Iron winding core for shell transformer and method

A technology for shell-type transformers and coiled iron cores, which is applied in the fields of coiled iron cores for transformers, coiled iron cores for shell-type transformers and their production, and can solve the problems of low lamination productivity, complicated wedging process, poor maintainability, etc., and achieve Strong short-circuit resistance, labor saving, and strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

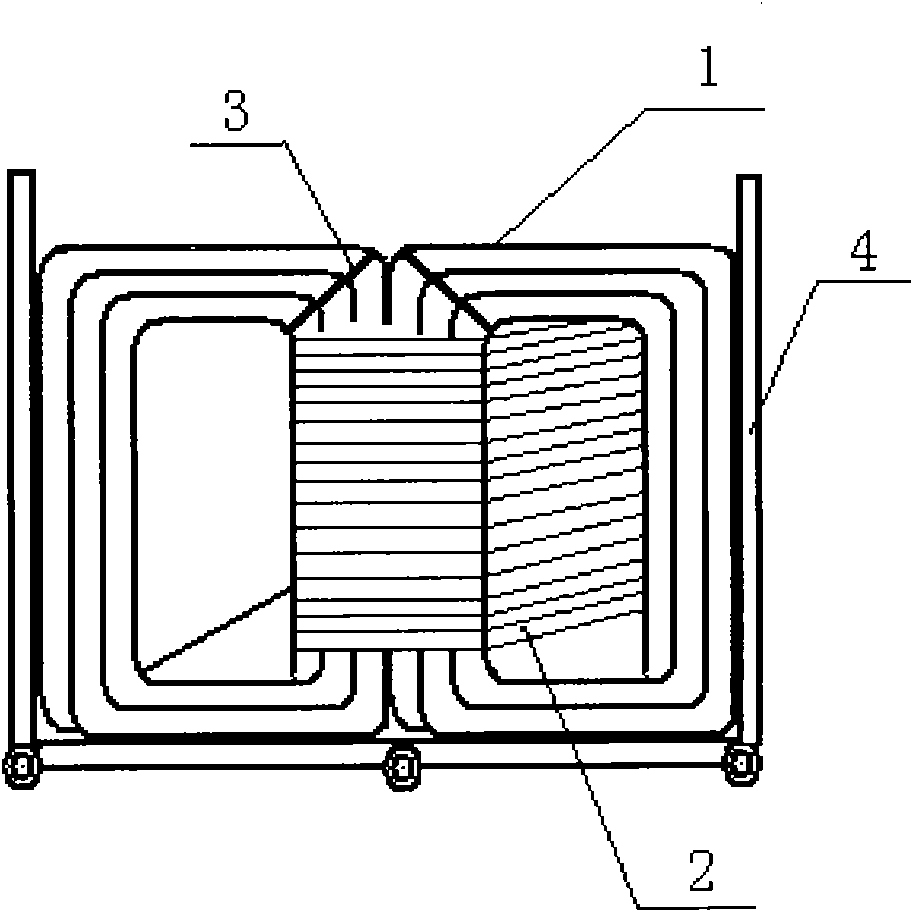

[0029] Such as image 3 , Figure 4 , Figure 5 As shown, the present invention consists of two rectangular wound iron cores 1 , binding straps 2 and interleaved windings 5 . A cutout 3 is arranged respectively above the binding band 2 on the two rectangular coiled iron cores 1, and the two cutouts are symmetrically distributed.

[0030] Concrete preparation method of the present invention, its steps are as follows:

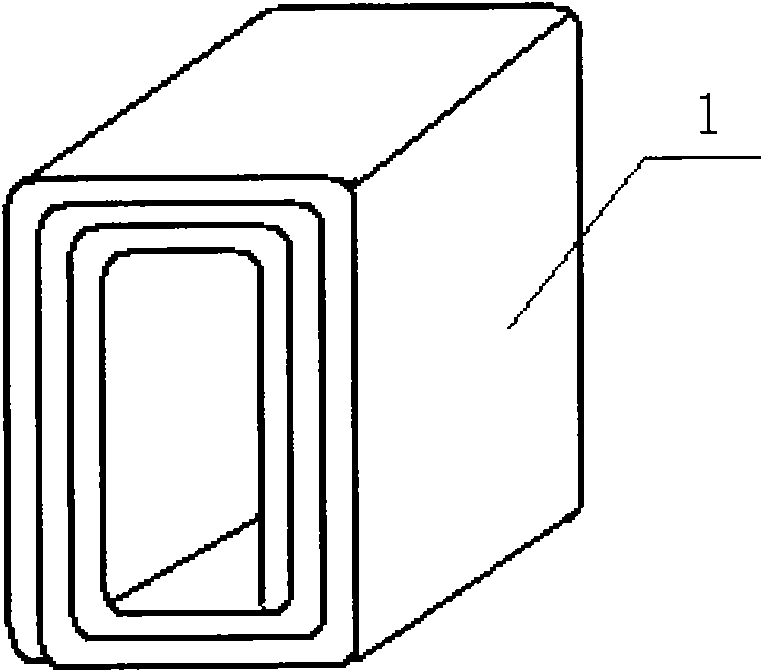

[0031] 1. Use specific mechanical equipment to roll the silicon steel strip into such figure 1 The rectangular coiled iron core 1 shown is subjected to annealing treatment;

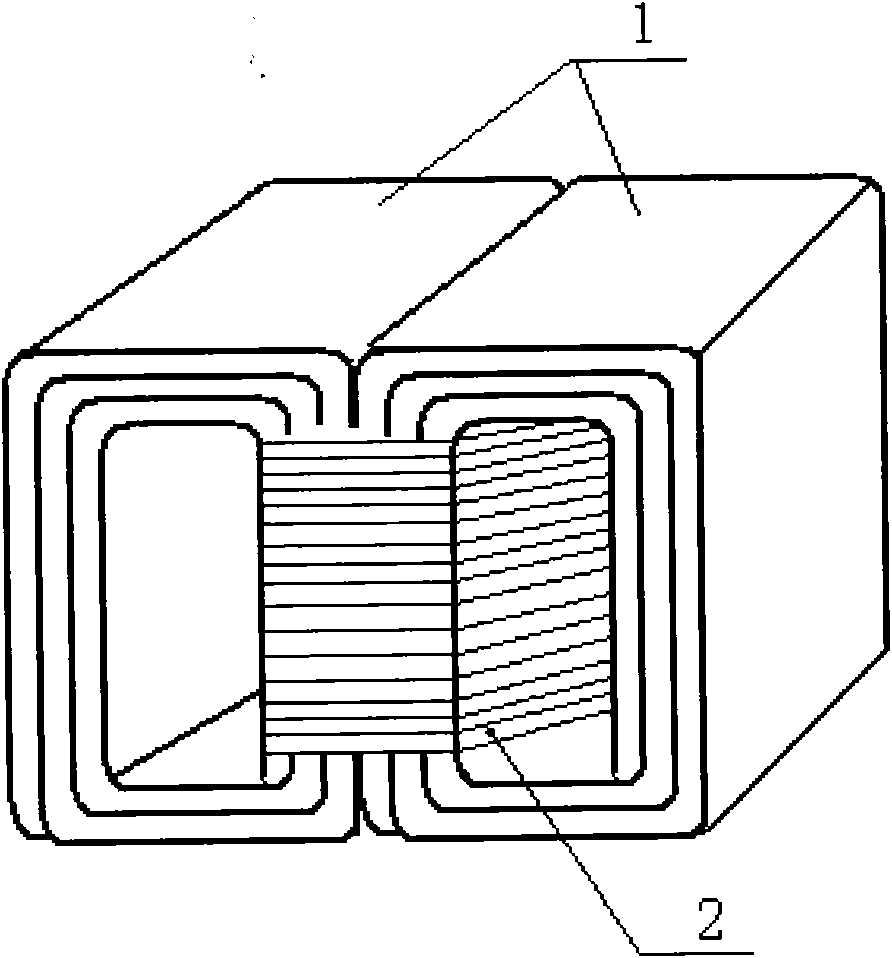

[0032] 2. If figure 2 As shown, the two rolled rectangular coiled iron cores 1 are bound together with a special binding band 2, and the binding part is cured with epoxy resin (other parts are not cured);

[0033] 3. If image 3 As shown, put the cured coiled iron core 1 on the specially customized tooling 4 by using lifting equipment; use a laser knife to make two incisions 3 at s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com