Grey conductive silver paste for automobile glass and preparation method thereof

A technology of conductive silver paste and automotive glass, applied in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of lack of anti-oxidation performance, affecting the quality of automotive glass products, and storage of automotive glass products The time can't be too long and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

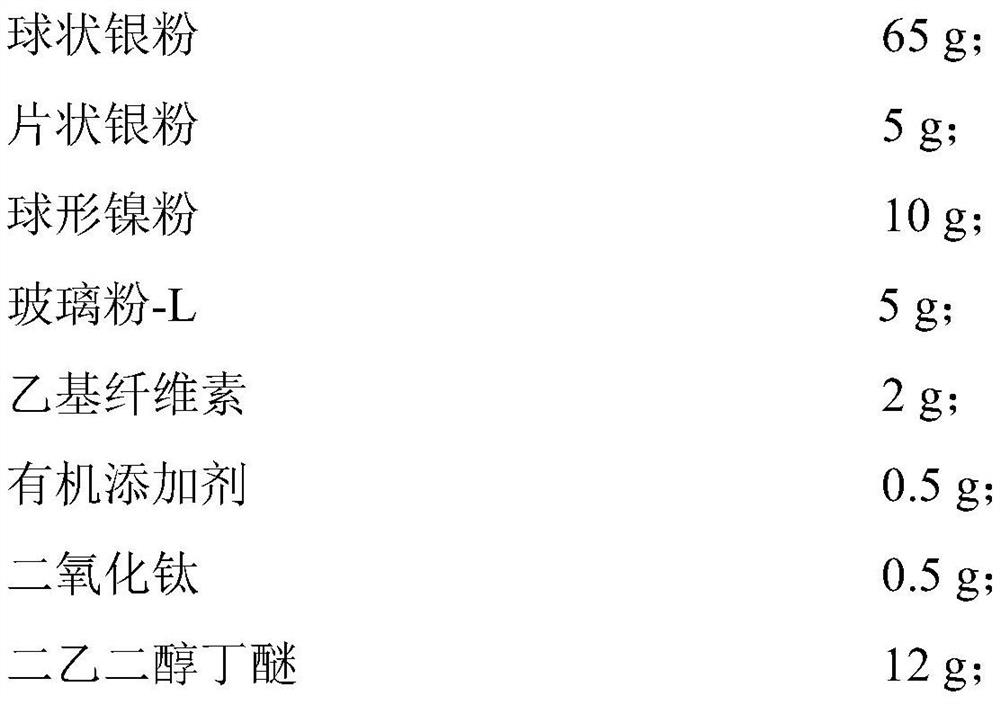

[0032] (1) Prepare 100g of raw materials, prepare raw materials according to the following components and quality:

[0033]

[0034] The particle size of the spherical silver powder used is 2.3 μm, and the tap density is 3.2 g / ml; the particle size of the flake silver powder is 6 μm, and the tap density is 2.4 g / ml;

[0035] The particle size of the spherical nickel powder used is 2.5 μm, and the tap density is 2.8 g / ml;

[0036] The composition and percentage of glass powder-L used are: 65% Bi 2 o 3 , 18%B 2 o 3 , 9% ZnO, 4% SiO 2 , 2%Al 2 o 3 , 1%Na 2 O, 0.5% Fe 2 o 3 , 0.5% ZrO 2 ;

[0037] The organic additives used are 0.25g dibutyl phthalate and 0.25g silane coupling agent KH550.

[0038] The titanium dioxide used was of analytical grade.

[0039] (2) Preparation of carrier: Weigh ethyl cellulose and diethylene glycol butyl ether, then heat it up to 80°C and keep the temperature constant. After the ethyl cellulose is completely dissolved, filter it on a mes...

Embodiment 2

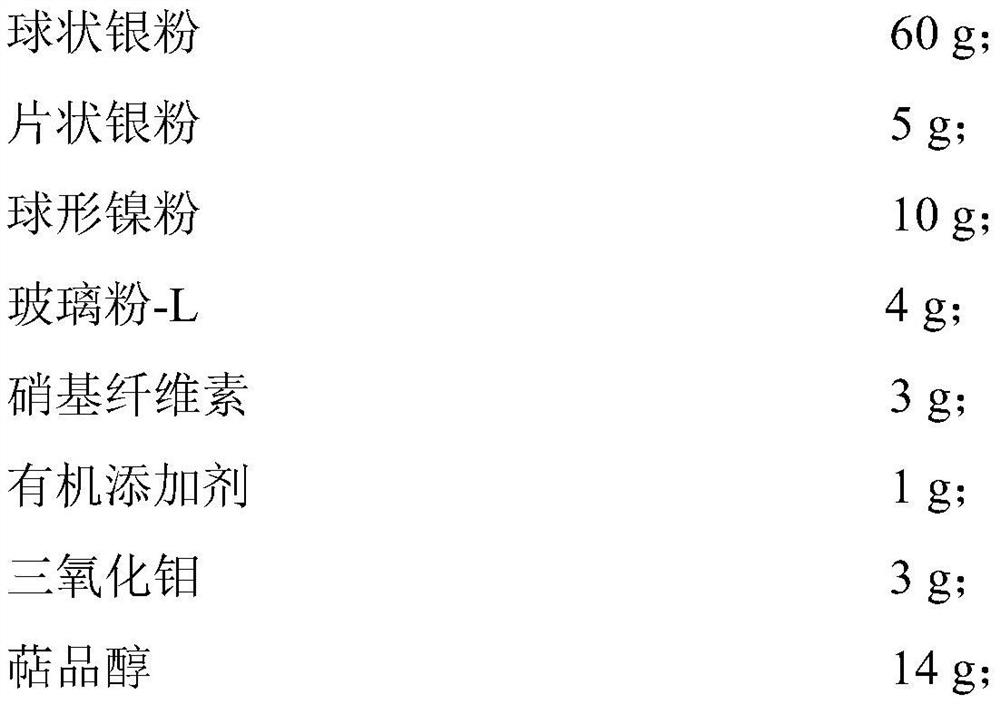

[0043] (1) Prepare 100g of raw materials, prepare raw materials according to the following components and quality:

[0044]

[0045] The particle size of the spherical silver powder used is 2.8 μm, and the tap density is 3.8 g / ml; the particle size of the flake silver powder is 6 μm, and the tap density is 2.4 g / ml;

[0046] The particle size of the spherical nickel powder used is 2.5 μm, and the tap density is 2.8 g / ml;

[0047] The composition and percentage of glass powder-L used are: 70% Bi 2 o 3 , 16%B 2 o 3 , 8% ZnO, 3.5% SiO 2 , 1.5%Al 2 o 3 , 1.0%Na 2 O;

[0048] The organic additives used were 0.5 g dioctyl phthalate and 0.5 g silicone resin.

[0049] The molybdenum trioxide used was of analytical grade.

[0050] (2) Preparation of carrier: Weigh nitrocellulose and terpineol, then heat it up to 80°C and keep the temperature constant. After the nitrocellulose is completely dissolved, filter and remove impurities on a mesh cloth of 300-400 mesh. That is, t...

Embodiment 3

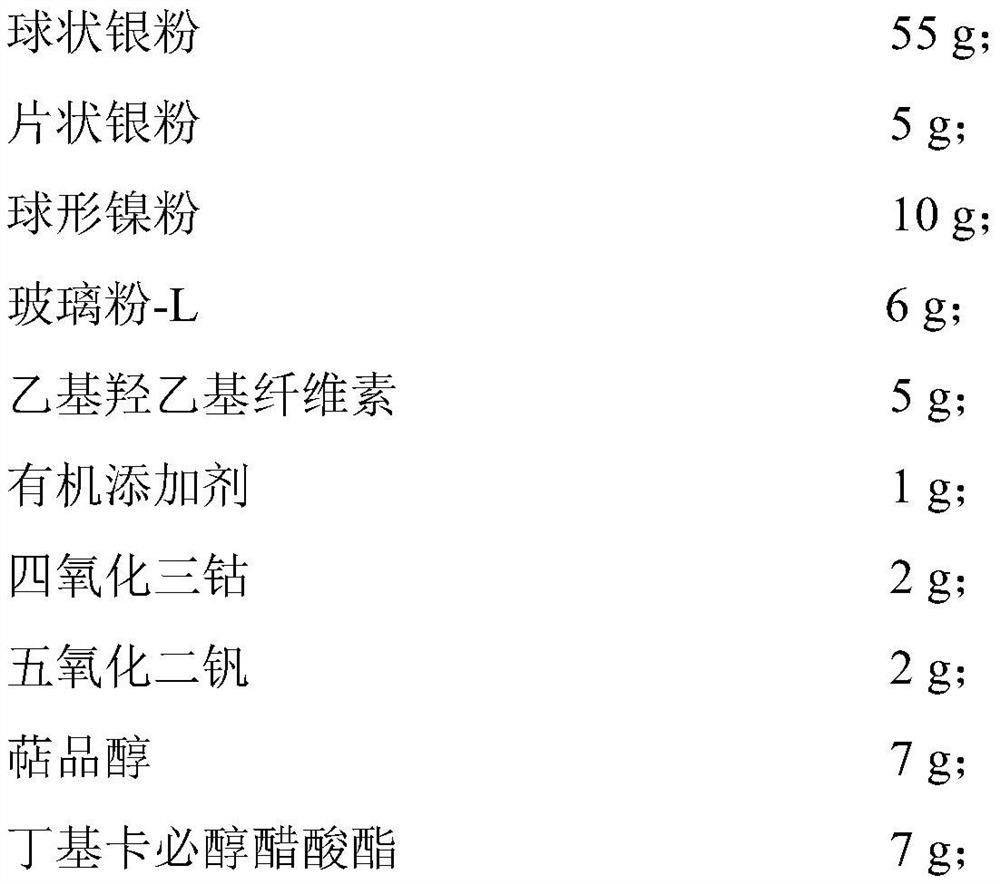

[0054] (1) Prepare 100g of raw materials, prepare raw materials according to the following components and quality:

[0055]

[0056] The particle size of the spherical silver powder used is 1.8 μm, and the tap density is 2.6 g / ml; the particle size of the flake silver powder is 7.5 μm, and the tap density is 1.9 g / ml;

[0057] The particle size of the spherical nickel powder used is 2.5 μm, and the tap density is 2.8 g / ml;

[0058] The composition and percentage of glass powder-L used are: 70% Bi 2 o 3 , 16%B 2 o 3 , 8% ZnO, 3.5% SiO 2 , 1.5%Al 2 o 3 , 1.0%Na 2 O;

[0059] The organic additives used are 0.6g tributyl citrate, 0.2g hydrogenated castor oil and 0.20g silane coupling agent KH570. The tricobalt tetroxide and vanadium pentoxide used are of analytical grade.

[0060] (2) Preparation of the carrier: weigh ethyl hydroxyethyl cellulose, terpineol and butyl carbitol acetate, then heat them up to 80°C and keep the temperature constant until the ethyl hydroxye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com