Environment-friendly nanocomposite high polymer power cable

A nano-composite, power cable technology, used in power cables, insulated cables, cables, etc., can solve the problems that cables cannot guarantee safe operation, cannot adapt to safety performance, and safety performance is monotonous, so as to avoid hysteresis loss and improve mechanical performance. , to avoid the effect of insulation cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

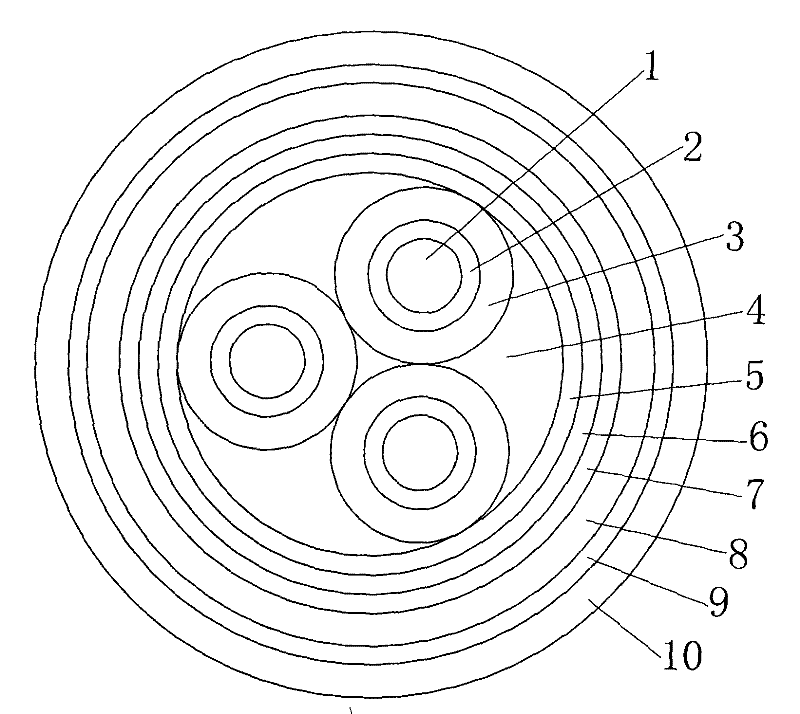

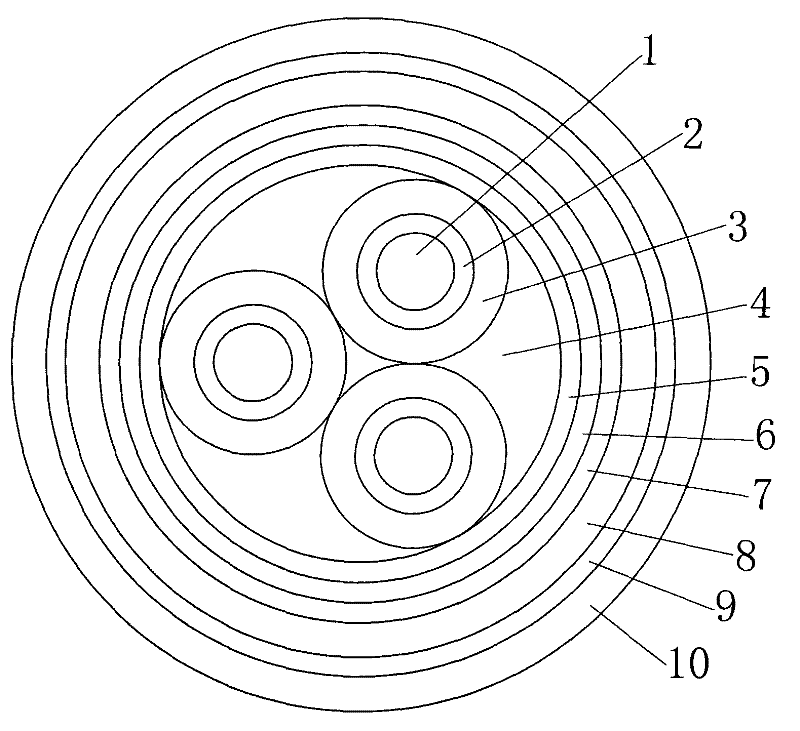

[0014] Example: figure 1 As shown, the environment-friendly nanocomposite high polymer power cable described in this embodiment, the conductor 1 adopts multiple strands of soft tinned copper wires of the fifth structure to be twisted into a conductive core, and the conductor production goes through the following steps: wire drawing-annealing Tinned-bundled wire-(multi-stranded), the conductor is in the form of bundled strands, with a cross-section of 6mm 2 The following conductors are in the form of bundles with a cross-section of 6mm 2 And above the conductor, due to the large cross-section, the number of conductor single wires is too much, and it needs to be re-twisted after bundled wires, of which 1mm 2 The maximum diameter of single wire in the following conductors is 0.21mm, 1.5-2.5mm 2 The maximum diameter of single wire in the conductor is 0.26mm, 4-6mm 2 The maximum diameter of single wire in the conductor is 0.31mm, 10-50mm 2 The maximum diameter of single wire in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com