Flexible pendulous accelerometer

An accelerometer and pendulum technology, applied in the field of vehicle-mounted acceleration measurement components, can solve problems such as poor impact resistance and large overload capacity, increased system design, process difficulty, low tensile strength of quartz materials, etc., to achieve good overload capacity and resistance Effects of shock capability, elimination of Coulomb friction, improved performance and measurement accuracy, and resistance to vibration and shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

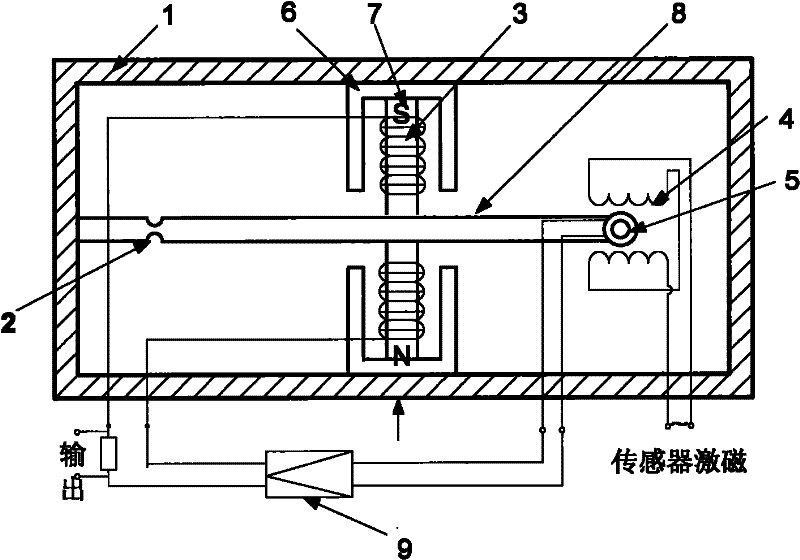

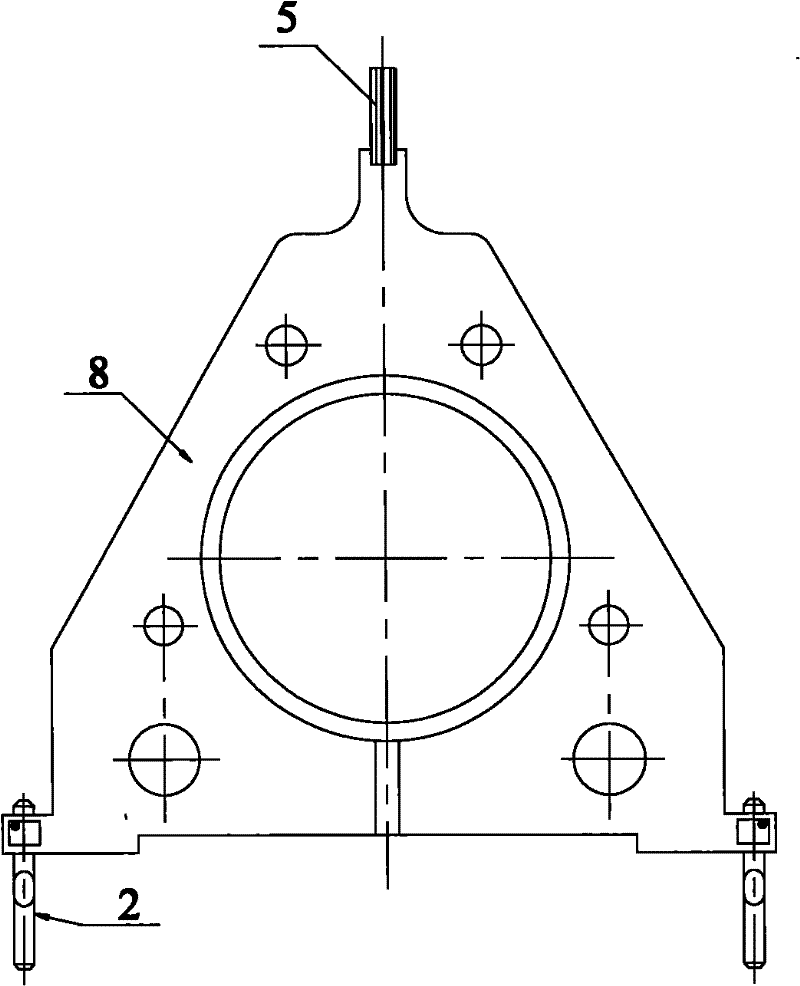

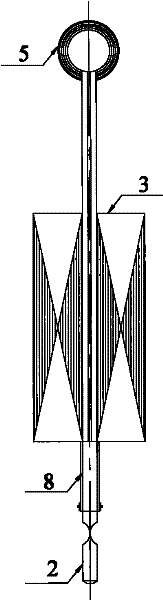

[0020] The invention is a typical force balance acceleration sensor, which is composed of a flexible pendulum assembly, a signal sensor, a push-pull permanent magnet torque device, a flexible rod, a control circuit and the like. Such as figure 1 As shown, this type of accelerometer mainly includes a housing 1, a flexible rod 2, a torque device moving coil 3, a torque device stator composed of a yoke 6 and a permanent magnet 7, and a signal sensor moving coil 5 and a signal sensor stator 4 The signal sensor, the triangular pendulum 8 and the servo amplifier 9 are filled with silicone oil as a damping liquid in the housing 1. The triangular pendulum 8, the torque device moving coil 3 and the signal sensor moving coil 5 form the pendulum assembly, the center position of the triangular pendulum 8 Install the torque device moving coil 3, install the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com