Nickel/silver-coated copper-clad steel conductor core for special cable and manufacturing method thereof

A technology of silver-plated copper-clad steel and special cables, which is applied in the fields of medical equipment, aerospace, and electronics. It can solve problems such as discoloration, increase product manufacturing costs, and yellow appearance, and achieve strong corrosion resistance, high temperature resistance, and The effect of saving metallic silver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

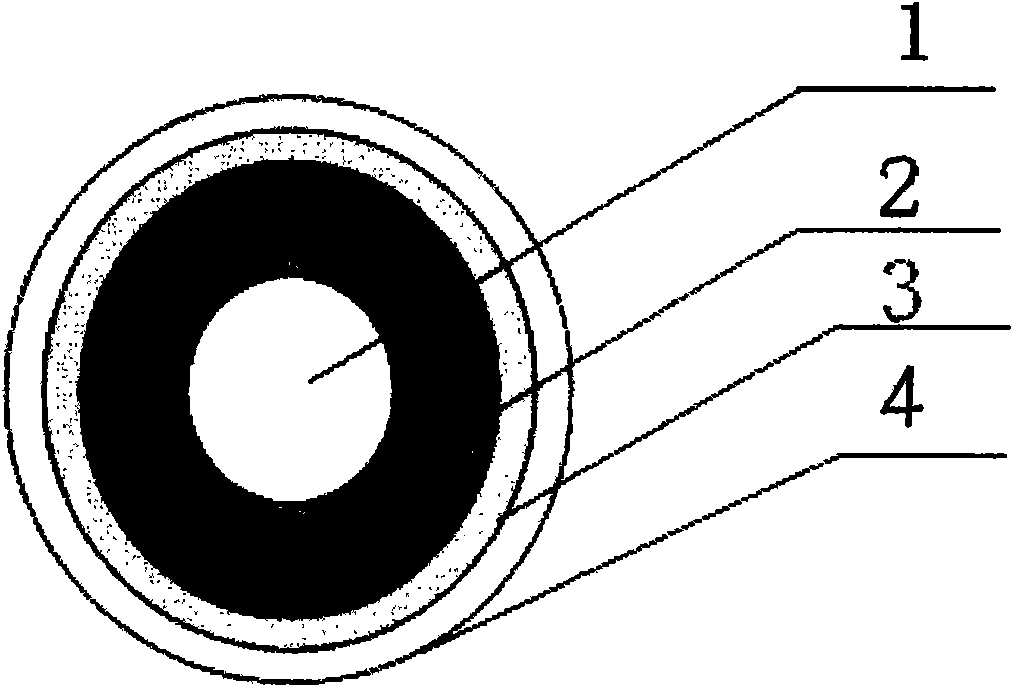

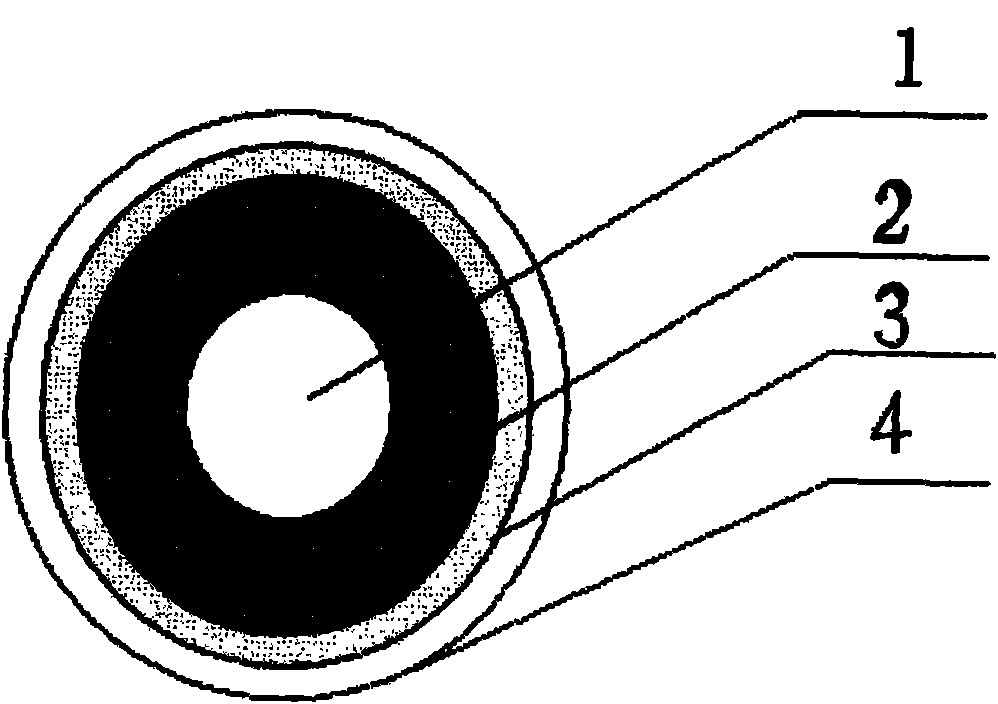

[0012] exist figure 1 Among them, the present invention is a nickel-plated silver-plated copper-clad steel conductor core for special cables. Its wire body is composed of several single wires, and the several single wires are connected by regular twisting or bundle twisting to form the wire body. Each single wire includes four layers of metal layers in turn, wherein the inner layer is the base material 1, the base material 1 is carbon structural steel, the second layer is the copper layer 2, and the outermost layer is the silver layer 4, between the copper layer (2) and A nickel layer 3 is provided between the silver layers 4 .

[0013] The invention also discloses a method for making a nickel-plated silver-plated copper-clad steel conductor core for a special cable, which is characterized in that it includes the following steps: Step 1: select carbon structural steel as the base material 1, and make the base material 1 Electrolytic copper plating; step 2, the base material 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com