Slotless permanent magnet motor

A permanent magnet motor and stator technology, applied in electric components, electromechanical devices, electrical components, etc., to achieve the effect of small size, stable operation and good acceleration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

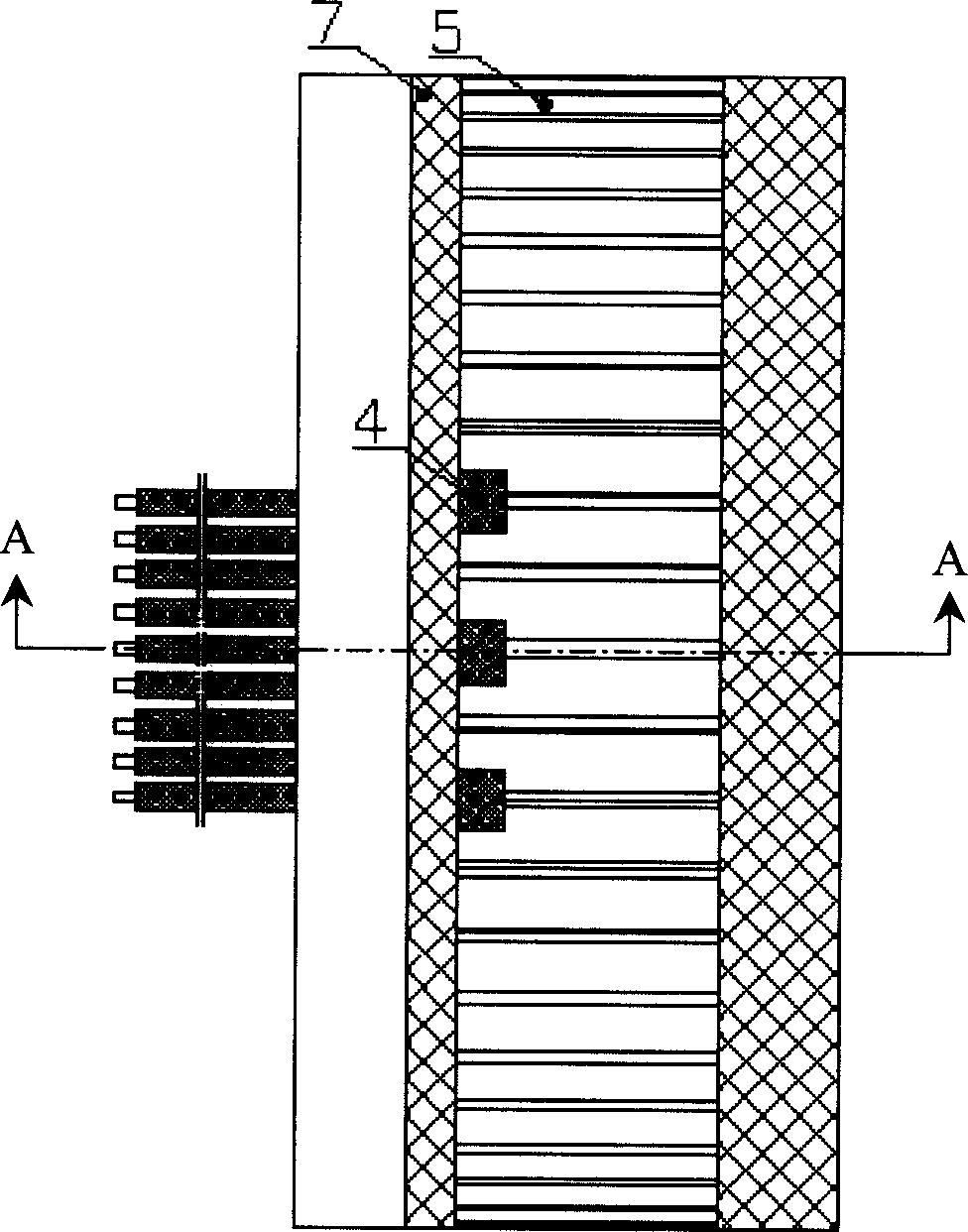

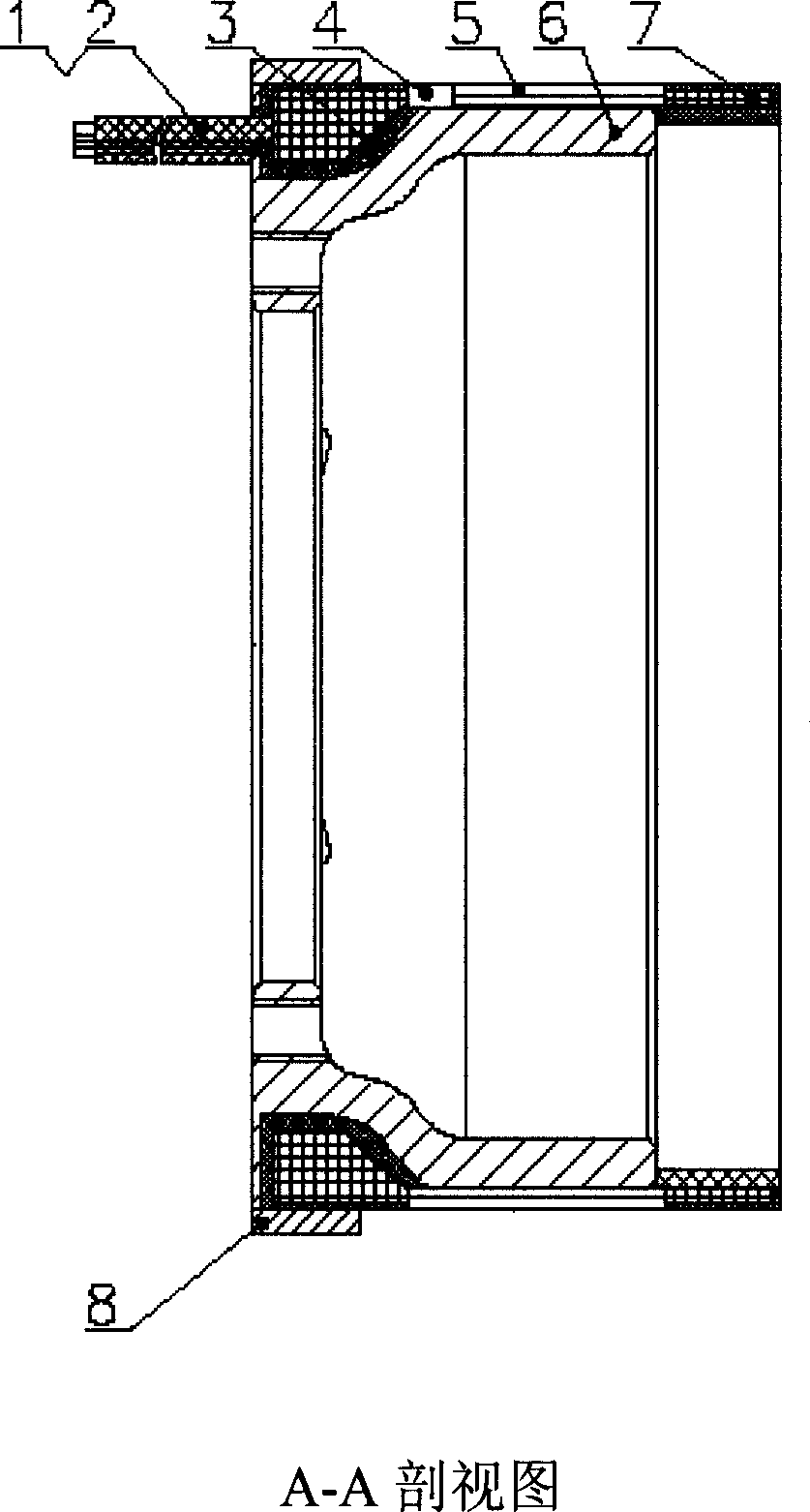

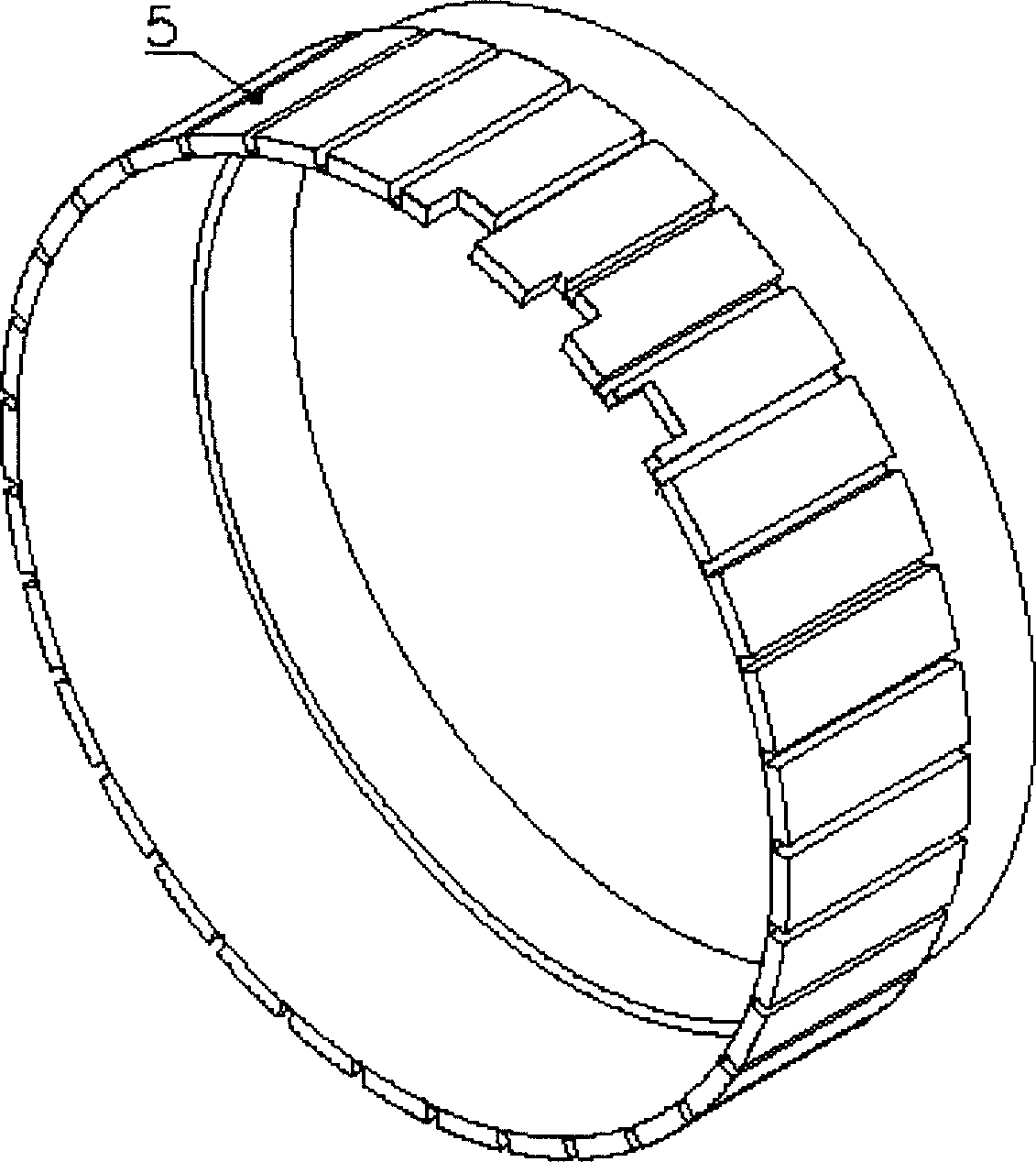

[0018] The improvement of the slotless permanent magnet motor in this embodiment is mainly on the stator assembly. like figure 1 , figure 2 It is a structural diagram of the stator assembly of the practical slotless permanent magnet motor. The stator assembly includes a dummy 5, an iron core 6, and a stator winding 7. The dummy 5 is set outside the iron core 6, and the aforesaid Stator windings 7 are routed outside said dummy stator 5 . Described dummy 5 is made of insulating material epoxy glass cloth board. like image 3 is the stereogram of hypothetical sub-5, such as Figure 4 It is a perspective view of the iron core 6.

[0019] The stator assembly also includes a pressure ring 8 , which is sleeved on one end of the stator winding 7 , and fixes the dummy stator 5 and the stator winding 7 on the iron core 6 .

[0020] After the stator winding 7 is fixed on the said dummy 5 with the press ring 8, it is sealed firmly with glue in vacuum.

[0021] The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com