Permanent-magnet synchronous traction motor for motor train

A traction motor and permanent magnet synchronous technology, applied in the field of electric motors, can solve problems such as unsuitable permanent magnet synchronous traction motors for bullet trains, structural defects of permanent magnet synchronous motors, etc., and achieve improved starting and overload capabilities, power density and utilization of magnet steel Improvement, application of a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

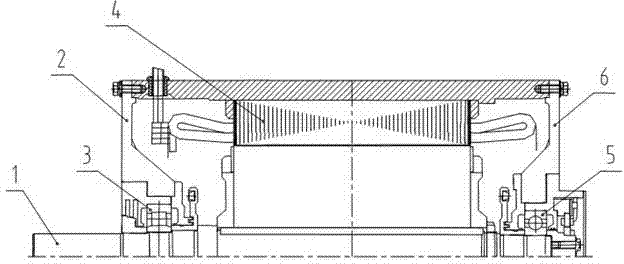

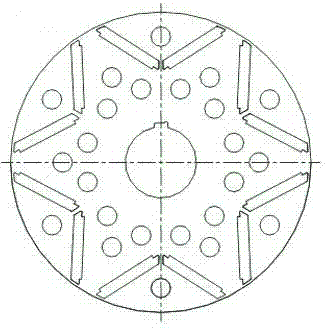

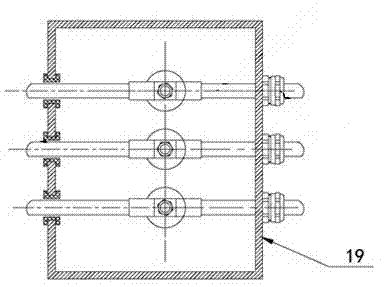

[0026] The permanent-magnet synchronous traction motor for motor vehicles includes a frame with an air inlet 16 on the top, a stator core 4 and a stator coil, a rotor assembly, and a junction box 19; the rotor assembly includes a rotating shaft 1 and a rotor core 11 formed by laminating rotor punches , rotor hold-down ring 8, permanent magnet baffle plate 10, magnetic steel groove 14 and ventilation holes are opened on the rotor punch, and magnetic steel 12 is inserted in the magnetic steel groove; the rotor hold-off ring 8 at the transmission end of the rotor assembly is provided with a ring-shaped rotor The dynamic balance groove is equipped with an inner seal ring labyrinth seal structure, and the permanent magnet baffle plate 10 at the drive end of the rotor assembly is set on the rotating shaft and pressed by the rotor pressure ring 8 . The rotor punching is a U-shaped magnetic circuit structure, that is, three magnetic steel grooves distributed in a U shape form a magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com