Method for producing silver-copper plated steel clad wire for coated electronic product

A technology of silver-plated copper-clad steel and electronic products, applied in the direction of cable/conductor manufacturing, application, circuit, etc., can solve the problem of low resistivity performance of copper and steel bimetallic alloy, improper cladding process, silver-plated layer and copper-clad Problems such as poor steel penetration force, to achieve the effect of low resistance, high strength and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

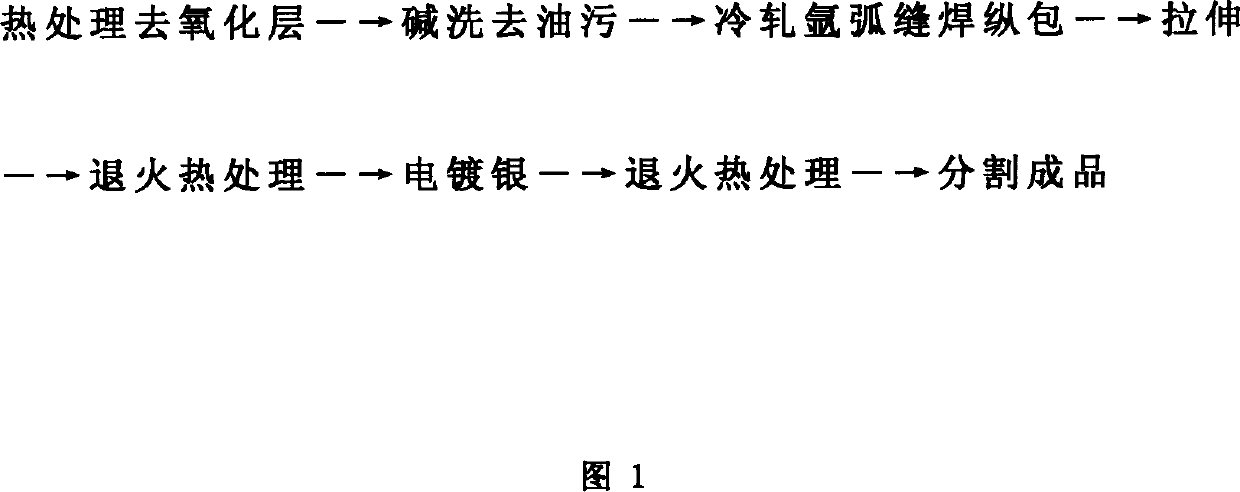

[0018] Embodiment: as shown in Figure 1, a kind of manufacturing method of silver-plated copper-clad steel wire for covered electronic product comprises the following steps:

[0019] (1) heat treatment to remove the oxide layer on the copper strip and steel wire surface;

[0020] (2) Alkali washing to remove oil stains on the surface of copper strips and steel wires;

[0021] (3) Cold-rolled argon arc seam welding of the copper strip, and longitudinally wrapping it on the steel wire;

[0022] (4) stretching;

[0023] (5) Annealing heat treatment;

[0024] (6) Electroplating silver on the surface of the copper-clad steel wire;

[0025] (7) Annealing heat treatment;

[0026] (8) Divide the finished product.

[0027] The cladding technology of the copper-clad steel wire in the present invention adopts the cold-rolled argon arc seam welding method, so that the copper strip is tightly longitudinally wrapped on the steel wire, and the copper molecules are re-contacted and mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com