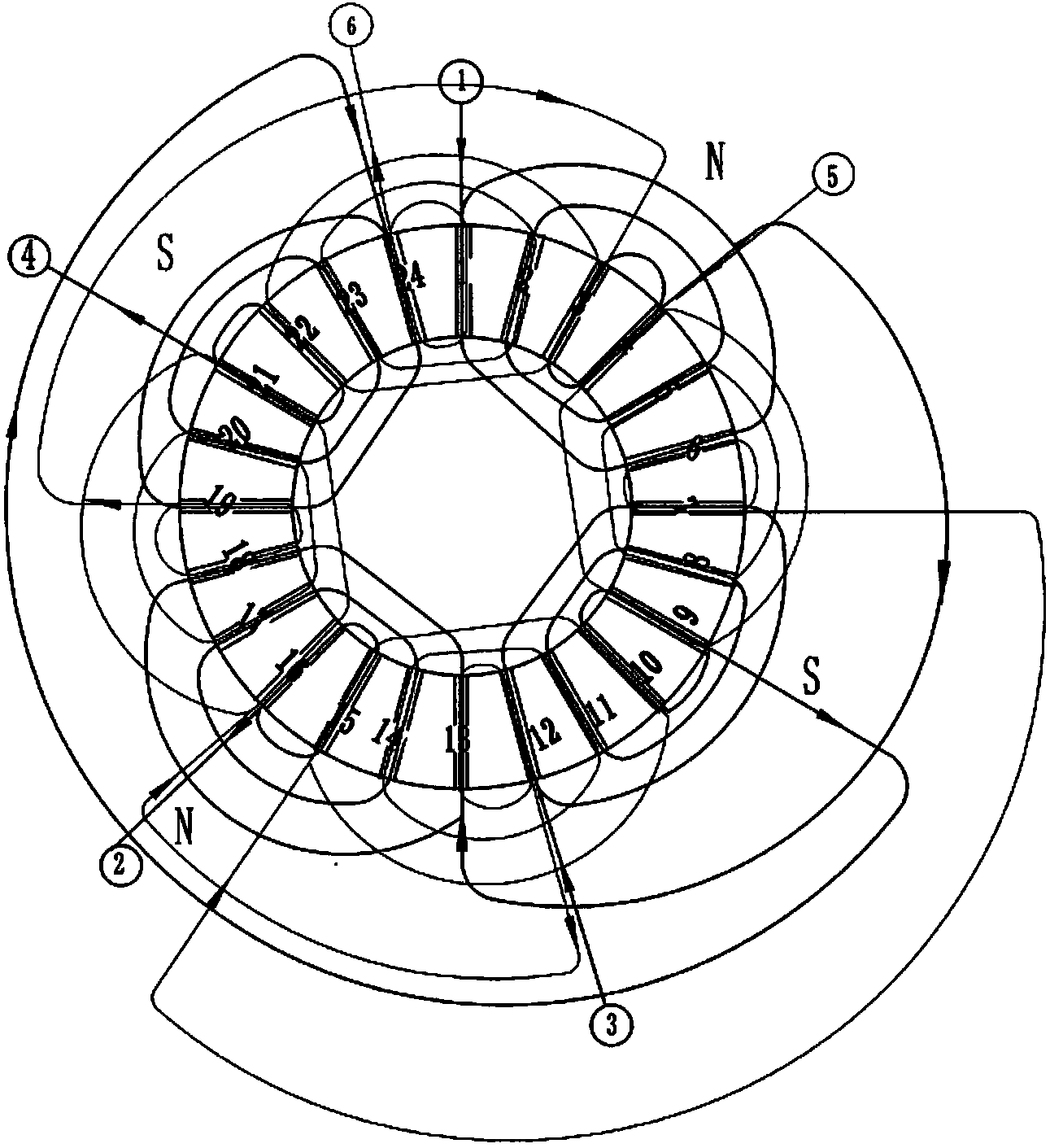

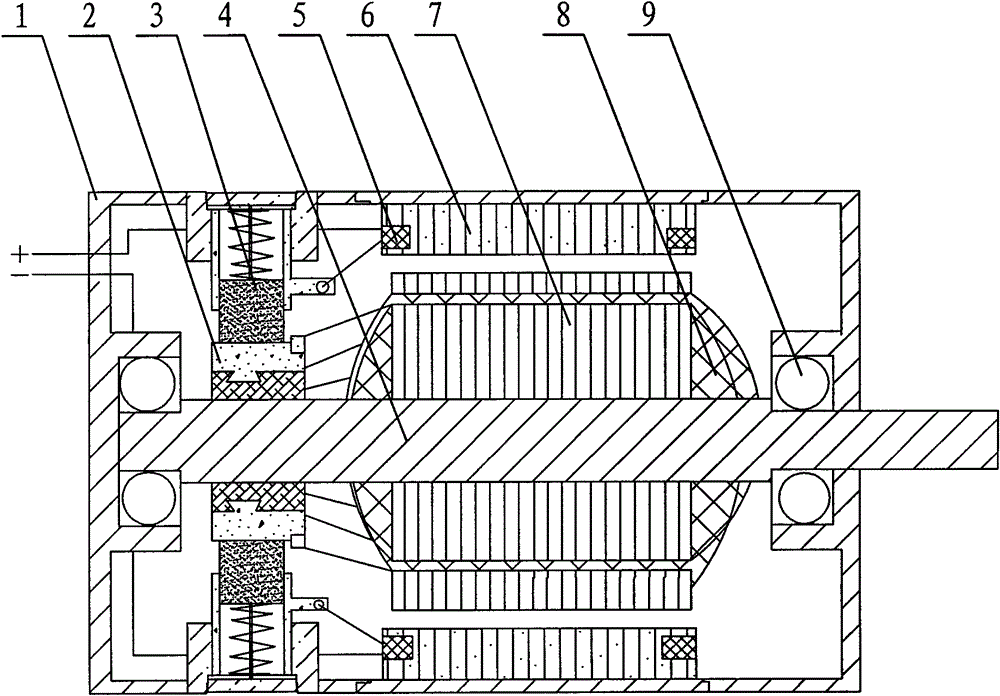

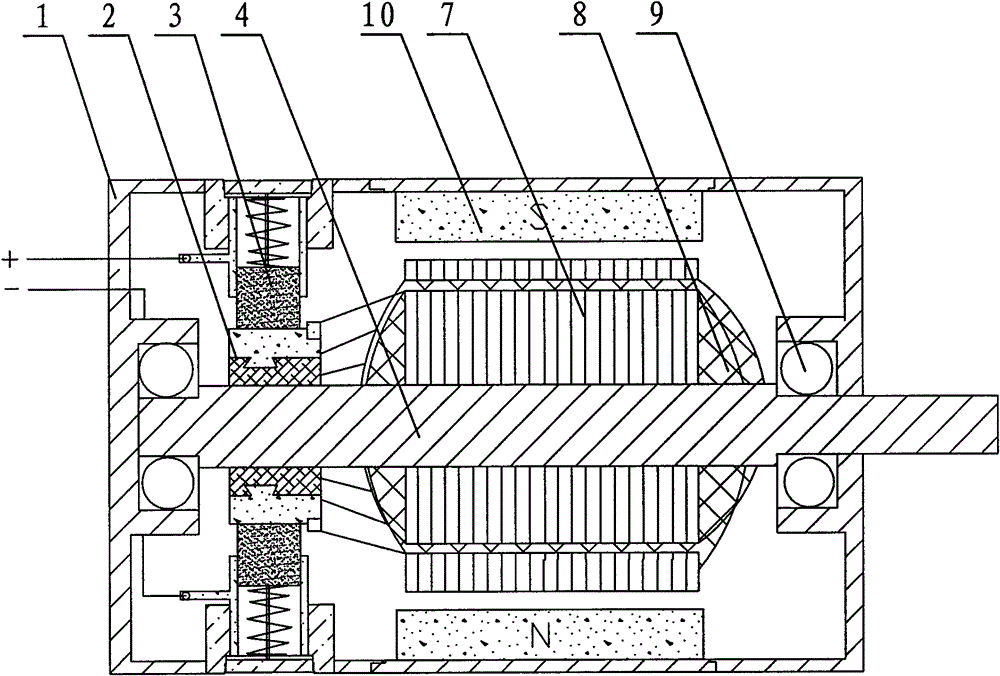

Electronic commutation electrically excited direct current motor

InactiveCN102801274AReduce speedStable output torqueAssociation with control/drive circuitsMagnetic circuit stationary partsConductor CoilPosition sensor

The invention discloses an electronic commutation electrically excited direct current motor, which comprises a motor body (1), a stator core (6), a rotor core (7), a rotating shaft (4), a position sensor (11), sensing magnetic steel (15) and a controller, wherein the rotating shaft (4) is arranged on the motor body (1); the rotor core (7) is fixed on the rotating shaft (4); at least a pair of stator armature windings (12) is arranged on the stator core (6); at least a pair of rotor excitation windings (16) is arranged on the rotor core (7); a collector ring (14) is fixed on the rotating shaft (4); an electric brush assembly (3) is fixed on the motor body (1); the rotor excitation windings (16) are connected with the collector ring (14); and when load current exceeds a set value, the controller regulates the excitation voltage of the rotor excitation windings (16) according to the load current of the stator armature windings (12). By the structure, the motor has the advantages of simple and rational structure, working stability, high efficiency, high overload capability, high efficiency and the like.

Owner:马加良

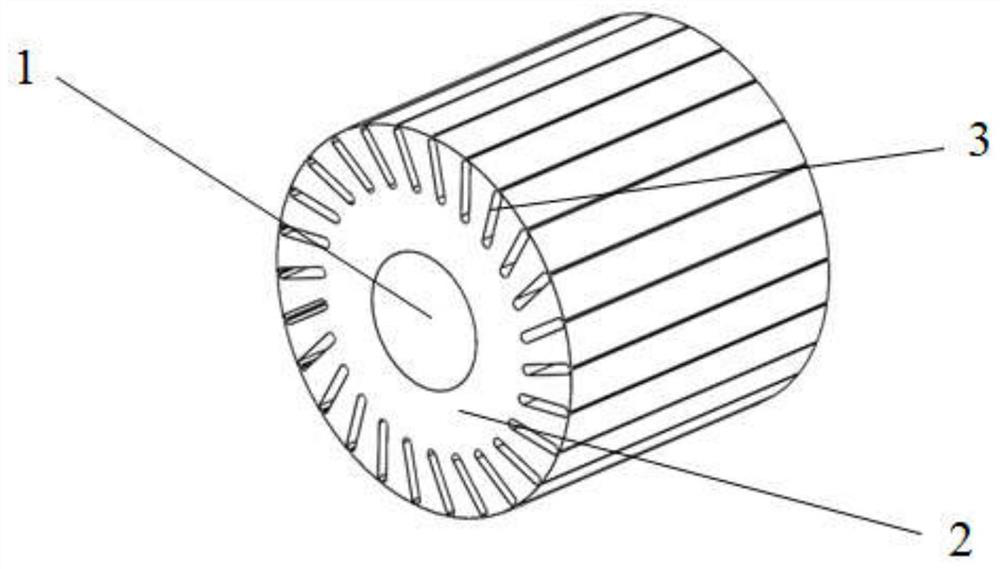

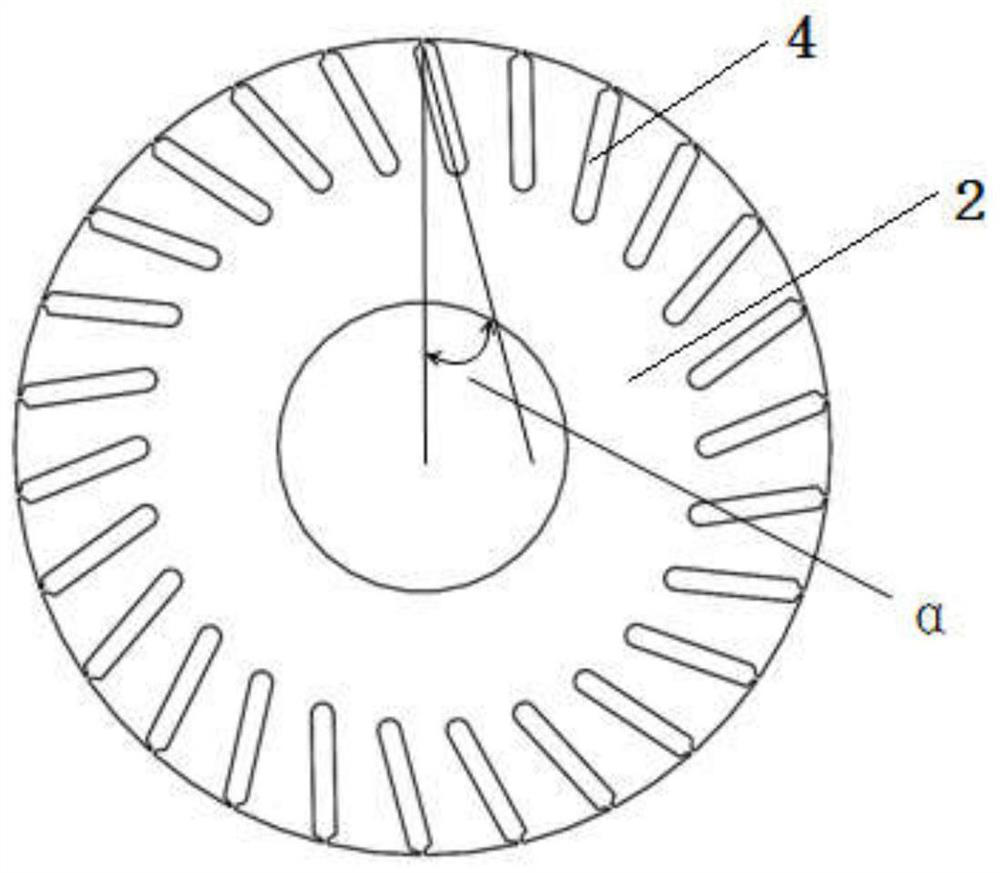

Radial skewed slot rotor and motor applying same

PendingCN112928841AImprove efficiencyIncrease powerMagnetic circuit rotating partsElectric machineClassical mechanics

The invention discloses a radialskewed slot rotor and a motor applying the same. The motor applying the radial skewed slot rotor comprises theradial skewed slot rotor. Theradial skewed slot rotorcomprises a rotating shaft, a plurality of rotor punching sheets and conducting bars, and the radial skewed slot rotor is mainly formed by coaxially laminating the plurality of rotor punching sheets, wherein a shaft hole is formed in the axis position of each rotor punching sheet, the position of a rotor notch is not changed, the center line of the rotor groove of the outer circle inclines by a certain angle along the radial direction of the rotor punching sheet to form an inclined rotating groove, and the plurality of rotating grooves are uniformly distributed along the circumference. The radial skewed slot rotor and the motor applying the radial skewed slot rotor can be directly applied to an existing asynchronous motor, and compared with an axial skewed slot rotor motor which is widely used at present, the equivalent slot depth and the equivalent guide bar length of the manufactured radial skewed slot rotor motor are reduced, so that the total leakage reactance value of the radial skewed slot rotor motor is reduced, the loss and the size of reactive current in the rotor are reduced, and the effects of improving the efficiency and the power factor and increasing the overload capacity are achieved.

Owner:HEFEI UNIV OF TECH

Variable frequency speed regulating disk type motor and vacuum pump

ActiveCN103457366BReduce volumeRealize the integration of machine and pumpMagnetic circuit stationary partsWindings conductor shape/form/constructionCapacitanceCompensation effect

The invention provides a variable frequency speed regulating disk type motor which uses sinusoidal windings and is in a double-layered type. Through interactive compensation action of two coils in each electrode of two main windings, the electrodes are sequentially connected, a magnetic filed is made to be distributed more evenly, the waveform is close to the sine wave, and declining of torque can not happen any more at a low rotating speed. Meanwhile, in the starting process, an auxiliary winding is connected with an operating capacitor and a starting capacitor, in the operating process, the auxiliary winding and the operating capacitor are connected, and startability and overload capacity are guaranteed. Meanwhile, through switching of the connecting mode of a high voltage and a low voltage, when the motor works in the high voltage of 200V-240V, the first main winding and the second main winding are in parallel connection with an auxiliary winding circuit after being in series connection, and when the motor works in the low voltage of 100V-120V, the first main winding, the second main winding and the auxiliary winding circuit are in mutual parallel connection. The variable frequency speed regulating disk type motor meets the operating demands in different rotating speed range under a general voltage condition in the global range. In addition, integration of the motor and a pump is achieved when the variable frequency speed regulating disk type motor is applied to a vacuum pump.

Owner:北京富特盘式电机有限公司

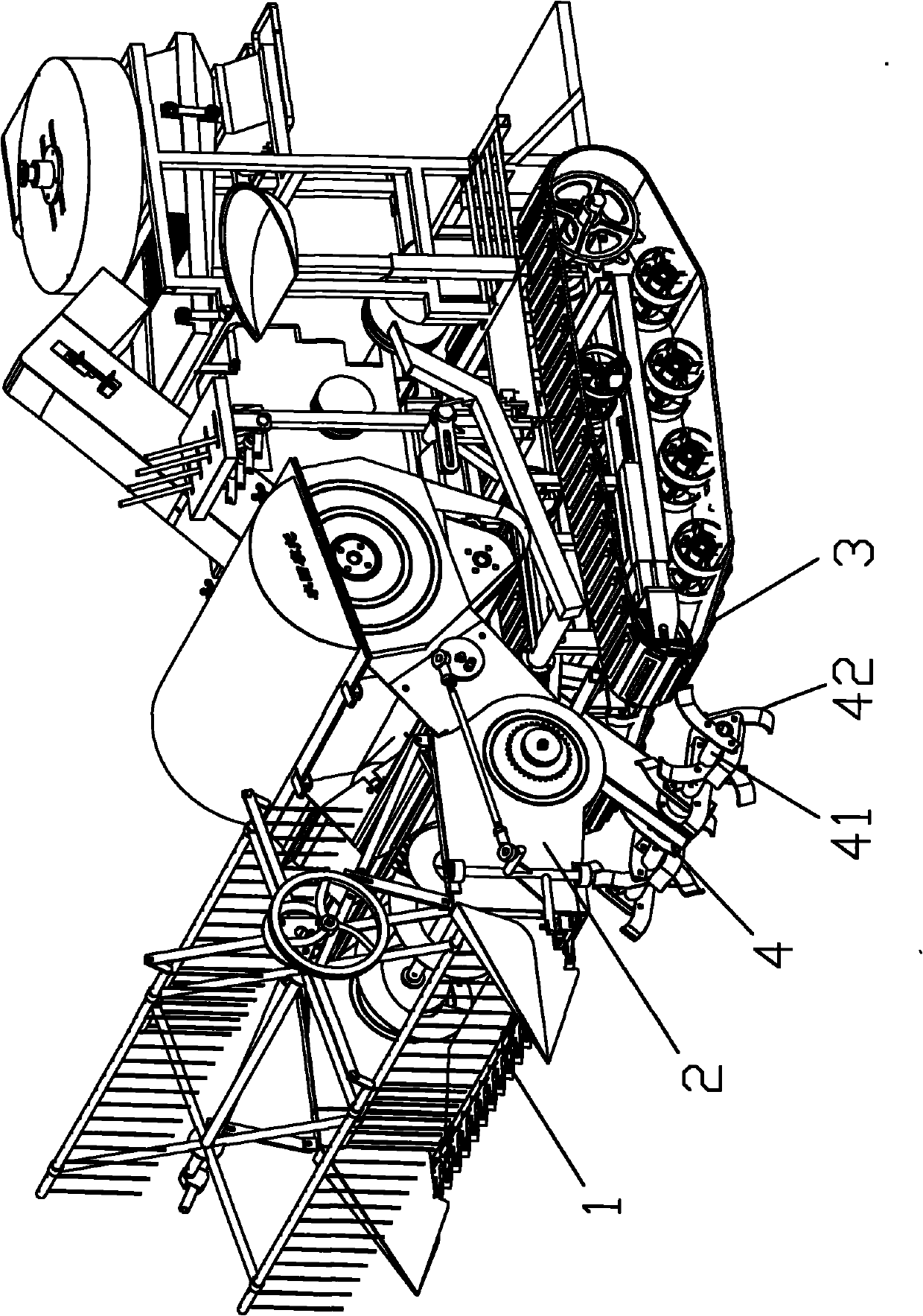

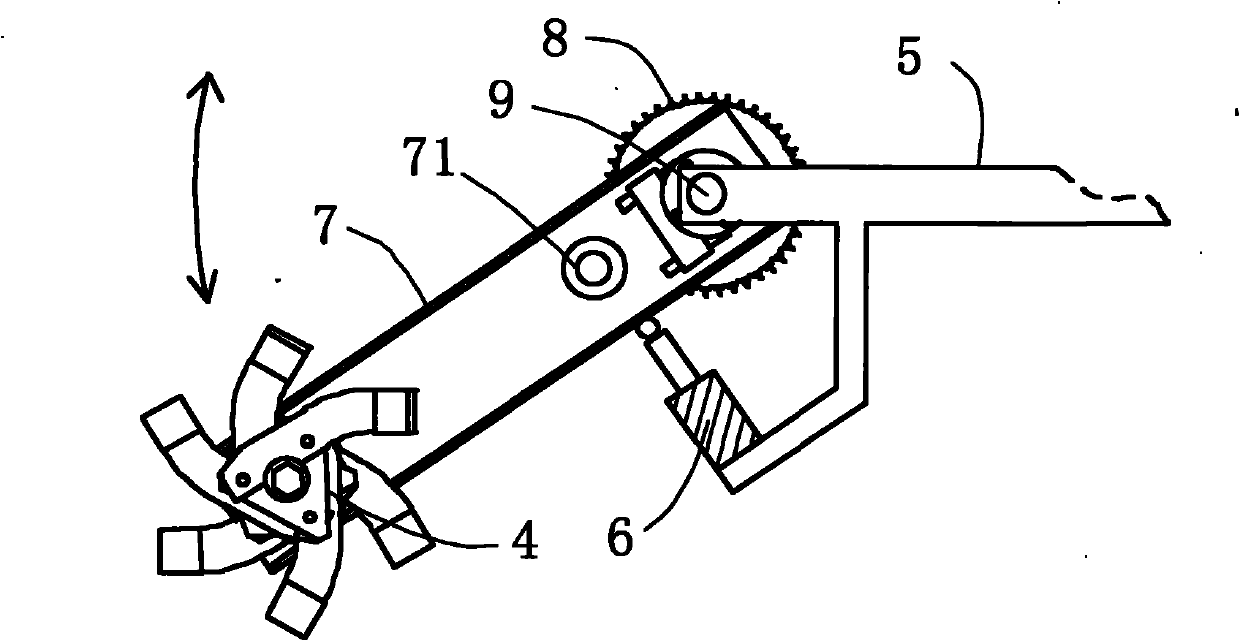

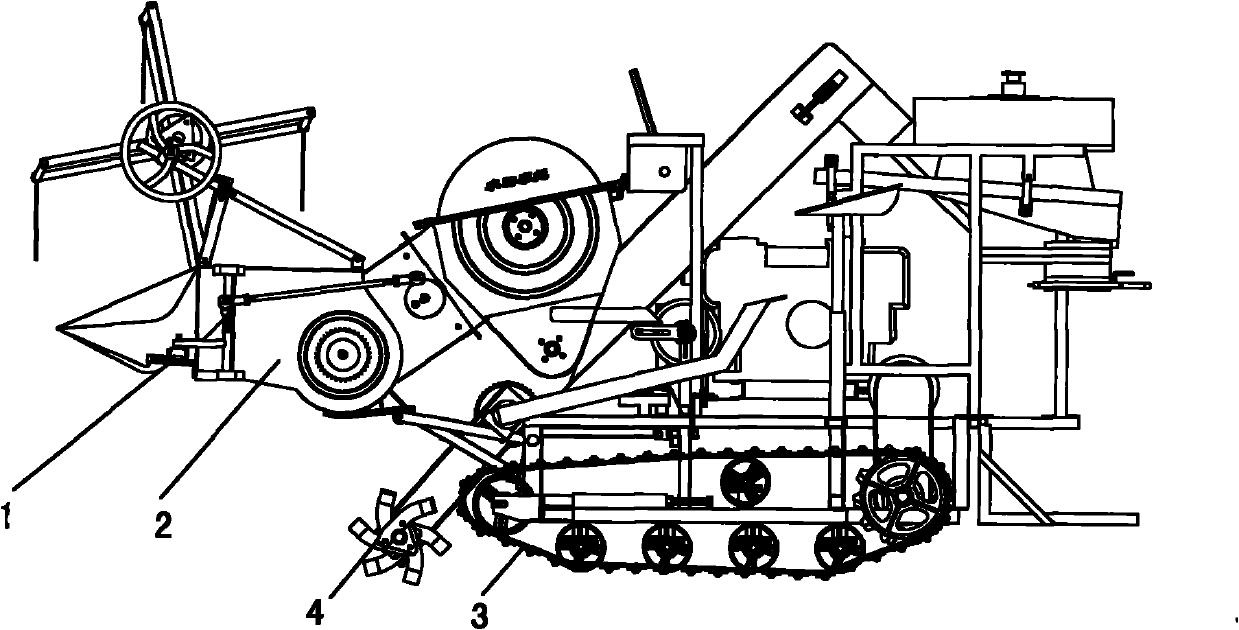

Combine harvester with rotary stubble cutter

The invention discloses a combine harvester with a rotary stubble cutter, comprising an upper cutter device, a walking mechanism and a cutting table, wherein a rotary stubble cutter is arranged in front of the walking mechanism and at the rear lower side of the upper cutter; the rotary stubble cutter comprises a rotating shaft driven by power; and a plurality of sets of rotating pieces are fixedly arranged on the rotating shaft. The invention can lower the heights of remained stubbles and has small working load, strong overload capacity and difficult damage.

Owner:李源湘

Spring resetting type overrunning clutch for energy-conservation type loader

ActiveCN102182769ARealize fuel saving and emission reductionHigh torque transmissionFreewheel clutchesReduction ratioCam

The invention relates to the technical field of engineering machinery transmission, in particular to a spring resetting type overrunning clutch for an energy-conservation type loader with low rotating speed. An inclined angle between a spring resetting hole and an inner ring cam ranges from 30 degrees to 34 degrees; the diameter of the spring resetting hole ranges from 4.49mm to 4.538mm, and the depth of the spring resetting hole ranges from 15mm to 15.1mm; and the cross section of a roller path wall is circular arc-shaped. The spring resetting type overrunning clutch has a simple structure, a low reduction ratio, large transmission torque, good overloading performance and long service life, is stable in working and safe and reliable, and is beneficial to realizing energy conservation and emission reduction of the domestic loader and improving the performances of the whole loader.

Owner:HANGZHOU ZONGXING GEAR

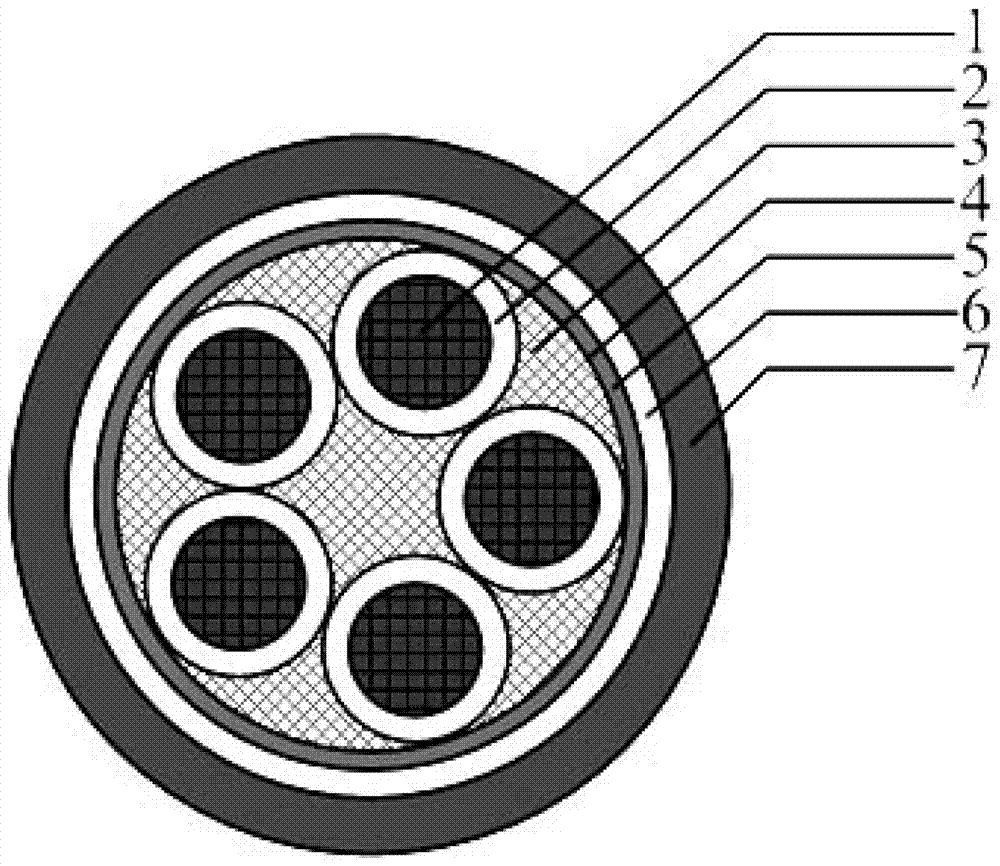

Energy-saving and environmental-protection crosslinking power cable

InactiveCN107464624AImprove overload capacityHigh overload performanceInsulated cablesPower cablesSelf lockingSmoke

A cross-linked energy-saving and environment-friendly power cable, which includes a cable core formed by twisting and winding a plurality of insulated wire cores, and the cable core is wrapped with an inner lining layer, an armor layer and an outer sheath layer in sequence from the inside to the outside. , in the insulated core, the single-filament stranded circular copper conductor of the type wire is wrapped with a high-temperature radiation-resistant cross-linked flame-retardant polyolefin insulating layer; Combustion belt; the inner lining layer is two layers of polyester tape wrapped around the outside of the tape layer; the armor layer is an aluminum alloy tape interlocking armor structure; the outer sheath layer is halogen-free and low-smoke High temperature radiation cross-linked flame retardant polyolefin sheath layer. The cross-linked energy-saving and environment-friendly power cable provided by the present invention can solve the problems of relatively high consumption of existing cable materials, easy damage due to overheating and excessive bending, and secondary harmful pollutants during combustion. It has the advantages of material saving, strong overload capacity, and halogen-free Low-smoke, flame-retardant, fire-resistant, self-locking protection characteristics, the cable operation is safer and more reliable, and the service life is longer.

Owner:湖北龙腾红旗电缆(集团)有限公司

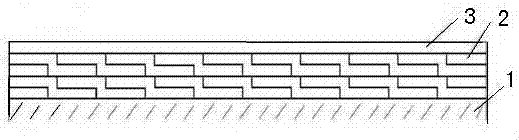

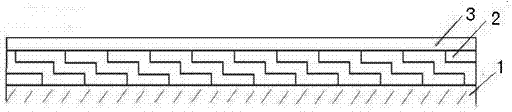

Method for manufacturing winding wires

InactiveCN102231306AFlat surfaceHigh mechanical strengthInsulating conductors/cablesGlass fiberVacuum pressure

The invention provides a method for manufacturing winding wires. The method comprises the following steps: (1) covering a first layer of mica tapes horizontally; (2) covering a second layer of mica tapes horizontally; (3) covering a third layer of mica tapes horizontally; (4) carrying out winding covering; and (5) sintering, cooling and rolling. The winding wires manufactured by the method are smooth in surface, high in mechanical strength, good in manufacturability, strong in overload capacity and good in wet-heat resisting property; compared with glass fibers, the abrasive resistance of the winding wires is improved remarkably; the tiny gaps are generated when lap taping does not exist and the winding wire are easy to penetrate when vacuum pressure is utilized to soak, thus motor insulation realizes non-gap insulation; and the winding wires are applied to manufacturing stator coils of 6kV and 10kV motors.

Owner:JIANGSU ICE CITY INSULATION MATERIALS STOCK

Anti-lock hydraulic braking system, in particular for motorized two-wheel vehicles

InactiveUS8205949B2Simpler and less-expensiveDisruptive effectBraking action transmissionBraking systemBrake pressure

An anti-lock hydraulic braking system has a wheel brake circuit with a main brake cylinder, wheel brake cylinder and switching valve, and an auxiliary pressure circuit, connected in parallel between the switching valve and wheel brake cylinder on the wheel brake circuit. With ABS control, the switching valve can be switched from a basic position, where it hydraulically connects the main brake cylinder and wheel brake cylinder, to a switched position where it prevents a build-up of braking pressure on the wheel brake cylinder via the main brake cylinder, while the braking pressure on the wheel brake cylinder can be modulated by the auxiliary pressure circuit.

Owner:FTE AUTOMOTIVE GMBH & CO KG

Preparation method of heating type thermocouple liquid level measurement sensor

ActiveCN103162768BImprove accuracyImprove reliabilityLevel indicators by physical variable measurementLiquid level measurementPhysical chemistry

The invention relates to a preparation method of a heating type thermocouple liquid level measurement sensor. According to the preparation method of the heating type thermocouple liquid level measurement sensor, prepared heating elements and prepared armored cables are assembled together and fully sealed so that the heating type thermocouple liquid level measurement sensor can be obtained. The heating type thermocouple liquid level measurement sensor prepared through the method has the advantages of being capable of accurately judging a liquid-gas (vapor) interface under the conditions of high temperature and high pressure, good in reproducibility and high in resolution, capable of meeting requirements of an overload test, capable of accurately judging the liquid-gas (vapor) interface under severe environments of high temperature and high pressure, simple in process and good in uniformity of products.

Owner:CHONGQING MATERIALS RES INST

Slotless permanent magnet motor

InactiveCN1756031AAvoid Hysteresis LossAvoid eddy current lossMagnetic circuit stationary partsWindings conductor shape/form/constructionHysteresisPunching

The invention relates to a slotless permanent-magnet machine comprising stator components. The invention is characterized in that: said stator components comprise a false stator (5); an iron core (6) and a stator winding (7). Wherein, said false stator (5) is sheathed outside the iron core (6); said stator winding (7) is arranged of wire outside the false stator (5); and said false stator (5) is made from insulation material. The invention replaces the groove and tooth on the punching sheet of stator iron core with insulated false stator (5) to effectively solve the problem of slot electric machine as slot effect, hysteresis loss, eddy current loss and eddy current loss. The invention has higher load efficiency, continuous speed regulation, better acceleration property, higher overload capacity, smaller volume, stable operation, small torque fluctuation and simple manufacture process.

Owner:BYD CO LTD

A circulating permanent magnet linear motor

ActiveCN104967277BLow costSimple structurePropulsion systemsPermanent magnet linear motorEngineering

Owner:中安星瑞航空科技有限公司

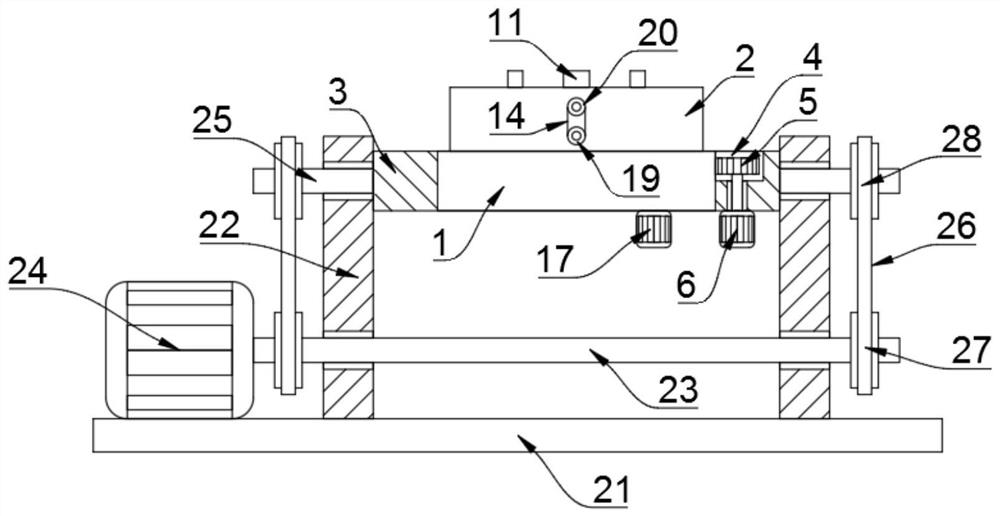

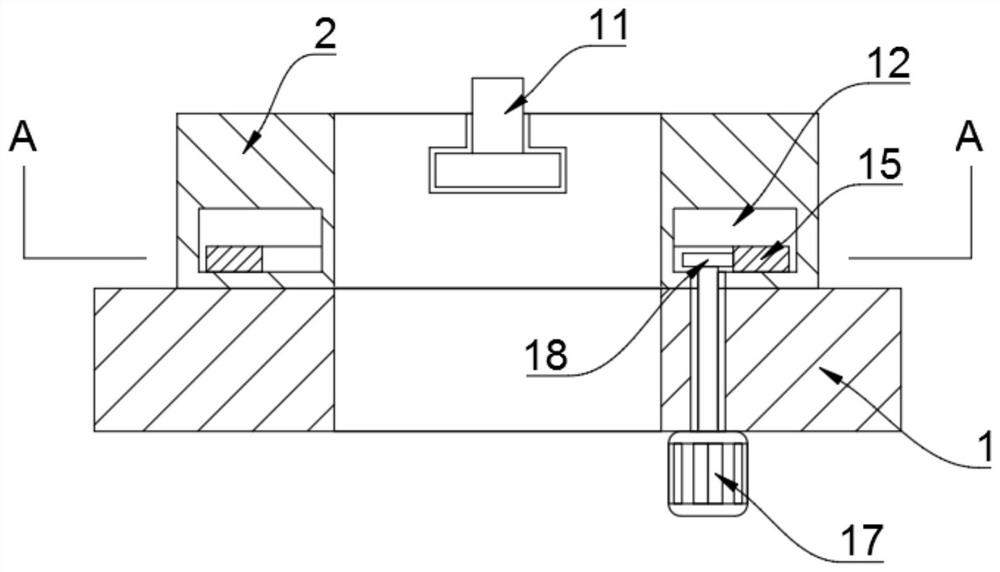

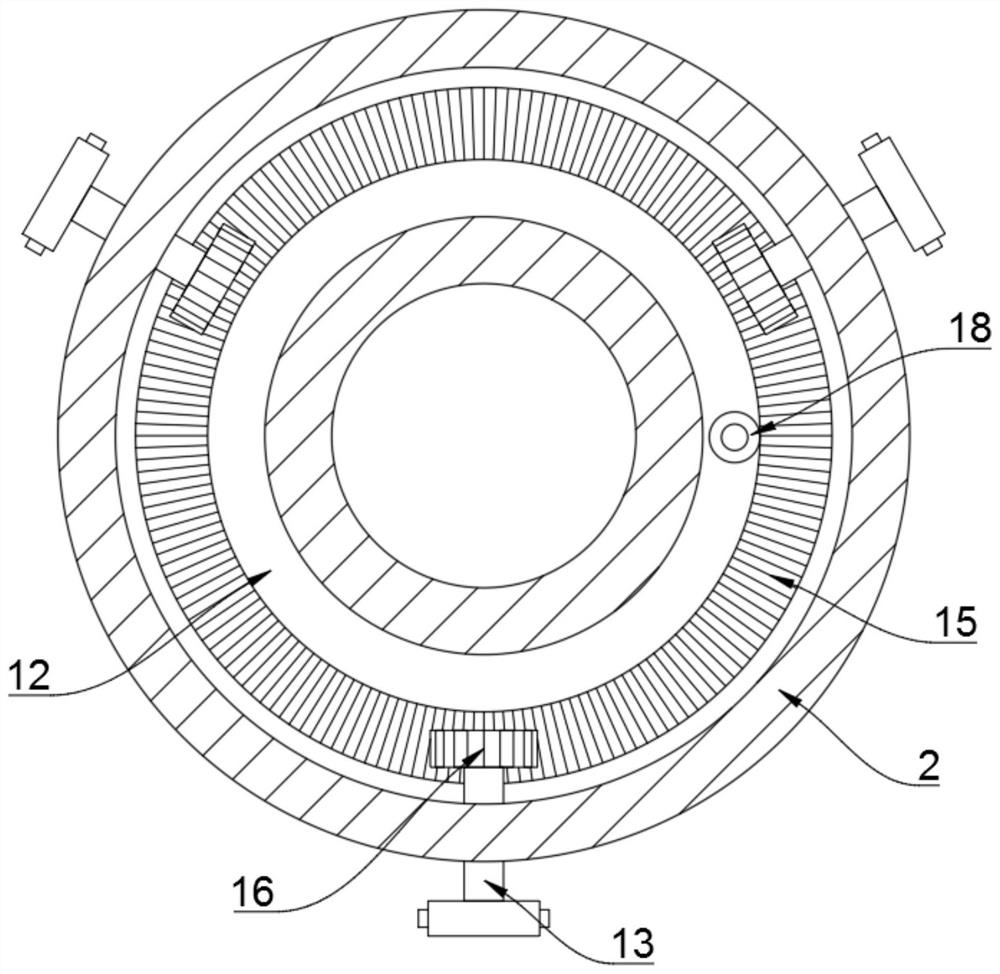

High-precision stepping motor driving chuck device for automatic welding

ActiveCN113618327AWide range of applicationsReduce precision errorWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDrive shaft

The invention discloses a high-precision stepping motor driving chuck device for automatic welding. The high-precision stepping motor driving chuck device comprises a fixing mechanism, the fixing mechanism comprises a rotating ring, the upper end of the rotating ring is fixedly connected with a chuck, the rotating ring is rotationally sleeved with an adjusting ring, a step is arranged on the inner side wall of the upper end of the adjusting ring, and a first gear is arranged in the step; an annular tooth groove matched with the first gear is formed in the side wall of the rotating ring, a first motor is fixedly connected to the lower end of the adjusting ring, a driving shaft of the first motor rotationally penetrates through the adjusting ring and is coaxially and fixedly connected with the first gear, three T-shaped open grooves are formed in the inner side wall of the upper end face of the chuck, and the three T-shaped open grooves are provided with clamping mechanisms. By means of the high-precision stepping motor driving chuck device, welding pipes of different sizes can be machined, machining of vertical pipes and horizontal pipes can be achieved, the application range is wide, and the welding and cutting quality can be guaranteed.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

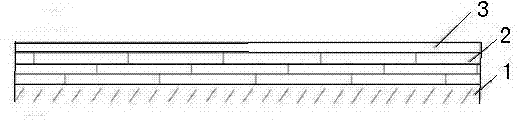

Double-glass-fiber and thin film wrapped electrical flat type aluminum wire

The invention provides a double-glass-fiber and thin film wrapped electrical flat type aluminum wire. The double-glass-fiber and thin film wrapped electrical flat type aluminum wire comprises a flat type aluminum wire body, a thin film layer wrapping the flat type aluminum wire body and a double-glass-fiber wrapping layer wrapping the thin film layer, and glass fibers are alkali-free glass fibers. According to the double-glass-fiber and thin film wrapped electrical flat type aluminum wire, the thin film and the glass fibers are bonded to form an integral insulation layer. The insulation layer has certain abrasion resistance, adhesiveness, flexibility and voltage resistance performance, and the flat type aluminum wire is made to have good heat flush and overload resistance performance. The double-glass-fiber and thin film wrapped electrical flat type aluminum wire is generally suitable for winding wires of electrical products with high voltages, low voltages, middle capacity and large capacity.

Owner:海安县天星电工材料有限公司

Permanent Magnet Synchronous Traction Motors for EMUs

ActiveCN104767337BImprove efficiencyIncrease powerSynchronous machine detailsMagnetic circuit rotating partsSynchronous motorPunching

The invention relates to a motor, in particular to a permanent-magnet synchronous traction motor for a motor train. The permanent-magnet synchronous traction motor for the motor train solves the problem that an existing permanent-magnet synchronous motor is not suitable for being directly used as a permanent-magnet synchronous traction motor for a motor train due to structure defects. The motor adopts a novel rotor magnetic circuit structure punching plate, a high-integration compact type rotor structure, a detachable connecting box structure and a lead structure. A connecting box can be conveniently disassembled so that the motor can be installed easily. A U-shaped magnetic circuit permanent magnet structure of an inner rotor is adopted, the magnetic separation bridge and circular bead design is added, and therefore the start and overload capacity of the motor can be improved. A rotor pressing ring at the driving end integrates rotor core pressing, permanent magnet end face pressing, rotor dynamic balancing and an inner seal ring labyrinth seal structure into a whole, the advantages that the structure is compact, the axial occupied space is small, and the installation is convenient are achieved, and the motor can be widely applied in the field of locomotive trains. According to the research, development and the operation of the permanent-magnet synchronous traction motor for the motor train, realistic bases are supplied for the permanent-magnet motor to research and develop a permanent-magnet traction motor structure with higher power, higher rotation speed and higher power density.

Owner:CRRC YONGJI ELECTRIC CO LTD

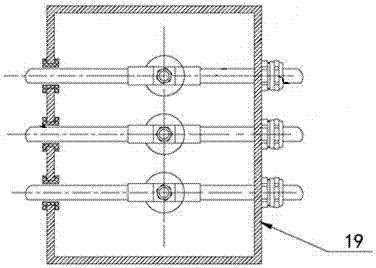

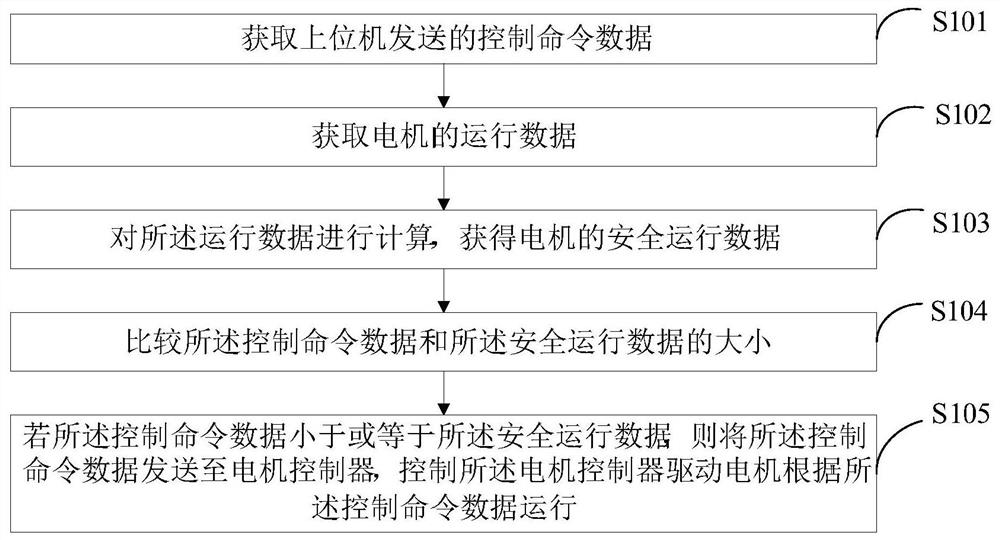

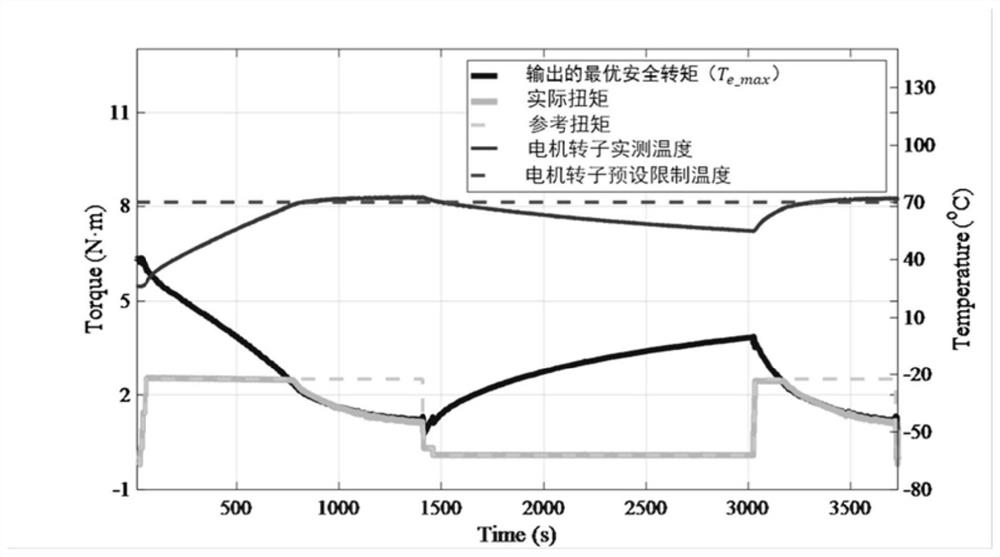

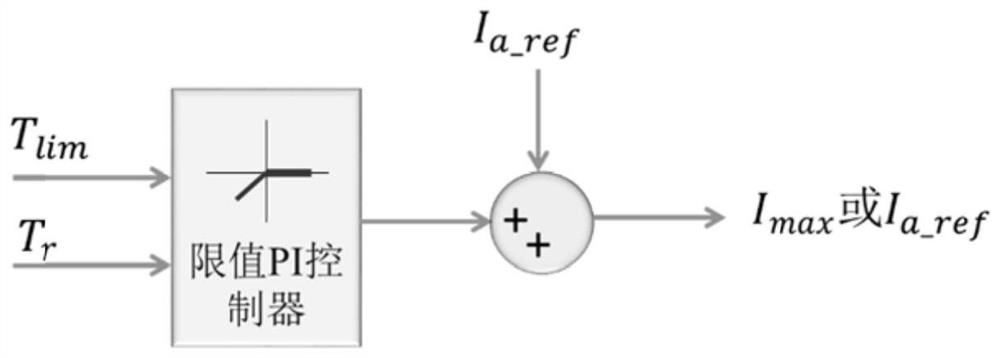

A motor function safety control method and device

ActiveCN110995117BHigh overload performanceIncreased torque densityElectric motor controlControl engineeringSafety control

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Non-aging aluminum alloy wire and its manufacturing method

ActiveCN103545010BImprove conductivityReduce resistance lossPower cablesMetal/alloy conductorsHysteresisUltimate tensile strength

The invention relates to a method for manufacturing a non-aging aluminum alloy wire, in particular to a method for manufacturing an aluminum alloy wire used in an overhead power transmission line, and a product produced by the method. The non-aging aluminum alloy wire of the present invention includes the following ingredients in weight percentage: Mg 0.08-0.20%, Fe 0.10-0.25%, Cu0.05-0.18%, the sum of Ti, V, Mn, Cr elements≤0.01%, and the rest is Aluminum liquid. The conductivity of the aluminum alloy wire produced by the above alloy formula can reach 59%IACS, and the strength can reach 240-255MPa. The aluminum alloy wire stranded with this single wire has high conductivity, low resistance loss, good arc sag characteristics, and no hysteresis. Loss, overload performance and other characteristics.

Owner:QINGDAO HANHE CABLE

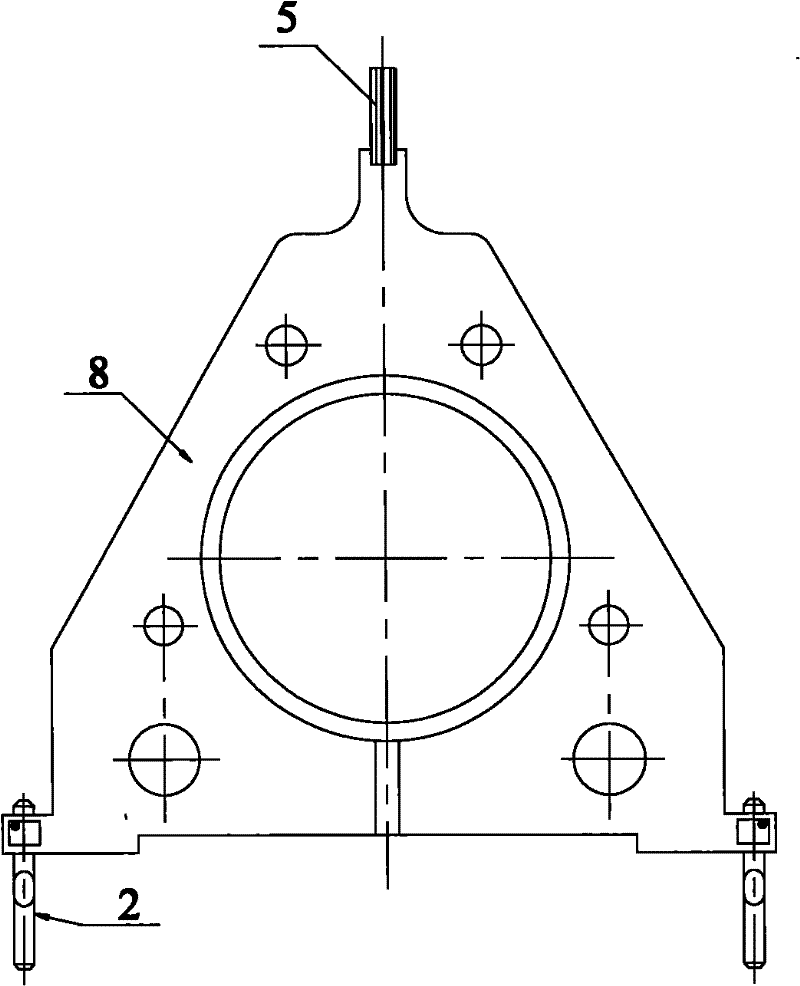

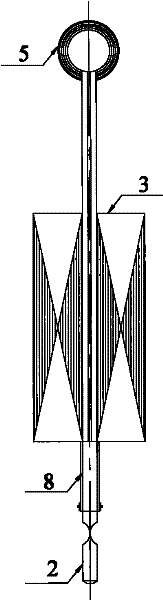

Flexible pendulous accelerometer

ActiveCN101592678BReduce stiffnessEliminate Coulomb frictionAcceleration measurement using interia forcesAccelerometerCoulomb friction

The invention discloses a flexible pendulous accelerometer, which comprises a shell, a flexible rod, a torquer moving coil, a torquer stator consisting of a yoke iron and a permanent magnet, a signal sensor consisting of a signal sensor moving coil and a signal sensor stator, a triangular pendulous reed and a servoamplifier, wherein the shell is full of a damping liquid; the triangular pendulous reed, the torquer moving coil and the signal sensor moving coil form a pendulum module; the flexible rod ensures that the pendulum module and an instrument shell are elastically connected; and the torquer stator and the torquer moving coil form a torquer. The flexible pendulous accelerometer eliminates the Coulomb friction force caused by a pivot and a jewelled bearing compared with the prior jewelled bearing supporting mode due to adopting a flexible supporting mode; the flexible supporting has small rigidity in a sensitive direction of the accelerometer and has large rigidity in other directions at the same time, which improves instrument measurement precision as well as vibration-resistant and shock-resistant abilities; the flexible pendulous accelerometer adopts a liquid for damping, and has better overload capacity and shock-resistant capability compared with a quartz flexible pendulous accelerometer adopting air damping.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com