Structural transformation control method in continuous cooling process of ultra-low-carbon wire rod of square billet

A technology of tissue transformation and cooling process, applied in the field of steel rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

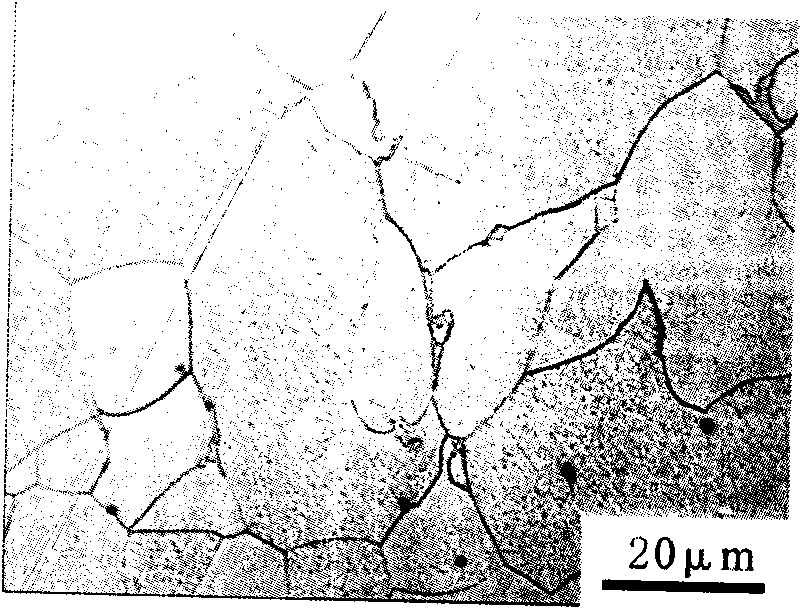

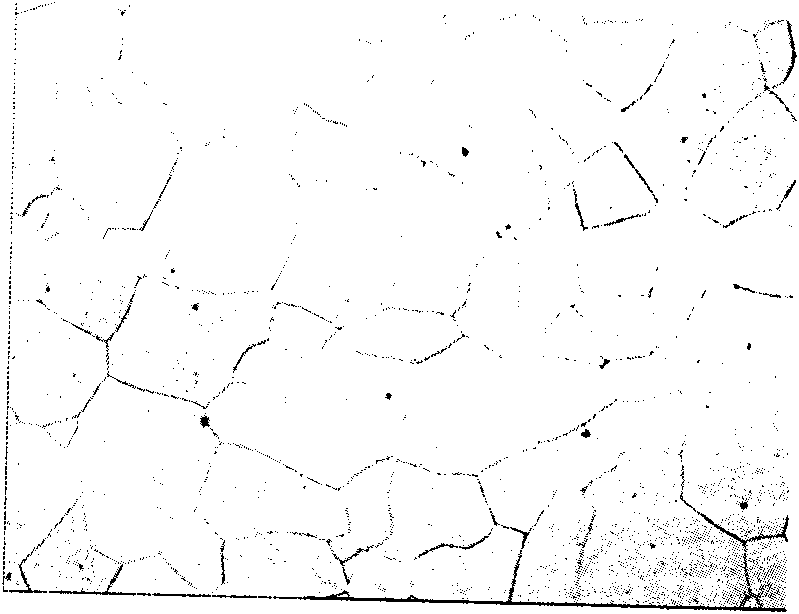

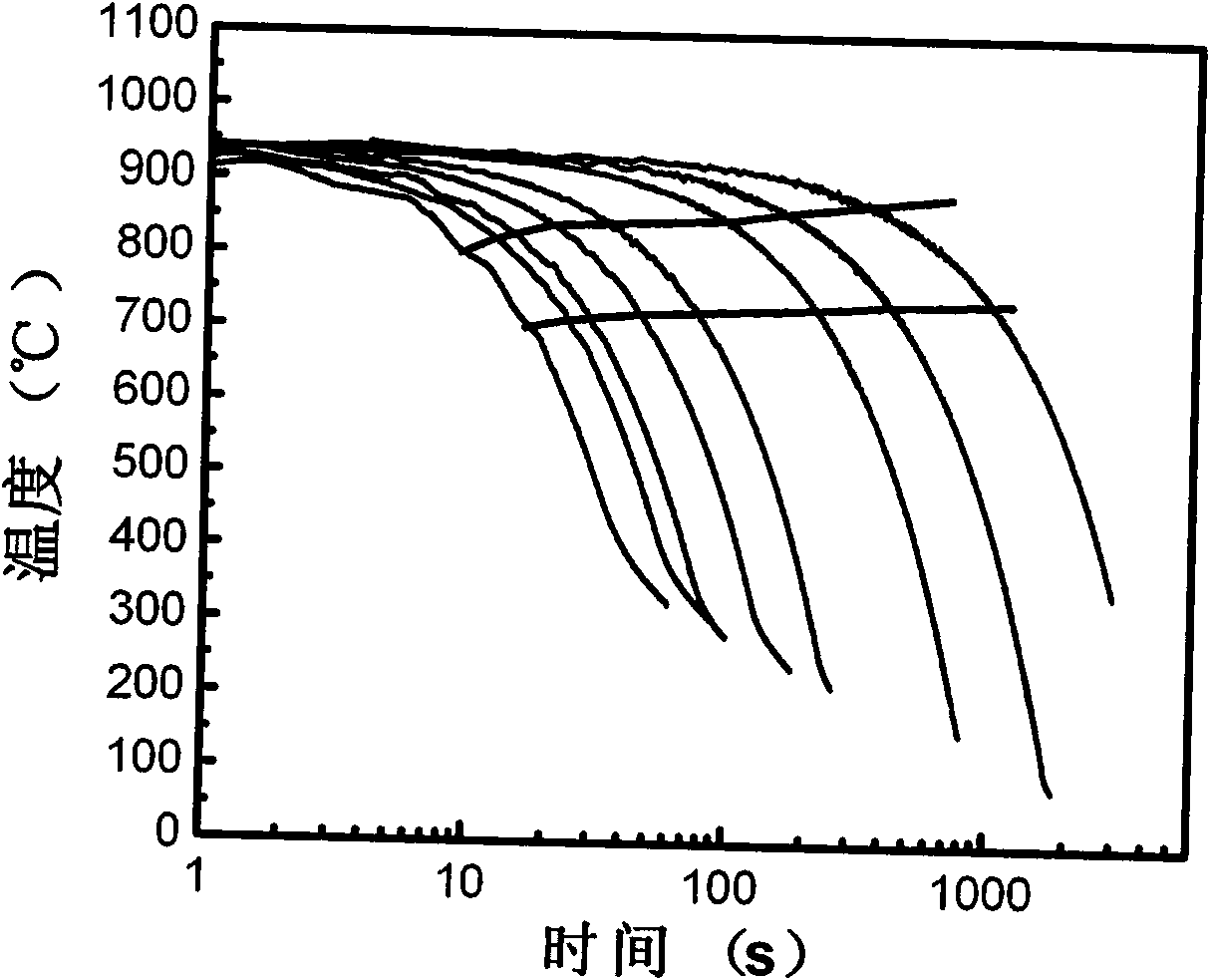

[0015] The invention is adopted in rolling production of high-quality ultra-low carbon steel SWRM6 wire rod in the first wire rod factory of Shougang. Adopt the cooling process of the present invention to mass-produce SWRM6 wire rods with specifications of ¢6.5mm that meet the requirements in Shougang, open the heat preservation cover after rolling, control the cooling rate at 5°C / s after rolling, and ferrite grain size at 10-15 μm , There is basically no tertiary cementite precipitation in the wire rod structure, the tensile strength of the wire rod is 320-350MPa, and the area reduction rate is greater than 75%, which meets the requirements of users and national standards, and is used for processing and producing copper-clad steel wire.

Embodiment 2

[0017] The invention is adopted in rolling production of high-quality ultra-low carbon steel SWRM6 wire rod in the first wire rod factory of Shougang. Using the cooling process of the present invention, SWRM6 wire rods with a specification of ¢6.5mm that meet the requirements are produced in batches in Shougang. After rolling, all heat preservation covers are closed, the cooling rate after rolling is controlled at 0.5°C / s, and the ferrite grain size is 20- 30μm, a large amount of tertiary cementite is precipitated at the grain boundary position in the wire rod structure, the tensile strength of the wire rod is 300-320MPa, and the area reduction rate is greater than 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com