Semiconductor device, manufacturing method thereof and electronic equipment

A manufacturing method and technology of electronic equipment, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve problems such as leakage current and affecting refresh characteristics of semiconductor devices, so as to suppress leakage current, satisfy conductivity, and suppress leakage current the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

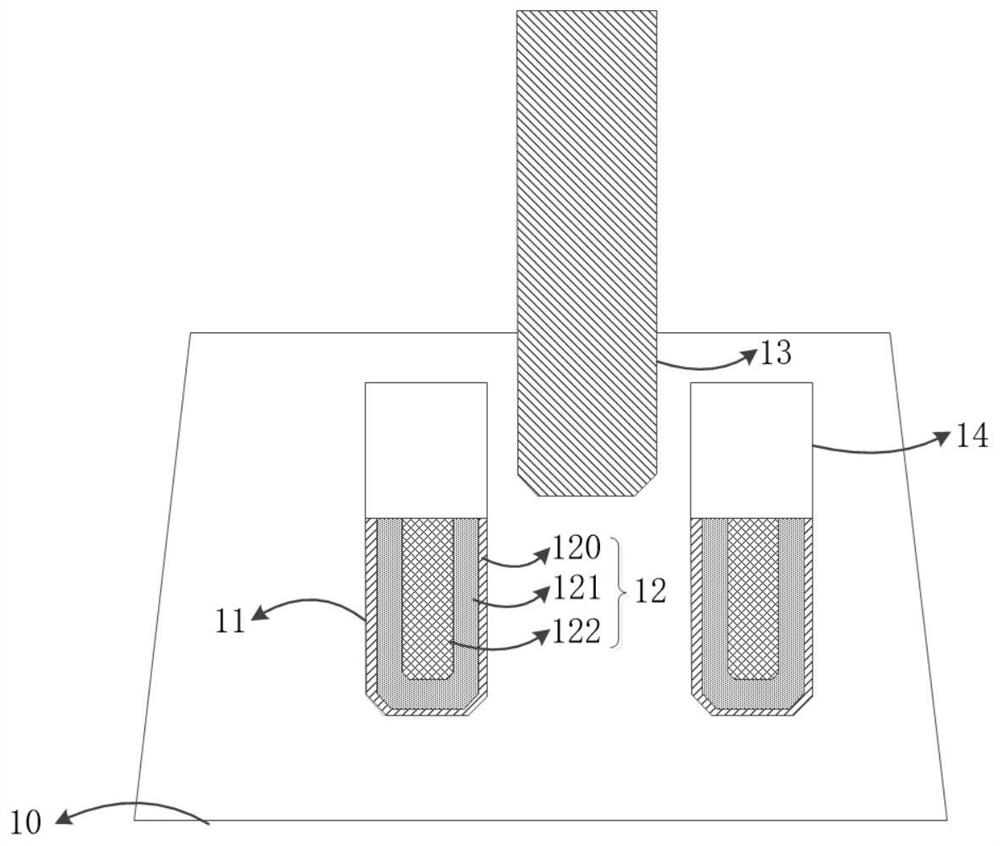

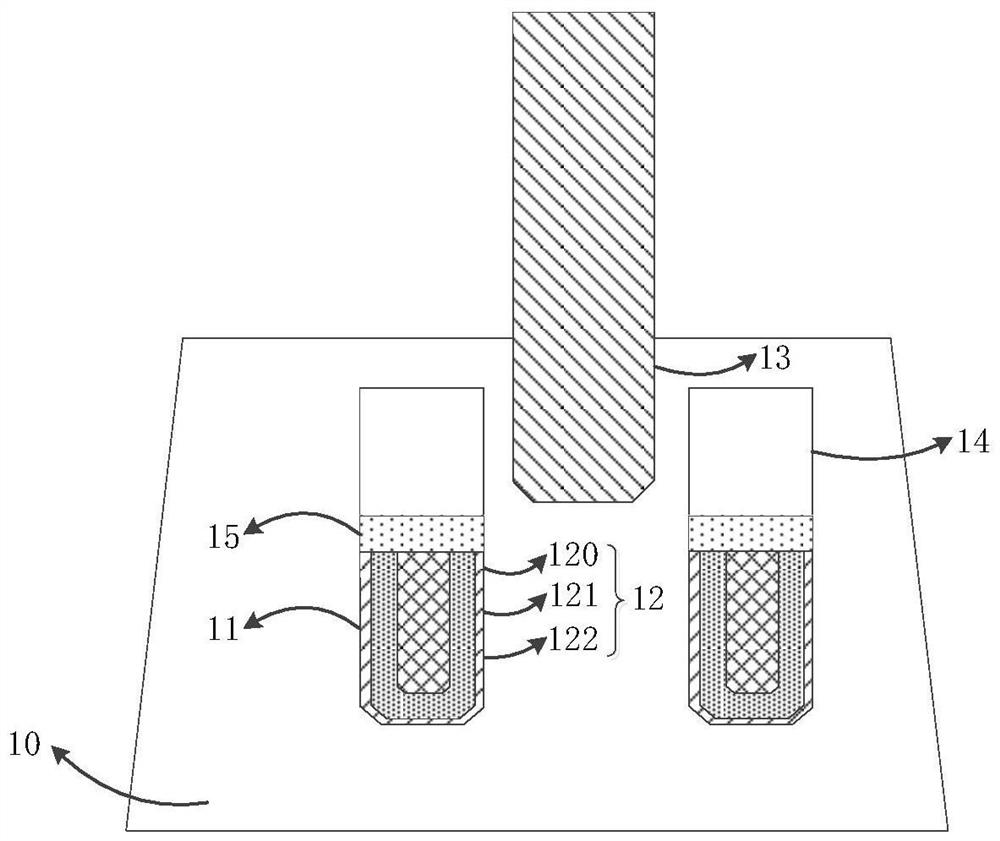

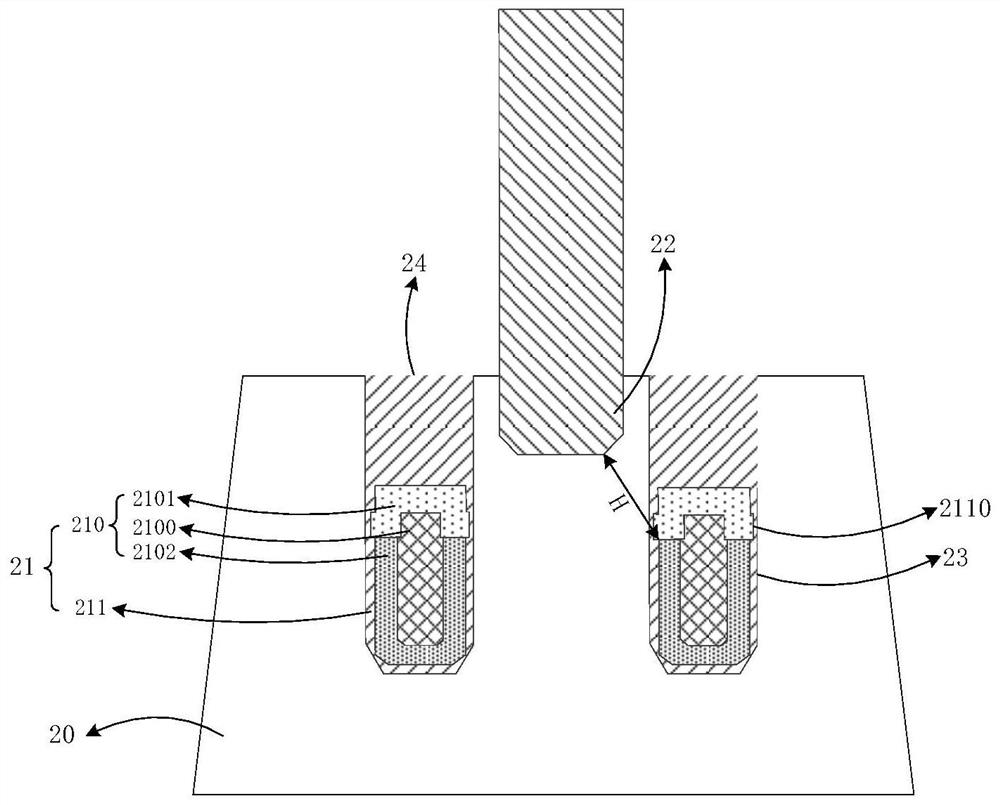

[0029] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

[0030] Various schematic diagrams of the embodiments of the present invention are shown in the drawings, which are not drawn to scale. Among them, in order to clearly understand the purpose, some details are enlarged and certain details may be omitted. The relative size of the various regions, layers shown in the figures, the relative size thereof, the positional relationship is merely exemplary, and in practice, it may deviate due to manufacturing tolerances or technical limits, and those skilled in the art according to actual The required area / layer having different shapes, sizes, relative positions can be designed.

[0031] Hereinafter, the term "first", "second" or the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com