Combine harvester with rotary stubble cutter

A combine harvester and rotating shaft technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of small distance from the working position to the ground, reduce the height of residual stubble, and the redundancy of structural strength, etc. The effect of small load, improved overload capacity, and convenience for subsequent farming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the specific implementation manners of the present invention will be further described in conjunction with the accompanying drawings.

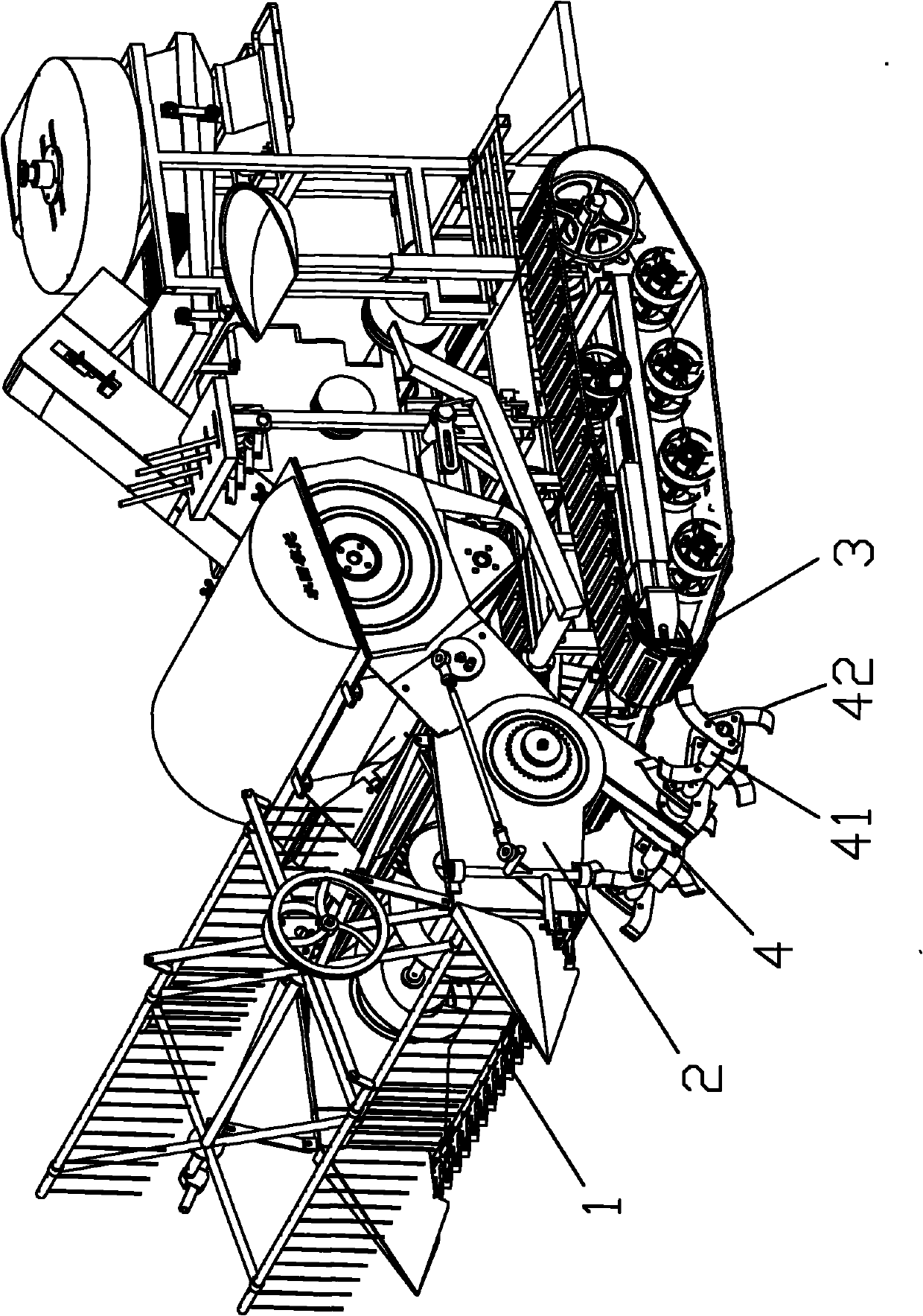

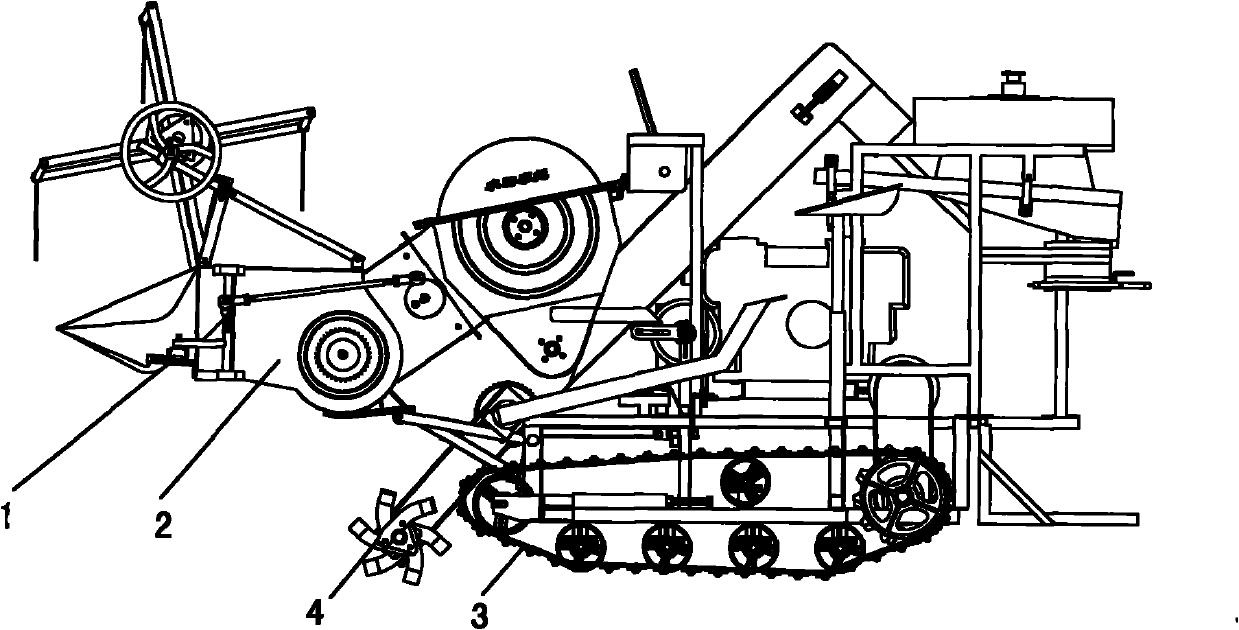

[0015] figure 1 , figure 2 An embodiment of the present invention is shown, a combine harvester with a rotary stubble breaker, comprising an upper cutter device 1, a traveling mechanism 2 and a header 3, and in front of the traveling mechanism 2, the upper cutter device 1 Rotary stubble breaker 4 is installed in the lower rear of the bottom, and the rotary stubble breaker 4 includes a rotating shaft 41 driven by power, and multiple groups of rotary blades 42 are fixedly installed on the rotating shaft 41 .

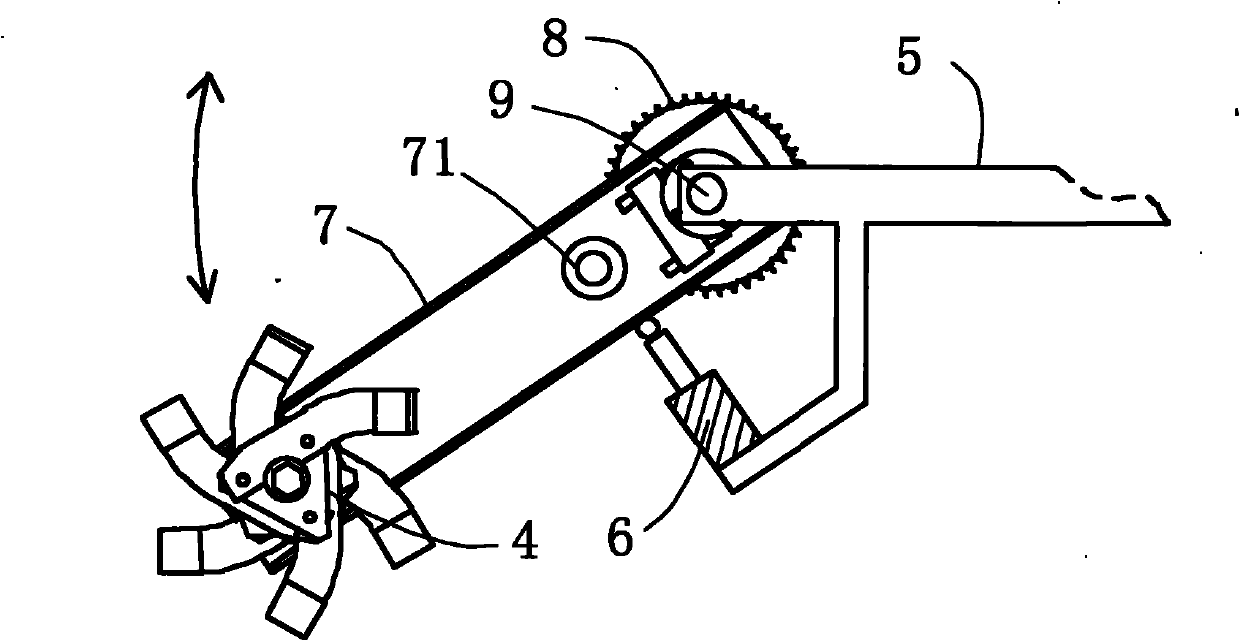

[0016] image 3 Another embodiment of the present invention is shown, a combine harvester with a rotary stubble breaker, the rotary stubble breaker 4 is installed on one end of the transmission box 7, and the other end of the transmission box 7 is articulated on the frame 5; The telescoping rod 6 bases are movable and hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com