Method for manufacturing winding wires

A manufacturing method and winding wire technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as thick insulation, uneven insulation, and difficulty in soaking, and achieve good moisture and heat resistance, smooth surface, and easy soaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

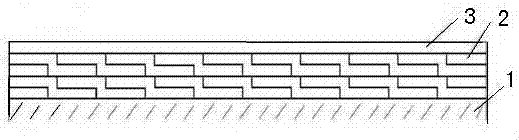

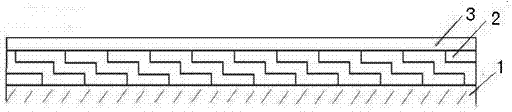

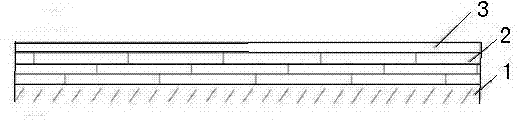

[0016] Depend on image 3 Known, a kind of manufacturing method of winding wire, comprises the following steps:

[0017] 1. Flat-wrap the first layer of mica tape; wrap the first layer of 0.08mm glass cloth with single-sided reinforcement tape 2, with the mica side facing inward, flat-wrap the TBR that meets the specified size after straightening, polishing, deburring, cleaning and drying type copper flat wire (1).

[0018] 2. Flat-wrap the second layer of mica tape; then flat-wrap the second layer of 0.08mm glass cloth single-sided reinforcement tape (2), with the mica facing inward, and the distance between the start of the second layer of mica tape and the first layer of mica tape About 5mm at the seam.

[0019] 3. Flat-wrap the third layer of mica tape; then flat-wrap the third layer of 0.08mm glass cloth single-sided reinforcing tape (2), with the mica facing inward, and the distance between the beginning of the third layer of mica tape and the first layer of mica tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com