Technique for producing high-strength copper covered steel conductor for coaxial cable inner core wire

A coaxial cable and production process technology, applied in the field of high-strength copper-clad steel conductors, can solve problems such as the great impact on the health of production workers, reduce the surface reduction rate of steel wires, and the brittleness of steel wires, so as to achieve the health protection of production workers, The effect of solving insufficient bonding force and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]A production process for high-strength copper-clad steel conductors for inner core wires of coaxial cables consists of the following steps:

[0049] (1) Rough drawing, ①Put the steel wire base material with a diameter of 6.5mm in the process of shelling and removing the oxide layer; ②Put the steel wire after removing the oxide layer into a high-speed continuous wire drawing machine and draw it to 3.4mm;

[0050] (2) Tempering at medium temperature. Put the roughly drawn steel wire into a vacuum tempering furnace for medium temperature heat treatment. The temperature of the furnace body is 400° C., the heating time is 2.5 hours, and the holding time is 5 hours.

[0051] (3) In addition to the oxide layer, ① pickle the heat-treated steel wire with industrial hydrochloric acid to remove the scale formed on the surface of the steel wire due to heat treatment, ② rinse the pickled steel wire with clean water to basically remove the acid on the surface of the steel wire. ③ Coat...

Embodiment 2

[0068] A production process for a high-strength copper-clad steel conductor used for the inner core wire of a coaxial cable. In the step (2) medium-temperature tempering process, the rough-drawn steel wire is put into a vacuum tempering furnace for medium-temperature heat treatment. The temperature is 550°C, the heating time is 2 hours, and the holding time is 3 hours. Other steps are the same as in Example 1.

Embodiment 3

[0070] A production process for a high-strength copper-clad steel conductor used for the inner core wire of a coaxial cable. In the step (2) medium-temperature tempering process, the rough-drawn steel wire is put into a vacuum tempering furnace for medium-temperature heat treatment. 500°C, the heating time is 2 hours, and the holding time is 4 hours. Other steps are the same as in Example 1.

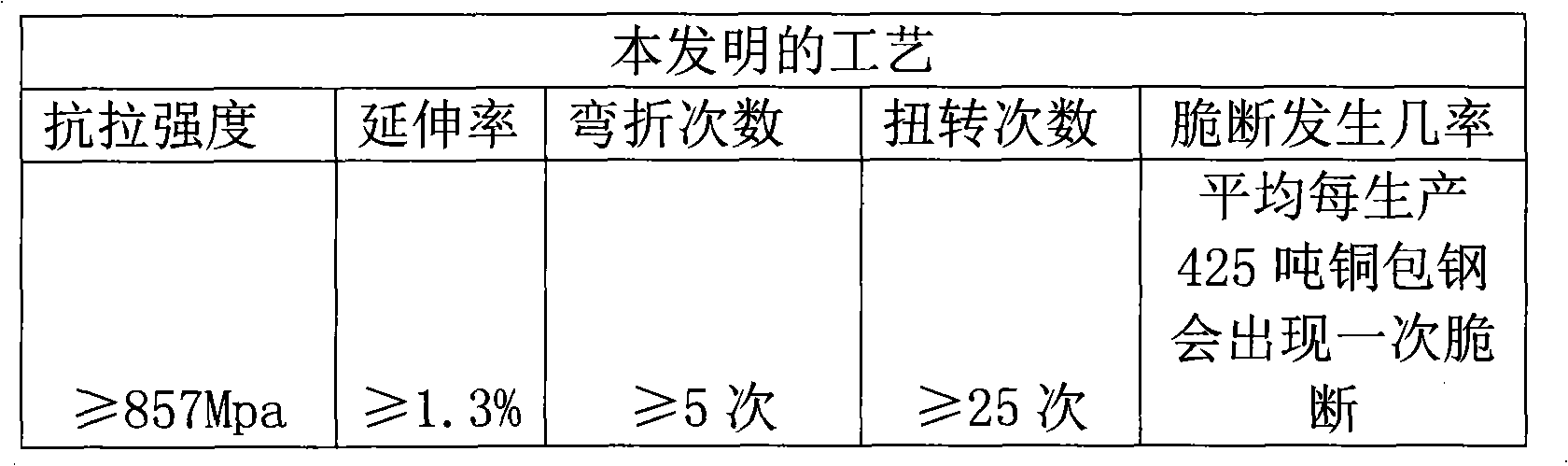

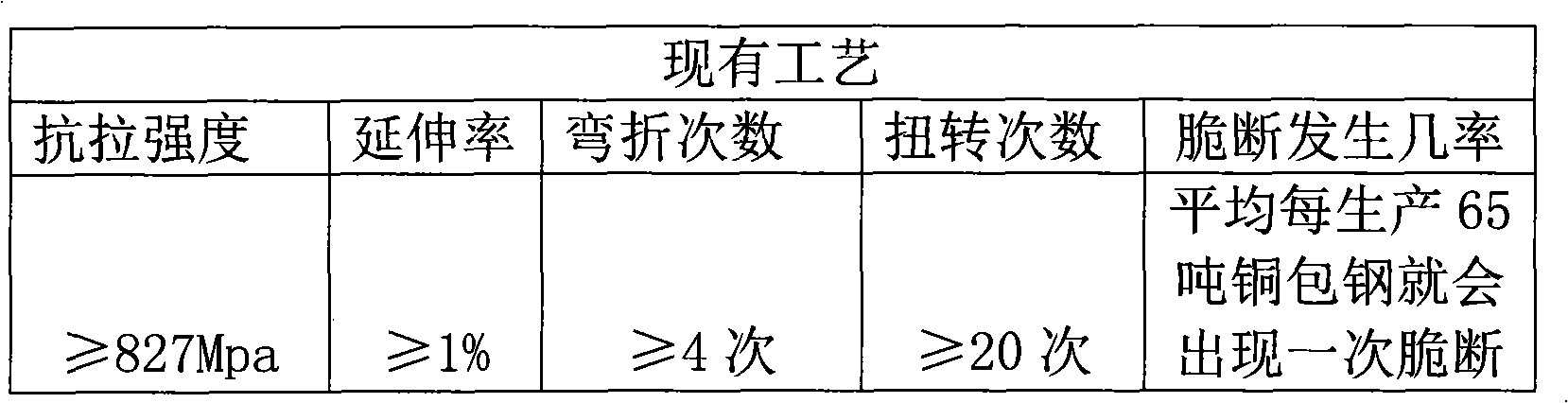

[0071] As shown in the above three embodiments, this process adds a medium temperature tempering process after the rough drawing process, and the tempering temperature is controlled between 400-550 °C. When the tempering temperature is too high, the martensite inside the steel wire will completely transform. If the tempering temperature is too low, the internal stress cannot be completely eliminated, and the problem of brittle fracture cannot be eliminated. The operating temperature of the anti-oxidation process in the above steps (12) and (16) is controlled between 40-60°C. The main co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com