Method for preparing copper-clad steel composite material

A composite material and copper-clad steel technology, which is applied in the manufacture of cables/conductors, electrical components, root rods/rods/wires/strip conductors, etc., can solve the problems of low yield, poor bonding strength of copper-clad steel composite materials, and production efficiency low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

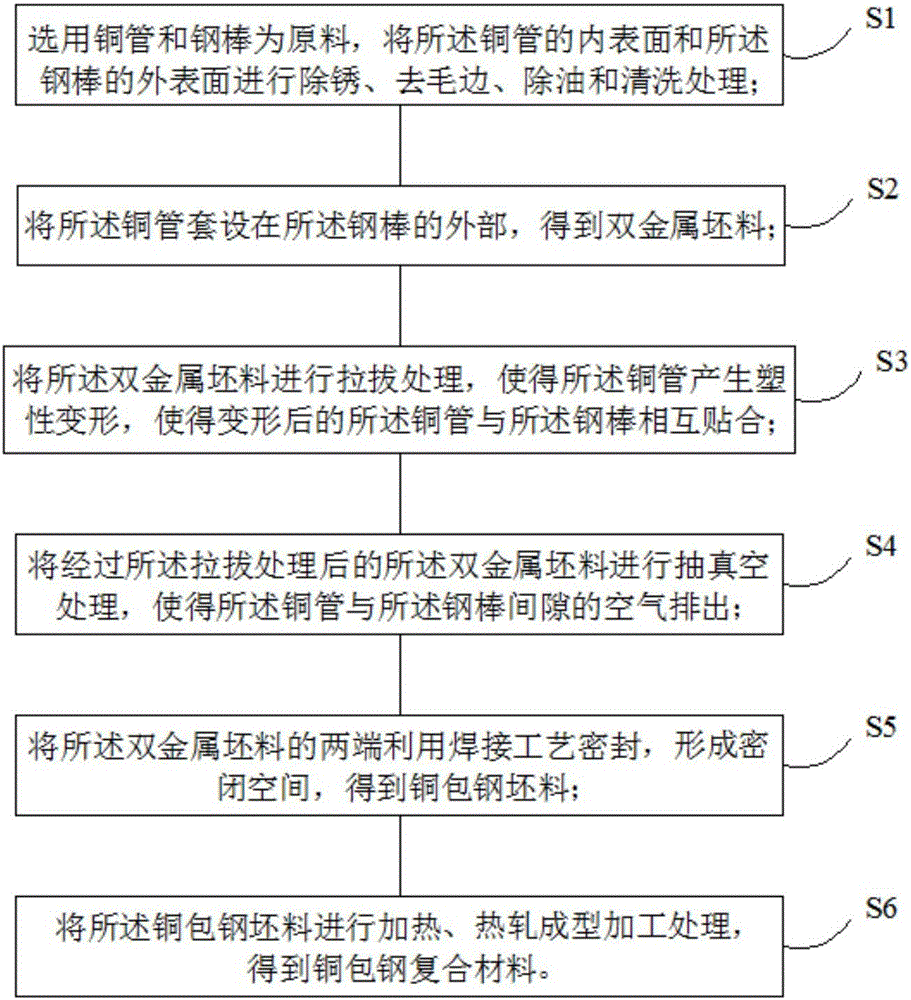

[0041] see figure 1 , the embodiment of the present invention provides a method for preparing a copper-clad steel composite material, which specifically includes the following steps:

[0042] S 1. Select copper pipe 3 and steel rod 4 as raw materials, and carry out derusting, deburring, degreasing and cleaning treatments on the inner surface of the copper pipe 3 and the outer surface of the steel rod 4;

[0043] S2. Set the copper pipe 3 on the outside of the steel rod 4 to obtain a bimetal blank;

[0044] S3, drawing the bimetal blank, so that the copper tube 3 is plastically deformed, so that the deformed copper tube 3 and the steel rod 4 are attached to each other;

[0045] S4, vacuumizing the bimetal blank after the drawing process, so that the air in the gap between the copper tube 3 and the steel rod 4 is discharged;

[0046] S5. Sealing the two ends of the bimetal blank by welding process to form a closed space to obtain a copper-clad steel blank;

[0047] S6, heating ...

Embodiment 1

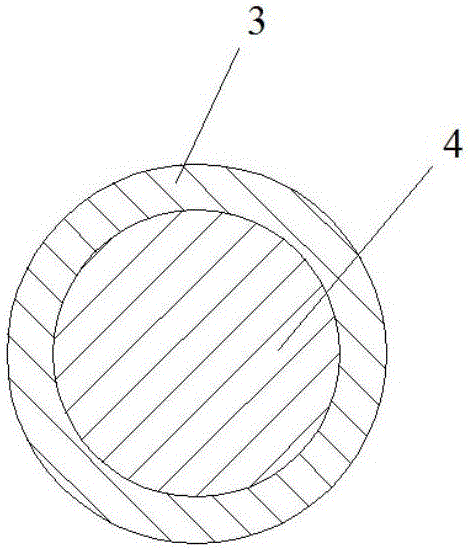

[0080] Such as figure 2 and Figure 4 As shown, in this embodiment, a circular copper tube 3 made of copper, with a diameter of Ф150 mm and a wall thickness of 3 mm is selected as the outer layer cladding material, and a Q235 circular steel rod 4 made of low carbon steel with a diameter of Ф140 mm is selected as the inner core material , the length of the copper tube 3 is greater than or equal to the length of the steel rod 4, so that the copper tube 3 can completely wrap the steel rod 4. The inner and outer surfaces of the copper pipe 3 and the outer surface of the steel rod 4 are cleaned by mechanical processing and chemical methods to remove dirt such as burrs, rust spots, oil stains, waste chips and organic matter.

[0081] Under normal temperature environment, use pressure equipment to put steel rod 4 into hollow copper tube 3 to obtain bimetallic blank; then draw copper tube 3 through variable diameter die and drawing equipment, so that the outer diameter of copper tube ...

Embodiment 2

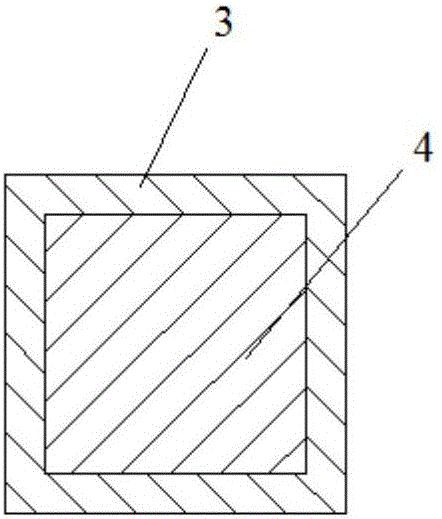

[0084] Such as image 3 , Figure 5 and Figure 6 As shown, the present embodiment selects a copper alloy material, a width of 120 mm, and a square copper tube 3 with a wall thickness of 5 mm as the outer cladding material, and selects a low-alloy steel material and a width of 105 mm as a Q235 square steel rod 4 as an inner core material. The length of the copper pipe 3 is greater than or equal to the length of the steel rod 4, so that the copper pipe 3 can completely wrap the steel rod 4. The inner and outer surfaces of the copper pipe 3 and the outer surface of the steel rod 4 are cleaned by mechanical processing and chemical methods to remove dirt such as burrs, rust spots, oil stains, waste chips and organic matter.

[0085] Under normal temperature environment, use pressure equipment to put steel rod 4 into hollow copper tube 3 to obtain bimetallic blank; then draw copper tube 3 through variable diameter die and drawing equipment, so that the outer diameter of copper tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com