Electronic commutation electrically excited direct current motor

An electronic commutation, DC motor technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of large dispersion of permanent magnet materials, increased motor costs, and rising prices of magnetic steel and magnetic tiles, so as to improve the climb rate. Slope capacity and overload capacity, improve overload capacity, the effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

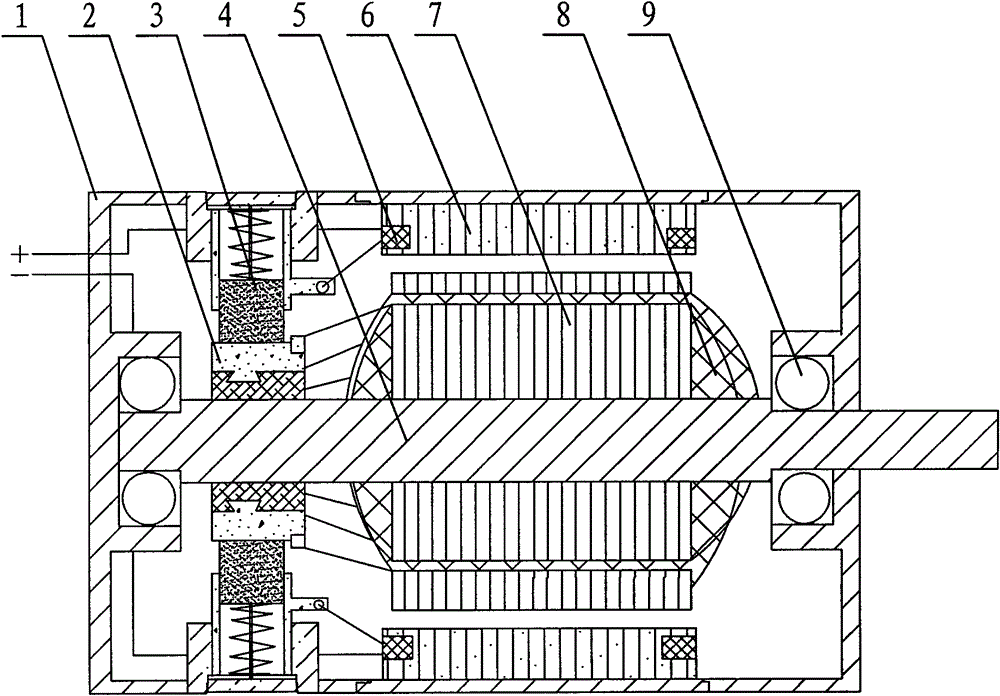

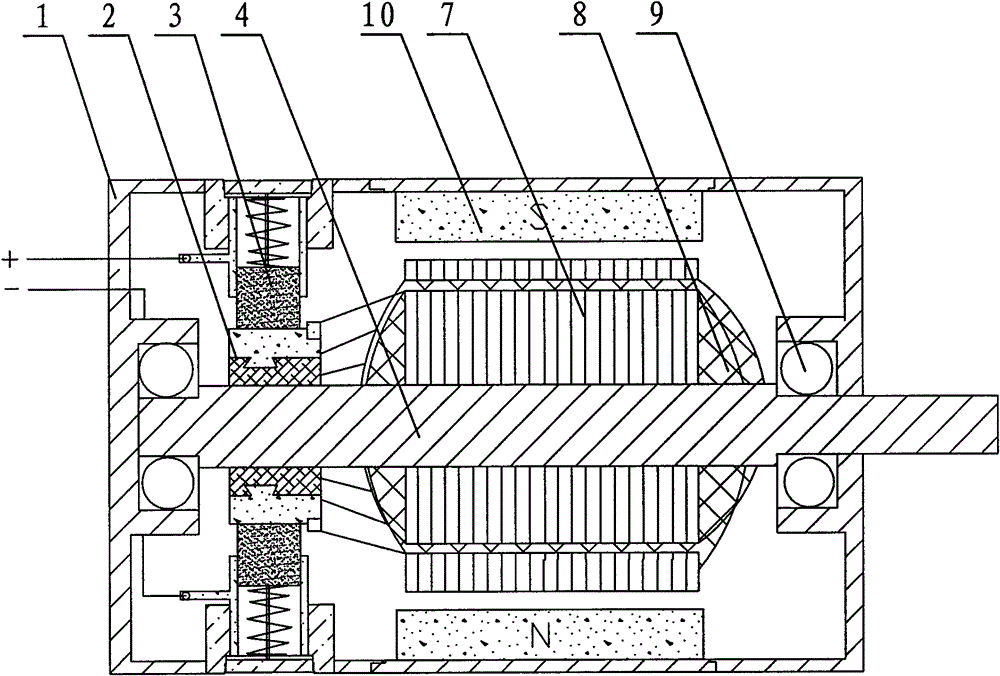

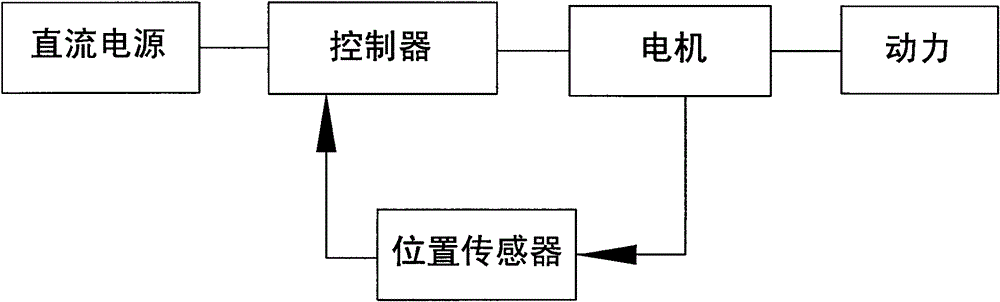

[0024] Figure 5 and Figure 6 Shown, for the present invention creates the first kind of specific embodiment of electronic commutation electric excitation DC motor, it comprises body 1, stator iron core 6, rotor iron core 7, rotating shaft 4, position sensor 11, sensing magnetic steel 15, The controller, the rotating shaft 4 is rotatably arranged on the body 1 through the bearing 9, the rotor core 7 is fixed on the rotating shaft 4, and the stator core 6 is provided with at least three sets of stator armature windings 12, and the rotor core 7 is At least one pair of rotor excitation windings 16 is provided, a collector ring 14 is fixed on the rotating shaft 4, a brush assembly 3 matched with the collector ring 14 is fixed on the body 1, and the two brushes of the brush assembly 3 are arranged on the circumference The same direction is in contact with the collector ring 14, of course, the two brushes can also be in contact with the collector ring 14 in the opposite direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com