Surface cleaning system for copper-clad steel wire

A surface cleaning and copper-clad steel wire technology, applied in cleaning methods and tools, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as inability to guarantee cleaning quality and affecting the electrical conductivity of copper-clad steel wire products , achieve high cleaning efficiency, excellent cleaning effect, and improve electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

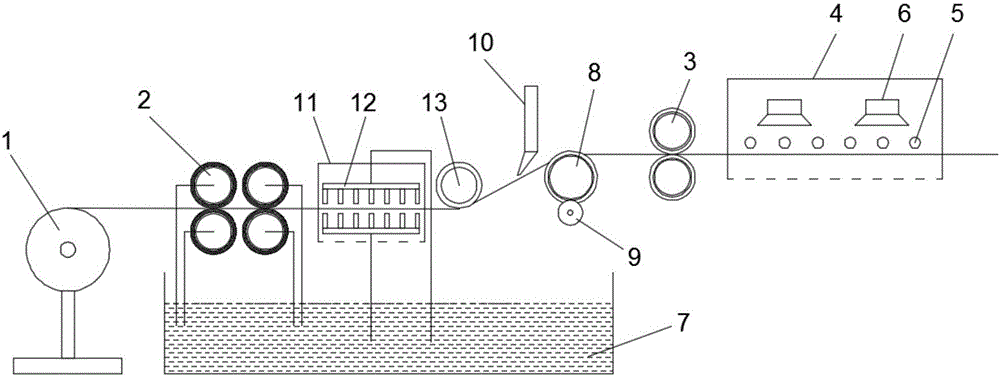

[0011] Such as figure 1 As shown, this embodiment provides a copper-clad steel wire surface cleaning system, which is sequentially arranged from left to right with a pay-off device 1, a steel brush double roller 2, a wire drawing device 3, and a drying device 4; A cleaning liquid tank 7 is provided under the roller 2; the cleaning liquid enters the steel brush double roller 2 from the cleaning liquid tank 7 through a pipeline; a spray cleaning device is also provided between the steel brush double roller 2 and the wire drawing device 3 11. The tension control roller 13 and the sponge roller 8; the sponge roller 8 is located at the upper right of the tension control roller 13, so that the steel wire between the tension control roller 13 and the sponge roller 8 is inclined upward; The bottom side of the roller 8 is provided with a squeezing roller 9; the squeezing roller 9 is located above the cleaning liquid tank 7; a water blowing fan 10 is provided above the steel wire between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com